How Much Does 3D Printing Cost?

Not all 3D printers, 3D objects, printing technologies, materials, and user expectations are equal. The costs for your purposes can vary from a few dollars to tens of thousands. Even so, the price of 3D printers and 3D printing has fallen in recent years by a huge amount. It was once the tool of scientists, engineers, and various industries, but not anymore. That said, it’s still too expensive to justify in most homes. It’s not too expensive, though, for hobbyist, schools, libraries, and the like. Perhaps you expect to print lots of 3D models on a regular basis, either for self-enjoyment or to make money? If so, then it makes sense to buy your own printer.

If you intend to dabble without getting too serious, then there are more cost-effective ways to print in 3D. We’ll look into all these things in this guide. Another concern people have is with the electricity costs of a 3D printer. There’s no short answer for this as it depends on a range of factors (see below).

How Much Power Do 3D Printers Use?

The amount of power a 3D printer uses is contingent on many factors. Most 3D printers share similar powered components. These include cooling fans, stepper motors, a hot end for melting materials, and a heated build platform. But the size of a printer, the age of the machine, its speed, technology, and the materials used, will also play a part. For the average home user, there shouldn’t be any nasty surprises with the electricity bill. For commercial use, though, you may want to discuss the running costs with the manufacturer before making any decisions on a particular model.

Ways to Keep the Cost of 3D Printing Down

If you were printing text and images using an inject printer and wanted to save on printing costs you would know what to do. If quality wasn’t the utmost priority you’d choose cheaper paper. Then you might decide to print in greyscale and or even at draft quality. There are various ways to keep the cost of 3D printing down too. Here are six of our top tips:

- Invest in your own printer (see above)

- Choose the most cost-effective 3D printing material

- Reduce the size and volume of your 3D model

- Use an online 3D printing service to print your models for you

- Use a price comparison service before you commit to the above

- Make use of free designs or modify a free model

- Cost of 3D printers (updated 2017)

1. Invest in Your Own 3D Printer

3D printing technology is changing so fast it’s hard to keep up. As mentioned in the opening paragraph, not everyone can justify buying their own 3D printer. Those of you who want to have your own machine at least have affordable options today. We’ll look at a few of the hot models of 2017 later. We’ll start with a few of the most costly, high-end 3D printers first, and then work down to the budget end machines. Note that this is not a comprehensive 3D printer review guide per se. We’ll highlight the key features for each model and link out to review pages that offer more details.

What to Look for Before Buying a 3D Printer

Before you even consider buying your own 3D printer, you’ll need to know what to look for. This means some knowledge on the machines, their capabilities, and their restrictions. What goes onto your shortlist all depends on the kinds of things you plan to print in 3D. You also need to consider your expectations going forward. 3D printing is a pretty broad term, and it can mean different things to different people. For hobbyists and small operations, the most popular technology is FDM or Fused Deposition Modeling. This process uses ultraviolet light beams to harden liquid materials. SLS (Selective Laser Sintering) is another popular choice. Instead of using a UV beam, it uses lasers and powders to perform the job.

If you’re not familiar with 3D printers and printing technologies, don’t worry. You can read our detailed guide ‘The Different Types of 3D Printing Technologies’ before continuing.

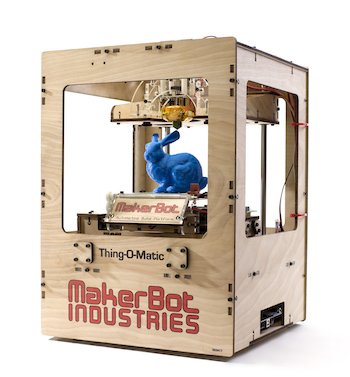

Build your own – tinker with technology

Yes, you even have the option to build your own 3D printer if that appeals to you. There is no shortage of creators and makers in the 3D printing community to support your efforts. It’s not everybody’s cup of tea, but for those who want to learn about the technology from the ground up, this is a great way to do it. You can buy 3D printer kits online which all come with step by step instructions. Not only is this an education, but you’ll also save money in the process. Before you take this route, make sure you choose a printer with the print quality that meets your expectations.

You Get What You Pay For

Once you know the type of printer and printing materials you expect to use, it’s time to shop around. Always be mindful of your expectations as you do this. A general rule is that you get what you pay for. In other words, the higher the price, the more options there are for printing, and the output quality is better.

