$7.4 Million Granted To Fund Additive Manufacturing Research From NIST

The U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) has announced the award of two grants totalling $7.4 million to fund research projects that will improve measurement and standards for additive manufacturing. The benefits of additive manufacturing will be producing complex products on-demand and quickly, while creating less waste.

NIST is awarding $5 million to the National Additive Manufacturing Innovation Institute (NAMII) in Youngstown, Ohio, which is operated by the National Center for Defense Manufacturing and Machining, for a three-phase collaborative research effort involving 27 companies, universities and national laboratories. Northern Illinois University in DeKalb, Ill., will receive $2.4 million to develop tools for process control and qualifying parts made with layer-by-layer additive manufacturing processes.

“Improving additive manufacturing is an important part of the administration’s efforts to help U.S. manufacturers by supporting new opportunities to innovate,” said Under Secretary of Commerce for Standards and Technology and NIST Director Patrick Gallagher. “The public-private research partnerships led by NAMII and Northern Illinois University are tackling important measurement science-related barriers that must be overcome before this cutting-edge technology can be more widely used, helping America remain innovative and globally competitive.”

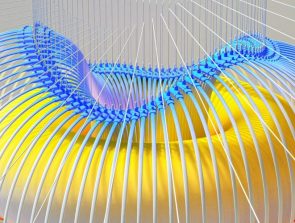

Additive manufacturing, also known as 3D printing, is a group of new technologies that build up objects, usually by laying down many thin layers on top of each other. In contrast, traditional machining creates objects by cutting material away. A diverse array of manufacturing industries—from aircraft to medical devices and from electronics to customized consumer goods—are already using or exploring applications of these new technologies.

Additive manufacturing processes face a variety of hurdles that limit their utility for high-value products and applications. Technical challenges include inadequate data on the properties of materials used, limited process control, lack of standardized tests for qualifying machine performance and limited modeling and design tools. The new projects aim to address those challenges.

Specifically, the grants announced today will support NAMII’s three-part research plan that seeks to ensure that quality parts are produced and certified for use in products made by a variety of industries and their supply chains. Northern Illinois University and its collaborators plan to develop a suite of integrated tools for process control and additive manufacturing part qualification. Descriptions of the two projects can be found at http://manufacturing.gov/msam_awards.html.

The competitively awarded grants, which are for two years, were made through NIST’s Measurement Science for Advanced Manufacturing (MSAM) Cooperative Agreement Program.

As a non-regulatory agency of the U.S. Department of Commerce, NIST promotes U.S. innovation and industrial competitiveness by advancing measurement science, standards and technology in ways that enhance economic security and improve our quality of life. To learn more about NIST, visit www.nist.gov.

About NIST:

Founded in 1901 and now part of the U.S. Department of Commerce, NIST is one of the nation’s oldest physical science laboratories. Congress established the agency to remove a major handicap to U.S. industrial competitiveness at the time—a second-rate measurement infrastructure that lagged behind the capabilities of England, Germany, and other economic rivals. Today, NIST measurements support the smallest of technologies—nanoscale devices so tiny that tens of thousands can fit on the end of a single human hair—to the largest and most complex of human-made creations, from earthquake-resistant skyscrapers to wide-body jetliners to global communication networks. We invite you to explore our web site to learn about our current projects, to find out how you can work with us, or to make use of our products and services.