Build Instructions Released For Jonathan Keep’s Ceramic 3D Printer

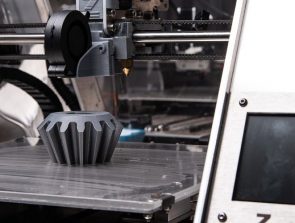

Jonathan Keep has developed his own ceramic 3D printer after he was annoyed and frustrated by 3D Systems buyout and subsequent closing down of production of the RapMan 3D printer. The RapMan was developed by Belgian design studio, Unfold and it was the first kit printer to use clay as a printing material.

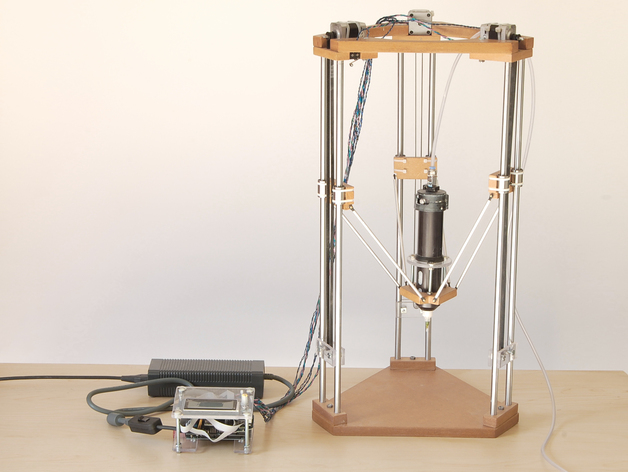

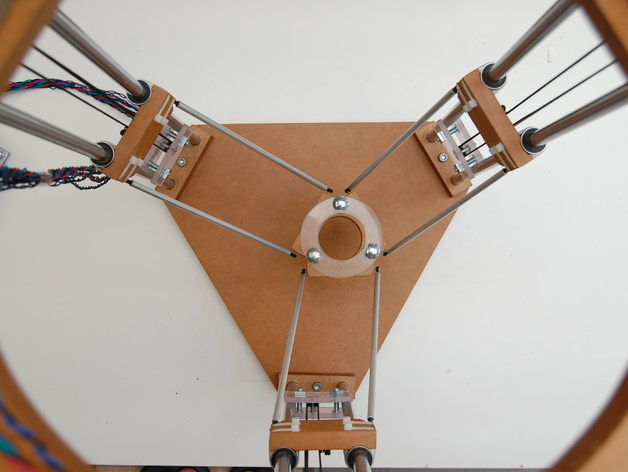

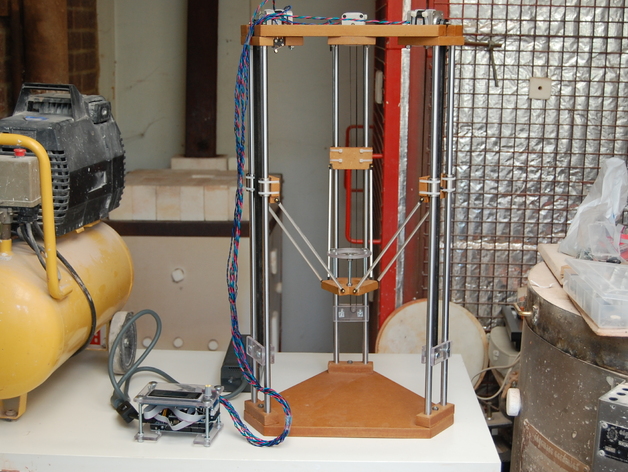

Keep used a Delta type design for his 3D printer. He said “my aim has been to use parts that can either be made with basic DIY tools and skills, or ordered off the internet. The design is specifically for printing in clay but could be adapted to work with other materials. Many other self build 3D printers use parts printed in plastic but with this project I did not want to be reliant on already having access to a 3D printer.”

According to Keep the information on his website is not blue print’s for the printer, but rather a documentation of the design of it. “My experience is as an artist and not as an engineer or computer specialist so I am sure there are many improvements that could be made,” he said. Keep also welcomes others to improve his design but doesn’t want the project to be used for commercial gain.

The printer itself is based on a bootstrap delta style 3D printer which is ideal for printing in clay. Keep used Microsoft Word and A4 paper for the cutting templates for different parts of the printer, but he admits that they aren’t very accurate.

Marlin firmware created by Johann Rocholl was used for the Keep’s clay printer and he used Blender to create and edit the 3D files. For printing and slicing the .stl files Keep used Repetier Host.

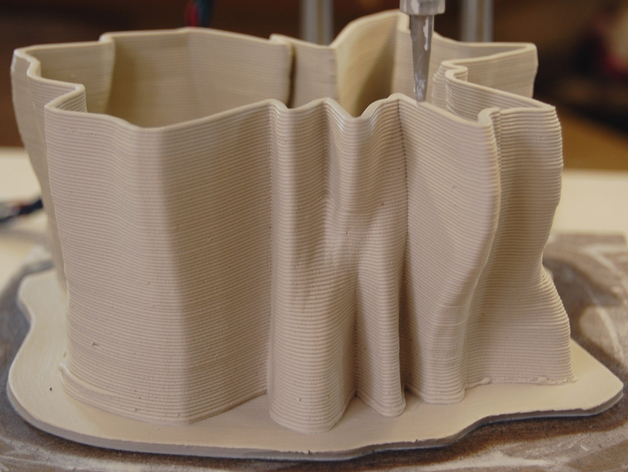

Apparently the clay extruder is adapted from parts form the adhesives industry. Keep used parts from Techcon Systems TS Series dispensing gun. Some of the parts included cartridges, the retainer and the cap but not the gun grip. Compressed air at 30 psi is used to extrude the clay from the cartridge at around 1mm per second. The 237ml cartridge lasts about an hour before a replacement is needed.

Check out the video below and head over to Keep’s website for a full bill of materials.