If you only plan to build small objects that are not overly complex, the quality may not be such an issue. But if you expect to print complex models of varying sizes, then you need to be more selective. It’s quite possible to get a 3D printer for around $100 these days. You won’t be winning any awards with the printed parts, but it’s a great way to dip your toe in and play around until you become more familiar with things.

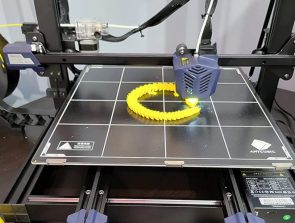

2. Choosing 3D Printing Materials

All 3D printers need 3D materials (3D inks), also called filaments. And like regular inject printers, you will need to buy these separately. For everyday 3D printing, there are two materials you’ll become familiar with. One is PLA (full name, Poly Lactic Acid) and the other ABS (Acrylonitrile Butadiene Styrene). Both of these materials are what we call thermoplastics. They work by becoming soft and flexible as the printer heats them, and then return to a solid state the moment they cool down. You can buy PLA and ABS online in 2.2lbs (1kg) spools of filament. The prices may vary a little, but expect to pay somewhere in the neighborhood of $30 per spool.

3. Reduce the Size and Volume of Your Model

Ask yourself whether your printed 3D model needs to be the size you have designed it. If it will serve its purpose at a smaller scale, then you will save on materials. All 3D printing is volume based, so the less material you use, the less the output model will cost. Downsizing the object will not always be possible of course. The good news is that downsizing is not the only hack you have for cost saving.

Hollowing Your Model

Hollowing a 3D part may still produce the object you want but with a considerable saving on material. If you can reduce both the size and hollow it out, the savings are even greater. Another plus point is that hollowing models with some materials may even prevent deformations. The only downside to hollowing 3D objects is that it can take practice. This is particularly the case with more complex parts. If you decide to use a 3D printing service, you may still have to prepare your designs. This means you need to become familiar with 3D modeling software. You can also find services that will design your model for you, based on your specific requirements. Note that not all 3D modeling programs work in the exact same way. With some, hollowing will be easy, whereas others may be a bit trickier.

The object’s wall thickness needs to be strong enough to protect your part from breaking. You may also want to add ‘escape holes’ for some designs. Escape holes allow you to remove any trapped material that gets into the part’s interior during the build process. One way to remove excess material is by using pressurized air.

You can check out the different software programs and choose the one that bests suits your needs. Start by looking at the free Autodesk software called Meshmixer. There are others, but this one is particularly good for hollowing 3D models. All you do is add your 3D file, select ‘Edit’ from the menu, followed by ‘Hollow’. That’s about it, at least at the basic level.

Tip: You can create your own models, download free ones, or modify other people’s projects. There’re plenty of free easy-to-use 3D design tools to get you started. Tinkercad is one worth considering.

4. Using a 3D Printing Service

It’s quite possible to get into 3D printing without a 3D printer. There are some good quality 3D printing services online that can produce your 3D models for a price. This is a cheap way to enjoy the technology if you only plan to dabble once in a while. If, however, you want more control and plan to do a lot of 3D printing, then it’s better to invest in your own machine and materials in the long term.

Buying a 3D Printer Vs Using a 3D Printing Service

Your question is this: should you buy a 3D printer or use a 3D printing service? You might have already made your mind up, but those of you still on the fence will want to keep reading. Part of the answer to your question refers to quantity. It makes no sense to invest in a machine and materials if all you want to do is print a single object or a small handful of items. Even if you have a genuine interest in the technology, you may want to use a 3D printing service at the beginning. This way you get to see if you have a lasting passion or whether it’s just a passing fad. There’s a good chance you’ll get the bug, but it’s always a good idea to test the waters before diving in head first.

Adding Up the Costs of 3D Printing

The type of 3D printer and materials you use matters when it comes to costs. Are you looking to produce high-quality objects of various sizes? If yes, then you will need to find the total cost to print, and then compare it with a 3D printing service. It’s a simple equation that will look something like this:

- Add all the investment cost together (printer, materials, etc)

- Your time—hourly rate—if you charge for printing 3D objects

- All consumables

- Divide the above costs by the number of objects

If you expect to print lots of objects for other people, as a business, don’t forget to add the maintenance and replacement parts to the total costs, including shipping. The more you print and the longer the period, the easier it is to get a clear picture of how much it costs to produce 3D parts using your own resources. All you have to do then is find out how much the parts would cost using one of the many 3D services online or in your local community.

