How to 3D Print Without Buying a Printer

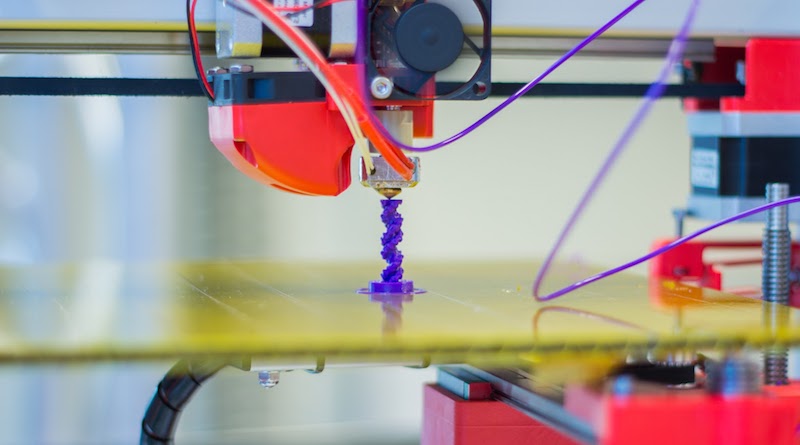

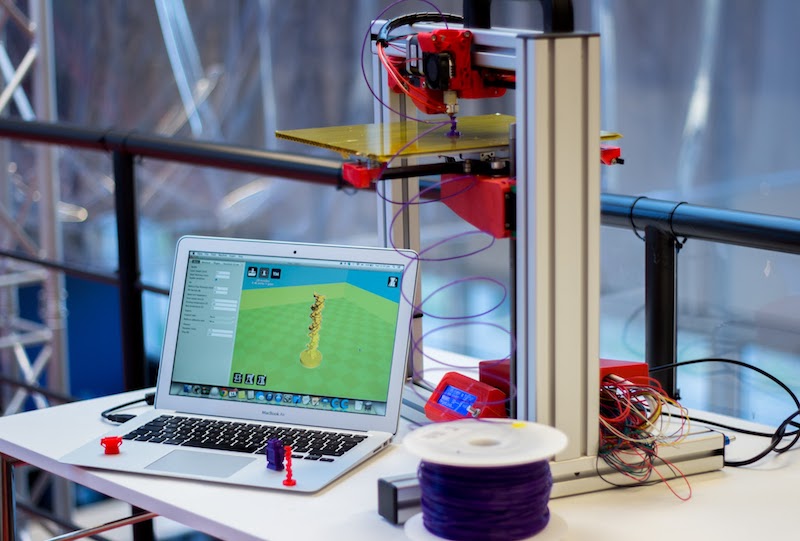

The latest phenomenon in modern technology is 3D printing, AKA additive manufacturing. It’s popular for all kinds of applications in all sorts of industries. Best of all is that this once costly technology is now available to Joe Average—that’s you and me. It’s a smart process that converts digital 3D models into real-world solid objects. It does this by building them up in multiple layers using a variety of special materials. These include thermoplastics, thermoplastic composites, ceramics, metal alloys, pure metals and others. But then you probably already know this if you’re looking to print in 3D.

Although 3D printing seems magical, it’s not without limits. You’re not going to leave it running overnight and wake up to a brand new Kindle eReader, computer tablet or smartphone. In other words, they’re not the dream devices that will make all those things you would normally buy. They’re amazing for all kinds of applications, but it’s important to know their limitations.

The Falling Cost of 3D Printing

It’s true, 3D printers and printing prices have fallen from thousands of dollars to just a few hundred in the last couple of years. Despite this, it’s still pricey for someone who can’t justify the cost. Don’t forget, you still have to invest in the printing materials as you would have to buy ink for an inkjet printer or toner for a laser copier. You wouldn’t want to invest in a 3D printer to create one or two small items like game pieces, toys, a figurine or some bust, etc. Despite the drop in price, though, 3D printers are still too expensive to leave on a shelf gathering dust, which brings us on to our main topic.

