7 Facts About 3D Printing

The arrival of 3D printing promises to be the next big game-changer in the way industries around the world operate. But for such a significant technology, there are far too many misconceptions. Let’s try to clear up the confusion with some hard facts about 3D printing.

1. It’s Been Around Since the ‘80s

3D printing has gained mainstream popularity in the last decade, but it’s been around a lot longer than that. In 1984, Chuck Hill invented ‘Stereolithography’, a process which made use of UV lasers to solidify photopolymers. This technique was used to create 3D parts layer by layer. The technology took off within five years with many other companies mimicking the technique to print their own 3D models. The reason 3D printing became popular only recently is because it was around 2006 that 3D printers finally became compact and cheap enough to be manufactured for home use instead of needing to be housed within large factories.

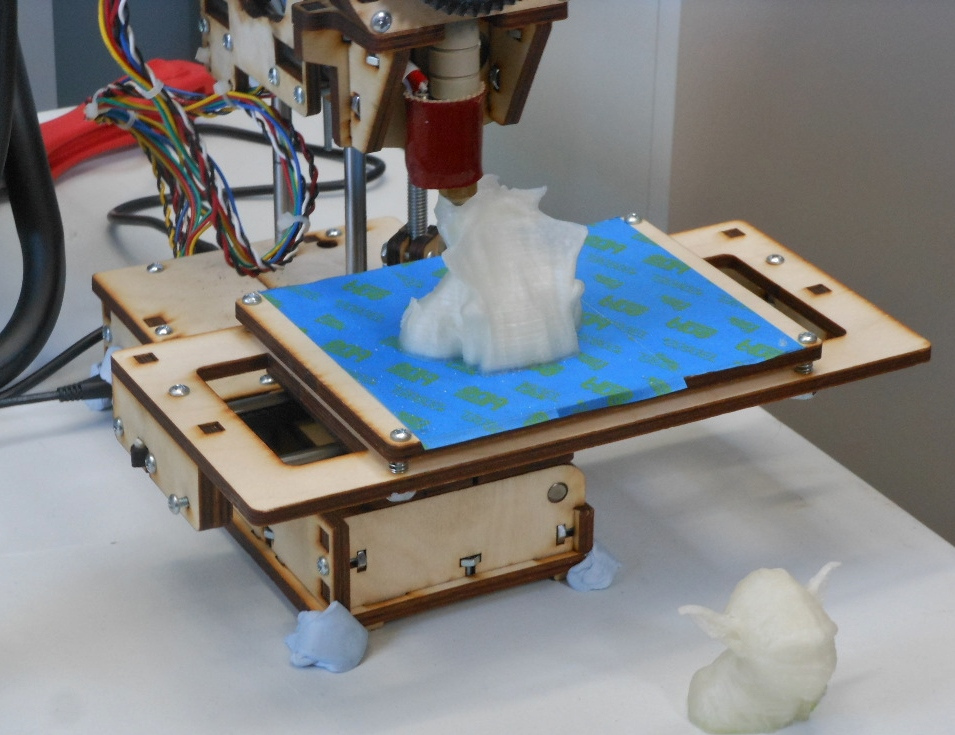

2. It Comes in Many Forms

3D printing can be carried out in a number of ways. The fused deposition (FDM) style of modeling allows for a plastic filament to be deposited in layers to fill the model shape. Stereolithography (SLA) uses a laser to cure resin and built the prototype layer by layer, removing the supports for the model once it solidifies. Finally, selective laser sintering (SLS) uses sinter powdered metal to create a solid metal structure.

3.The Maker Movement

A ‘Maker’ is someone who uses 3D printers to create any number of models. The term was first used by Chris Anderson in his book called ‘Makers’, which talked about the revolution being brought about by open source design and 3D printing. The maker movement has grown in size and scale. Today there is a global community of enthusiasts who make use of the internet to discuss the finer points of 3D printing and bounce ideas off of each other for their future projects.

4. Customized Modeling is Within Reach

For the longest time, makers were preoccupied with how they were going to print their next ambitious project. Now, the question has moved on to what should be printed next. Today’s printers allow for an unprecedented level of customization for the finished models, which means that you can use the printer to build replicas of customized toy parts, random designs, or anything else your heart desires. Many companies are already getting in on the action and are offering their services to build customized 3D parts on demand.

5. Different Types of Print Material

Another limitation that held 3D printing technology back for many years was the fact that for the longest time, there was only one type of polymer that could be used to create a model. Nowadays, a wide variety of new materials can be used to print 3D models including gold, silver, titanium, ceramics, and wood. Makers and 3D print companies are taking advantage of this variety to create more popular 3D print models of house parts, dresses, jewelry, drones, and much more. Most significantly, there has been important progress made in creating organic 3D printed models made up of living tissue to treat patients and create new limbs for individuals who need to wear prosthetics.

6. Increasingly Cheaper to Use

3D technology is not something that only exists in the playrooms of the rich and powerful. The first few 3D printers released on a commercial basis were too expensive for everyday people to buy. But as the technology inflamed the imagination of the tech crowd and found growing popularity, the resulting increase in demand lowered the price of machines. Prices continue to fall to this day.

7. And Now for 4D Printing

3D printing may be all the rage today, but in the near future it’s going to be eclipsed by the arrival of 4D printers. In case you were wondering, the fourth dimension is time, and 4D printers promise to create 3D models that will be able to change with time. This means 4D printed models will be able to change their properties at different time intervals and assemble or break apart on their own. This is mostly the realm of science fiction right now – but it’s possible it could become reality.

I’ve always wanted to have something 3d printed but I just don’t know enough about it to have something done. I like that you had pointed out that there are multiple forms, ones that print in plastic and others that print in metal which is very unique. The project I’ve had in mind might be perfect for this because I have been wanting a plastic key chain but in a weird shape, I’ll have to find a company that offers a service like this.

no

yep i really want 3d printing but i dont know about it