Not All 3D Printing Services Are Equal

There are many 3D printing services online, but you could also find some in your local area. If the price is right, local services will work out better as you won’t have to wait for postage. It’s also less hassle to take the part(s) back if there are any problems. You get to have face-to-face meetings with local services to, which is something a lot of people prefer.

One unlikely place that’s proving to be a godsend for 3D printing enthusiasts is the local library. A simple search online should soon let you know if there’s one in your area offering the service. Another great local service might be a Hackerspace.

Hackerspace

A Hackerspace, also known as a hacklab, is quite a new concept. These are shared workspaces with a difference. They exist to help people accomplish DIY projects that they can’t do at home for various reasons. This is usually because they don’t have the tools or the expertise to do whatever it is they’re working on by themselves. A well-run Hackerspace doesn’t only have tools, but also training classes and a network of people qualified in all kinds of areas. There’s a lot of voluntary help in these spaces—likeminded people—happy to assist those who need a hand. Some Hackerspaces include 3D printing as part of their setup. Make sure you look for a Hackerspace operating in your area if it interests you.

Online Services

Online 3D printings services are everywhere these days, with new ones popping up all the time. Professional 3D printers run these places—people who know what it takes to bring your ideas to life. Some will even take your idea and run with it, meaning you don’t even have to supply the 3D model (digital design file). These services are perfect for people who want the 3D parts but have no interest in the technical side of things. For smaller models, online 3D printing services usually promise delivery within around three days or so. We’ve included a few services below for you to explore, but there are others, so feel free to do your own research.

A few 3D printing services to consider include:

All hobbies cost something. If you want your own 3D printer and are happy to pay the price, then there’s nothing more to say. If cost is a concern, then you can always look at one of the cheap 3D printer kits. This will allow you to build your own machine and dabble with the technology at your leisure. The main point is to know all the costs of DIY 3D printing vs printing services before you commit to anything. Also, make sure you know what your expectations are.

Look for the following services as they apply to you:

- Does the service offer design assistance, if you need it?

- Do you get to choose the materials for your project?

- Does the service provide the 3D printing techniques you want?

5. Use a Price Comparison Service

It makes sense to compare prices for 3D printers, materials and/or 3D printing services. Despite this, a lot of people often go for the first 3D printer or printing service that impresses them and matches their budget. This is a big mistake that can cost you dearly. Seriously, there can be huge differences, so make sure you shop around.

How Do You Know You Are Getting a Competitive Price?

It’s a good question and one that has a simple answer. Once you know what type of 3D printer or 3D printing service you need, go to an online 3D comparison service. A good one—for online services—at the time of writing, is 3D Printing Price Check. You can upload your STL file and get prices right away from a few of the major services.

6. Make Use of Free Designs

There are so many online communities that offer free, 3D models. Some, like Pinshape, even allow you to sell your own designs if they’re worth something. It’s amazing how imaginative some of these 3D creations are. If you’re short on time, or you want to start from the bottom up with 3D printing, this is the way to go. You can make use of free designs as a way to save both time and money. You can also download designs and modify them so that they’re unique to you and your needs.

As you can see, 3D printing doesn’t have to be the high-cost hobby that many think it is. There are all sorts of hacks to help you print in 3D in a more affordable way.

7. Cost of 3D Printers (Updated 2019)

Although this is a guide more for the hobbyist, or small concern looking to saving money, we’ll still include a few high-end industrial 3D printers in this section. This way we’ll have something for all readers, and it also shows 3D printing enthusiasts the full range of technologies. So this section is a short introduction to the various popular models ranging from high, mid, and low budget machines.

Remember, the technology for 3D printing and printers is developing all the time. That means things can get outdated quickly. Because of this, we’ll update this guide periodically to keep up with the times.

The Best Budget-Range 3D Printers

Below are the five most popular budget 3D printers. In this section, we’ll look at 3D machines under the $600 price range. These are great devices for anyone who wants to learn about and experiment with, 3D printing technology. Depending on your models and expectations, some of these cheap 3D printers can produce impressive objects for the money.