You Don’t Have a 3D Printer

OK, let’s say you have something you want to print in 3D but you don’t have a 3D printer. The good news is that you don’t need one. There are plenty of people and places out there today that can provide you with a 3D printing service, both online and off. However, there is a word of warning: it’s best to know a little something about the technology before you press ahead.

Here’s the lowdown on what you should know about 3D printing:

- Understand the different types of 3D printing technologies (see below)

- Know your 3D model, and what 3D printing processes will work best with it

- The volume of your model determines its price

- 3D printing prices rise considerably with object size

- Estimate your price as a starting point

- Not all 3D printing services are equal. Be sure to shop around

- Only take action once you’re able to make an informed decision (mistakes can cost)

The Cheapest Way to Print in 3D

Owning a 3D printer right now is not the most economical way to print in 3D. The cheapest way is to know someone—or know of someone—with a 3D printer. If you don’t know anyone, there are plenty of good websites that can put you in touch with some person or some outfit that can help. 3D Hubs and Make-XYZ are two of many such websites. A quick search on Google should result in a bunch of local 3D printing services in your immediate area. Heck, you could even find 3D printers at the local library or a nearby college as two examples.

A simple online search like this should help (including quotes):

“3d printers” “City Name”

Paying to Print Online

There’s another option to print your file if for whatever reason you don’t want to bum on someone else’s 3D printer for free. There are online services that specialize in printing 3D objects. Usually, they can print cost-effectively since it’s their bread and butter. The top providers right now are Sculpteo, I.materialize, and Shapeways. Currently, the cheapest of them is Sculpteo where you can print and object the size of an iPhone case for around $3. Don’t forget, you have to pay for shipping too which will double the cost.

What Are You Paying For?

Whatever the size of your project, you want to get it 3D printed. And the reason is because you’re unable to just go out and buy whatever the item is. If you think the price is high, think how much you want the item. What you’re getting is a custom manufactured product, made to your specific request. You get it made hassle free, on demand, because you requested it. The best way to learn and appreciate 3D printing is to hold the end piece in your hand, knowing that it came from your 3D model.

My Project Is BIG

If your project is big it’ll be costly. And the more complex it is, the more you will have to think about the type of 3D printing it will need. This is no time for searching for the cheapest price. If you haven’t got to grips with the various 3D printing technologies, then please make sure you do. It’s also important to understand the different materials used, and what you need for your model. It’s beyond the scope of this article to cover these 3D printing processes in detail, but I will list them for you.

Here’s a quick list of the seven current technologies, or 3D printers:

- Digital Light Processing(DLP)

- Electronic Beam Melting (EBM)

- Fused deposition modeling (FDM)

- Laminated object manufacturing (LOM)

- Selective laser melting (SLM)

- Selective Laser Sintering (SLS)

- Stereolithography(SLA)

You’re a Layman

Like all technologies, there’s a lot of technical jargon used in the 3D printing industry. Don’t worry if you’re not a tech-head. All you need to know is the technology (process and equipment) that will best work with your project. As long as the person or company understands this technology, they shouldn’t throw any overly technical questions at you. In other words, the printer (the person, not the machine) should check all your details before proceeding. They will also correct any issues to prevent any printing errors. If someone keeps throwing techie questions, either your file is impossible to understand or they’re not qualified to do your job. In the latter case, you need to cancel the work before it starts and move on. If your problem is with your 3D model, it’s back to the drawing board, which brings me on to the final point.

Your 3D Model

Creating your first 3D model (also three-dimensional modeling) might sound daunting, but it doesn’t have to be. You can learn how to use special, user-friendly software that will turn real life objects into 3D print models that are ready to go. Alternatively, you can buy your model or choose from the thousands of free downloads at one of the many online databases or vast 3D catalogs.

Conclusion

So there you have it—a quick and simple introduction into what 3D printing is. You should now know what you have to learn (the basics), and how to get started. You really don’t need to invest in a 3D printer to print in 3D. In fact, for the majority of folks it’s a waste of time and money. That’s unless you intend to turn it into a business venture and profit from your endeavors.