How Does 3D Printing Work?

Many may have thought that smartphones and their mobile applications are the one thing that had the most profound impact in the world today. Maybe, but what is more disruptive is the latest round of 3d printers being offered by the likes of 3D Systems and Stratasys companies. So why is it that disruptive? The question you should be asking yourself is: “How does 3D printing work?” Without going into too much technical details, let me show you.

A bit of history

Back in the mid-1980s when Chuck Hull invented the world’s first working 3d printer, it was widely considered the domain of science fiction. People had indicated that it will remain expensive and unnatural to produce for another 30 years. And indeed. Now, the main barriers are starting to be overthrown and 3D printing is becoming a feasible manufactering method for a wide array of products. Equipment is more affordable and applications are more widely available.

From design to 3d object

So before we go down to the big scale involved with this new technology, let’s discuss some important details first. Technically, how does 3d printing work? With the use of the Stereolithography process, you transform your creative idea into a digital design – either with the use of Autodesk software or any computer aided design application. Common methodology being applied for this are selective laser melting (SLM) and Stereolithography (SLA). Molding can be better attained with the use of the polylactic acid (PLA) or ABS plastic filament. Then, convert the design into the STL file format which the 3d printer can process. Viola, you now have your own 3d object.

For home use

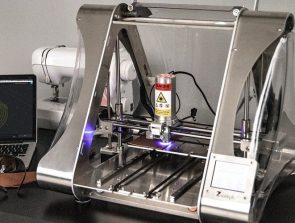

Then, how does 3d printing work for home users? Usually if a person wants some items, he purchases it from a shopping mall or hardware store. With the advent of 3d printing, he can buy the equipment and produce any household item that he needs at a cheaper cost, especially now that the machine and its ingredients have gone low as compared some few years back. You can customize the design, the color and size as long as it will fit your creativity.

Rapid prototyping

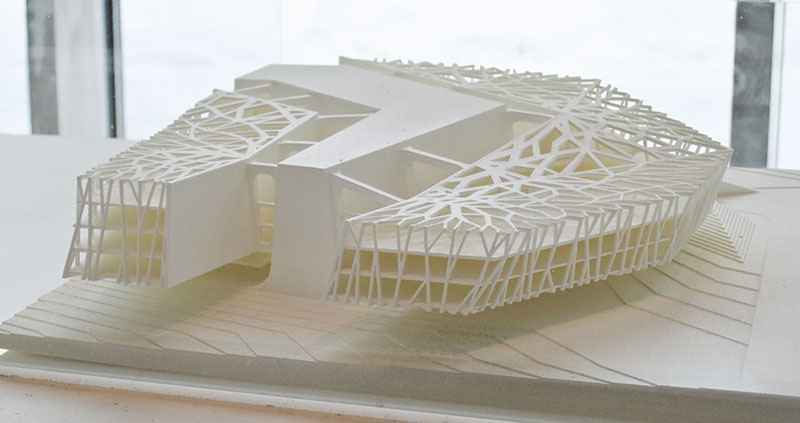

For companies making commercial applications, 3d printing is most valued for cutting down development costs. These days, you don’t have to wait long just to produce your prototype. From minutes to a few hours, 3d printers can make anything. Be it a futuristic car design or an architectural layout for a new commercial tower, this is now the best time to recreate things in a three-dimensional image. Whether you use proprietary or open source design, it’s your output that counts more.

Applications

There are quite a number of industries that will be greatly affected by this disruption. Military gadgets, medical researches, automotive design, wearable products and many more will definitely benefit from transforming creative ideas into the new world in 3d image.