Five of the top budget-range 3D printers include (in order of price, lowest to highest):

1. XYZ Da Vinci Jr. 1.0 Budget-Range Printer

STARTING AT: $199

The Da Vinci 1.0 is a complete Taiwanese 3D printer at the low-budget end. It’s a perfect choice for hobbyists, small businesses and for educational purposes. Despite its low price tag, the Da Vinci 1.0 is made from high-quality construction and one of the best-valued machines in its price range. Anyone just starting out in the world of 3D printing will not be disappointed with this model. It’s a real plug-n-play device right out-of-the-box. That means there’s no awkward assembly for you to bother with, nor any adjustments to the equipment.

Printer’s key features include:

- Printer technology: FDM

- Materials: ABS, PLA

- Build volume: 20 x 20 x 19 cm

- Minimum layer height: 100 microns

- Maximum layer height: 400 microns

- Extruder head: One

- Printing speed: 150 mm/s

- Heated platform: Yes

- Filament diameter: 1.75

- On-printer control panel: Yes

- Connectivity: USB

The Pros

- Build volume

- User-friendly

- Heated platform

- Low price

- Good build quality for the money

The Cons

- Precision

- Material availability

- Software

- Not open source

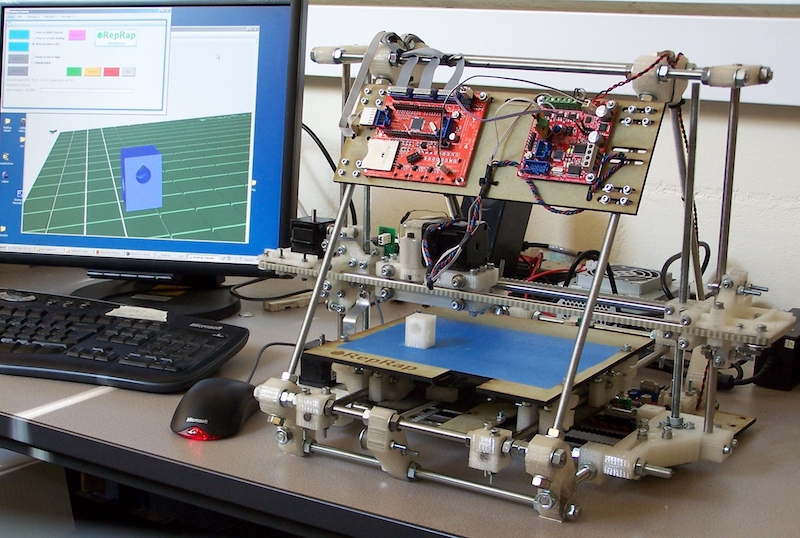

2. Prusa i3 Budget-Range Printer

STARTING AT: $269

The Prusa i3 is the newest of the DIY 3D printer models developed by the RepRap 3D printer family. As a fully open source project, the printer can take on many different sizes and forms. Don’t let the machine’s simplicity fool you. You can imagine, draw, and then transform many of your ideas into physical 3D objects with this device. If you’re just starting out, don’t worry. There are plenty of assembly guides around, and lots of helpful people within the supportive community.

Printer’s key features include:

- Printer technology: FDM

- Open source: software and hardware

- Materials: ABS, PLA

- Build volume: 20 x 20 x 18 cm

- Minimum layer height: 50 microns

- Extruder head: One

- Third party materials: Yes

- Heated platform: Yes

- On-printer controls: Optional

- Connectivity: USB

The Pros

- Maintenance

- Community

- Material availability

- Fully open source

- Affordable price

The Cons

- Build quality

- Precision

- Bit fiddly for the novice

- Speed

- Design

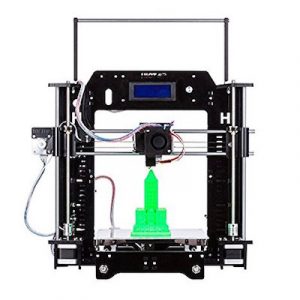

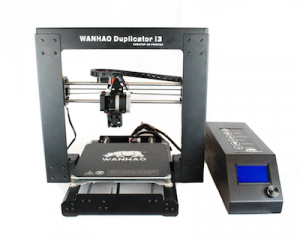

3. Wanhao Duplicator i3 Budget-Range Printer

STARTING AT: $399

Forget assembling, calibrating, and testing. The Wanhao Duplicator i3 is an affordable and very easy-to-use, versatile preassembled 3D desktop printer. It’s a perfect machine for entry-level enthusiasts. This is the cheaper version of the original Prusa i3 model. The Wanhao’s Duplicator i3 V2 is one of the most liked repraps (Replication Rapid-Prototyper) projects around and for good reason. The steel chassis improves overall stability and life of the printer. The output quality is impressive for the under $400 price range.

