The New Range of 3D Laser Printers is About to Personalize Your World

First came 2D printers, then came 3D printing, and now the technology has stepped up to a new level. Welcome to the world of 3D laser printing. There is plenty to get excited about too, as you’re about to find out. Before we dive into 3D laser printing, let’s pause for a moment. It’s important to look at why 3D printing, in general, has become such a buzz word in modern times.

Additive Manufacturing Vs Subtractive Manufacturing

Laser 3D printing is a process called “subtractive technology.” Laser beam machining, or LBM, is a less-traditional subtractive manufacturing method than computer numerical controlled (CNC) milling. LBM uses light beams no thicker than a human hair. These lasers have the ability to engrave, cut, and shape 3D parts with meticulous precision. Even more impressive is that they can do this from a whole range of interesting and exciting flat sheet materials, usually with the push of a button. A computer directs the printer’s laser so that it follows the exact cutting line of the digital design. These lasers are high precision and leave behind a perfect 90 degree cut.

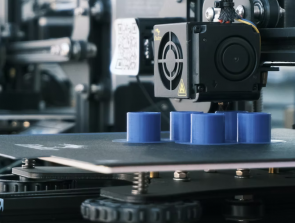

A regular 3D printer is different as it doesn’t use lasers to create its parts, it uses extruders. The job of the extruder is to first melt, and then precisely deposit exact slices of the chosen material to build the object—one layer at a time. It’s where the term “additive manufacturing (AM)” comes from.

Laser Cutting and Engraving

There are plenty of professional uses for 3D laser printers. For the home user, however, most of us like the idea of creating unique, personalized products, either for ourselves or as gifts for others. Thanks to 3D laser printing technology, laser cutting and laser engraving can now be under your control. You have the potential to design and produce your own personalized Items. These may include things like art, luggage, furniture, electronics, jewelry, toys, leather goods, and containers. The list could go on.

The Workings and Restrictions of 3D Laser Printers

Many of you reading here will already be familiar with basic 3D printers and printing technologies. The way these printers work have something in common to a CNC milling machine. They both have robotic heads which move around X, Y, and Z axis based on a mechanical, computerized system. That’s where the similarity ends.

CNC milling creates its parts from a block of material, usually plastic, wood, or some metal. In the manual world this would be the work of a sculptor. 3D laser printing is not capable of replacing a milling machine head. This is because it’s restricted. It just can’t cut through thick materials or highly reflective surfaces. Some of the newer 3D laser printers come equipped with a milling head add-on. The manufacturers of these costly machines call them all-in-one 3D printer combos. They come equipped with a 3D printer, a 3D scanner, a laser engraver, and/or a CNC mill. At the time of writing, all-in-one 3D printer combos are both rare and pricey. There are some cheaper combos that don’t include the milling capability. We’ll look at a few of those shortly.

A 3D laser printer comes into its own for creating the following:

- Cutting cardboard or balsa

- Engraving PCBs

- Creating complex pictures

- Creating professional stencils

Milling technology is not able to produce the objects above with the same precision as 3D laser printers. If it could, there would be little need for 3D laser printing.

The Best All-In-One 3D Laser Printers of 2017

The technology in this area is changing fast. As the technology improves and demand goes up, prices continue to come down. This is great news for home users, small businesses, local schools and libraries on a tight budget. The list below highlights some of the best all-in-one 3D laser printers for 2017. There will be others, but these are the best six picks so far, based on consumer reviews.

#1 ZMorph 2.0 SX Advanced

- TARGET AUDIENCE: Advanced level user

- BUILD VOLUME: 250 x 235 x 165 mm

- TECHNOLOGY (MANUFACTURING METHODS): 3D printing—Dual 3D printing—CNC milling—laser cutting, laser engraving

- MATERIALS: 3D printing: PLA, ABS, PVA, HIPS, nylon, rubber, ceramics, food—CNC mill: wax, Plexiglas, rubber, EVA foam, wood—Laser cutting/engraving: wood, leather, Plexiglas, PVA foil, paper, cardboard

- AVERAGE PRICE: $3,440

- PRICE CHECK: Link here

#2 XYZprinting Da Vinci 1.0 3-in-1

- TARGET AUDIENCE: Beginner level user

- BUILD VOLUME: 150 x 150 x 150 mm

- TECHNOLOGY (MANUFACTURING METHODS): 3D printing, Dual 3D printing—CNC milling, laser cutting, laser engraving

- MATERIALS: 3D printing: PLA, ABS, PVA, HIPS, nylon, rubber, ceramics, food—CNC mill: wax, plexiglas, rubber, EVA foam, wood—Laser cutting/engraving: wood, leather, plexiglass, PVA foil, paper, cardboard

- AVERAGE PRICE: $726

- PRICE CHECK: Link here

#3 FABtotum

- TARGET AUDIENCE: Intermediate level user

- BUILD VOLUME: 214 x 236 x 242 mm

- TECHNOLOGY (MANUFACTURING METHODS): 3D printing—CNC milling—laser engraving—3D scanning

- MATERIALS: 3D printing: PLA, ABS, nylon—CNC mill: wood, metal, foam

- AVERAGE PRICE: $1,400

- PRICE CHECK: Link here

#4 BoXZY

- TARGET AUDIENCE: Advanced level user

- BUILD VOLUME: 165 x 165 x 203 mm

- TECHNOLOGY (MANUFACTURING METHODS): 3D printing—CNC milling—laser engraving

- MATERIALS: 3D printing: PLA, ABS—CNC mill: wood, plastic, metal—laser engraving: wood, metal

- AVERAGE PRICE: $3,380

- PRICE CHECK: Link here

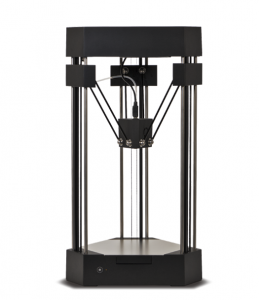

#5 Flux Delta

TARGET AUDIENCE: Beginner level user

BUILD VOLUME: 168 T x 208 H mm

TECHNOLOGY (MANUFACTURING METHODS): 3D printing, laser engraving, drawing, and 3D scanning

MATERIALS: 3D printing: PLA—laser engraving: PCB, wood, leather

AVERAGE PRICE: $1,999

PRICE CHECK: Link here

It’s Just the Beginning

Another name to look out for includes Glowforge Pro, priced around $3,995. As mentioned earlier, all-in-one laser printers in particular are still quite rare, but they won’t be for much longer. If you have creative ideas that need engraving or cutting to perfection, then it’s time to think about 3D laser printing. If you’re not ready to invest in your own printer just yet, don’t let that hold you back. You can still design whatever’s on your mind and send your digital files and ideas into one of the many 3D printing services. You can find these online or maybe even in your community. Your local library or colleges are two places that are certainly worth checking out.