Printer’s key features include:

- Printer technology: FDM

- Materials: ABS, PLA, Exotics

- Build volume: 20 x 20 x 18 cm

- Minimum layer height: 100 microns

- Filament diameter: 1.75

- Extruder head: One

- Third party materials: Yes

- Heated platform: Yes

- Open source: Software

- Connectivity: USB, SD Card

The Pros

- Maintenance

- Build volume

- The heated platform

- Good price

The Cons

- Print quality

- Build quality

- Noise level

- Customer support

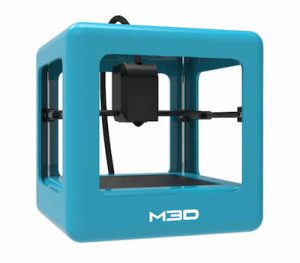

4. M3D Micro Budget-Range Printer

STARTING AT: $499

The Micro by M3D is a great little 3D printer for serious people on a tight budget. It’s also appealing because of its small size and light weight (2.2 pounds). This machine was, in fact, the most successful of the FDM printers that appeared on Kickstarter back in its day. It retains its popularity not least because it’s reliable, consistent, and easy to operate.

Printer’s key features include:

- Printer technology: FDM

- Materials: ABS, PLA

- Build volume: 11.6 x 10.9 x 11.3 cm

- Minimum layer height: 50 microns

- Maximum layer height: 350 microns

- Extruder head: One

- X-Y precision: 15 microns

- Third party materials: Yes

- Filament diameter: 1.75

- Connectivity: USB

The Pros

- Design

- Ease of use

- Noise level

- Maintenance

- Price

The Cons

- Print quality

- Software

- Printer Speed

- No heated platform

- Not open source

5. UP Mini Budget-Range Printer

STARTING AT: $599

This is a simple, yet reliable and affordable 3D printer. Like many of the best budget end 3D printers, the Mini 3D machine is ready to go straight out of the box. Even a novice can start to print their first model in less than 15 minutes. Temperature remains consistent throughout printing, thus providing a constant printing environment. The objects are not exceptional, but they’re still a good average quality nonetheless. This is a perfect machine for anyone dabbling with the technology for the first time.

Printer’s key features include:

- Printer technology: FDM

- Materials: ABS, PLA

- Build volume: 12 x 12 x 12 cm

- Minimum layer height: 200 microns

- Maximum layer height: 350 microns

- Extruder head: One

- Third party material: Yes, but with limitations

- Heated platform: Yes

- Filament diameter: 1.75

- Connectivity: USB

The Pros

- Design

- Ease of use

- Reliability

- Software

- Price

The Cons

- Precision

- Build volume

- Proprietary materials

- Not open source

The Best Mid-range 3D Printers

Below are five of the most popular mid-range 3D printers. Here we’ll classify ‘mid-range’ as those machines which typically sit somewhere between the $800-$1,500 price range. 3D printers in the mid-range attract the serious hobbyist, schools, libraries, and small businesses, etc. Obviously mid-range printers cannot complete with high-end industrial models, but don’t let that put you off. Despite the thousands of dollars difference, mid-range 3D machines still bring a lot to the table.

Five of the top mid-range 3D printers include (in order of price, lowest to highest):

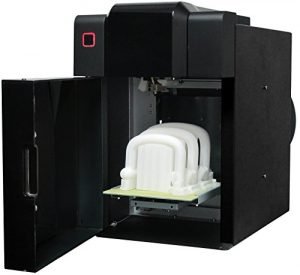

1. The FlashForge Creator Pro Mid-Range Printer

STARTING AT: $899.00

This mid-range 3D printer is a Chinese machine that comes complete with an enclosed chassis and a metal frame. Compared to its predecessor, this model has gone through some useful upgrades. These have improved both its durability and stabilization. 3D printing enthusiasts like the FlashForge Creator Pro because it’s open source. It means there are plenty of opportunities for continued experimentation and upgrades, which allows the user to get the most out of this machine.

Printer’s key features include:

- Printer technology: FDM

- Materials: ABS, PLA, Exotics

- Build volume: 22.5 x 14.5 x 15 cm

- Minimum layer height: 100 microns

- Maximum layer height: 500 microns

- Extruder head: Two

- X-Y precision: 11 microns

- Printing speed: 40-100 mm/s

- Open source: Software and hardware

- Third party materials: Yes

- Heated platform: Yes

- Filament diameter: 1.75

- On-printer control panel(s): Yes

- Connectivity: USB, SD Card

The Pros

- Build quality

- Reliability

- Dual extruder

- Value

The Cons

- Noise level

- Connectivity

- Software

2. The Afinia H-Series H480 Mid-Range Printer

STARTING AT: $1,000

The Afinia H-Series H480 is a 3D printer that has gone through some major improvements on the original H479. These upgrades have done a lot to improve both the overall performance and print quality. The machine comes fully-assembled out of the box and is ready to use in minutes.

Printer’s key features include:

- Printer technology: FDM

- Materials: ABS, PLA

- Build volume: 14 x 14 x 13.5 cm

- Minimum layer height: 150 microns

- Maximum layer height: 400 microns

- Extruder head: One

- Heated platform: Yes

- Filament diameter: 1.75

- Connectivity USB

The Pros

- Ease of use

- Precision

- Noise level

- Reliability

- Heated platform

The Cons

- Build volume

- Community

- Material availability

- Software

- Not open source

3. Printrbot Metal Plus 1505 Mid-Range Printer

STARTING AT: $1,199

This is without doubt one of the earliest innovators of 3D desktop printing, and today you still get a lot of bang for your buck. The Printrbot Metal Plus is a great machine for anyone who loves a simple, minimalistic type of design. The printer comes with a considerable build area and an improved linear rail system. It’s a sturdy device that offers a lot in a small package.

Printer’s key features include:

- Printer technology: FDM

- Materials: ABS and PLA

- On-printer controls: Optional

- Build volume: 25 x 25 x 26.5 cm

- Minimum layer height: 50 microns

- Extruder head: 1, 2 (optional)

- Printing speed: 80 mm/s

- Open source: Software & hardware

- Third party materials: Yes

- Heated platform: Yes

- Filament diameter: 1.75

- Connectivity USB, SD Card

The Pros

- Build volume

- Printer size

- Good customer support

- Great value for money

The Cons

- Design (unappealing to some)

- Printing speed

- Noise level

- Software

4. LulzBot Mini Mid-Range Printer

STARTING AT: $1,250

You can unbox this plug-n-play machine and have it up and running in 15 minutes or less. The LulzBot Mini is an extremely well-built 3D printer that’s both robust and reliable. It’s an open source project that boasts a huge online community. Here 3D printing hobbyists and professionals alike can swap and share ideas, tips, and solutions to problems, etc.

Printer’s key features include:

- Printer technology: FDM

- Build volume 15.2 x 15.2 x 15.8 cm

- Heated platform: Yes

- Extruder head: One

- Minimum layer height: 50 microns

- Maximum layer height: 500 microns

- Third party materials: Yes

- Printing speed: 275mm/sec

- Open source: Software and hardware

- Filament diameter: 3.00

- Connectivity: USB

The Pros

- Build quality

- User-friendly

- Material availability

- Customer support

- Open source

The Cons

- Build volume

- Connectivity

- Noise level

- Price

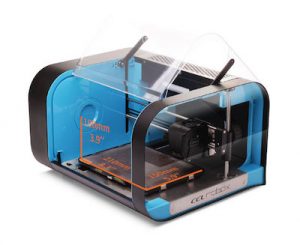

5. CEL Robox Mid-Range Printer

STARTING AT: $1,499

The CEL Robox is a great out-of-the-box 3D printer capable of dual material printing. This means it has the ability to print in two materials at the same time. The printer originated from a Kickstarter campaign, funded back on October 28, 2013. It’s remained a favorite choice for many ever since. The closed system helps to create a near-perfect environment for 3D printing, though one restriction is the model height. Right now, its limit is at just 10cm.

Printer’s key features include:

- Printer type: FDM

- Materials: PLA, ABS, MABS (clear), HIPS, and PETG

- Build volume: 21 x 15 x 10 cm

- Minimum layer height: 20 microns

- Extruder head: 1, 2 (optional)

- X-Y precision: 7.5 microns

- Third party materials: Yes

- Heated platform: Yes

- Filament diameter: 1.75

- Connectivity: USB

The Pros

- Good print quality

- Smart design

- User-friendly

- Customer support

The Cons

- Build volume

- Not open source

- Connectivity restrictions

Best High End (Industrial) 3D Printers

Below are four of the best industrial 3D printers available on the market today.

1. Objet Eden260VS Industrial Printer

STARTING AT: $50,000

The Objet Eden260VS is a top choice industrial 3D printer for a number of reasons. To begin with, it’s an economical machine and one with a small footprint. It’s quick and clean at producing accurate object fabrication. Output models are not only durable but smooth too, with ultra-fine details. This printer has wide-ranging uses but is particularly suited for the dentistry industry.

Printer’s key features include:

- Printer technology: Polyjet (multi-materials)

- Print speed: Two modes

- Print heads: One

- Build volume: 25.5 x 25.2 x 20 cm

- Minimum layer height: 16 microns

- Maximum layer height: 200 microns

- Resolution: 600 DPI

- Connectivity: Ethernet

The Pros

- High build quality

- High precision

- Build volume

- Printing speed

The Cons

- High running costs

- Material availability

- Not open source

- High price

2. ProJet 3500 HDMax Industrial Printer

STARTING AT: $70,000

This printer delivers exactly what you would expect from a machine of its kind. The 3D printed parts are quality plastic that are durable and robust. It also has a high-speed mode—faster compared to similar models within its range. It has a lot going for it and checks a lot of boxes.

Printer’s key features include:

- Printer technology: MultiJet

- On-printer control panel(s): Yes

- Material: Visijet

- Build volume: 29.8 x 18.5 x 20.3 cm

- Minimum layer height: 16 microns

- Maximum layer height: 32 microns

- Printing speed: Two modes

- Resolution: 600 DPI

- Connectivity: Ethernet

The Pros

- Print quality

- Build quality

- High precision

- Low noise level

The Cons

- Material availability

- High running costs

- High price

3. Objet260 Connex3 Industrial Printer

STARTING AT: $120,000.00

The Objet260 Connex3 is an industrial 3D printer capable of color and multi-material 3D printing. Within a single print job, users can incorporate a wide range of materials to vary translucency, rigidity, thermal resistance or color.

Printer’s key features include:

- Printer technology: Polyjet

- Build volume: 25.5 x 25.2 x 20 cm

- Minimum layer height: 16 microns

- Connectivity: LAN – TCP/IP

- Power requirements: 110–240 VAC 50/60 HZ

- Print heads: Eight

- Print speed: 12mm/h

- Resolution: 600 DPI

The Pros

- Prints complex forms, shapes, and geometries

- Prints paper-thin layers, providing detailed prototypes

- Fully curated models (no finishing required)

- Uses multiple materials and can print at the same time (no assembly required)

- Can design prototypes with multiple moving joints and parts

The Cons

- Support material not reusable, resulting in increased costs

- Removing support material from complex forms is time consuming

- One of the most expensive of all the 3D industrial printers

4. EOSINT P 760 Industrial Printer

STARTING AT: $250,000

This is a polymer laser sintering 3D printing machine. It has a bigger production volume than all the other additive manufacturing (AM) systems at the time of writing. Its impressive parallel laser system is able to print at considerably faster rates than other devices. Users find the EOSINT P 760 to be a consistent 3D printer and one that awards them with reliable, high productivity.

Printer’s key features include:

- Printer technology: SLS

- Build volume: 70 x 38 x 58 cm

- Minimum layer height: 60 microns

- Power requirements: 32 A

- Connectivity: Ethernet

The Pros

- High quality

- High efficiency

- Flexibility

- User-friendly

The Cons

- High price tag

If you’ve read through this guide, you will now have a much better understanding on 3D printers, printing, the materials, and costs. You will also know how to keep costs to a minimum and make better-informed decisions going forward.

I wonder what’s your opinion about Prusa MK3 printer. Does it deserve a recommendation? I am looking for a mid-range (~1000 Euro) 3D printer, and I am mostly concerned with quality and reliability (less so with speed). Thanks!

Yes, this is an excellent 3D printer. Please see our reviews:

https://3dinsider.com/diy-3d-printers/

https://3dinsider.com/original-prusa-i3-mk3-review/

“How Much Does 3D Printing Cost?”

So where’s the answer to the question you raise in all those pages of text? Can’t bothered reading all that!

Remember how you did lab tests at uni and you had to include a conclusion on the very first page? Think about it…