Mark Forged Unveils Carbon Fiber 3D Printer At SolidWorks World

SolidWorks World has already hosted Stratasys’ big announcement, but a relatively unknown company looks set to steal some of the 3D printing giant’s limelight. Mark Forged, is the mysterious company behind the new 3D printer that looks like one of 3D printing’s most exciting products.

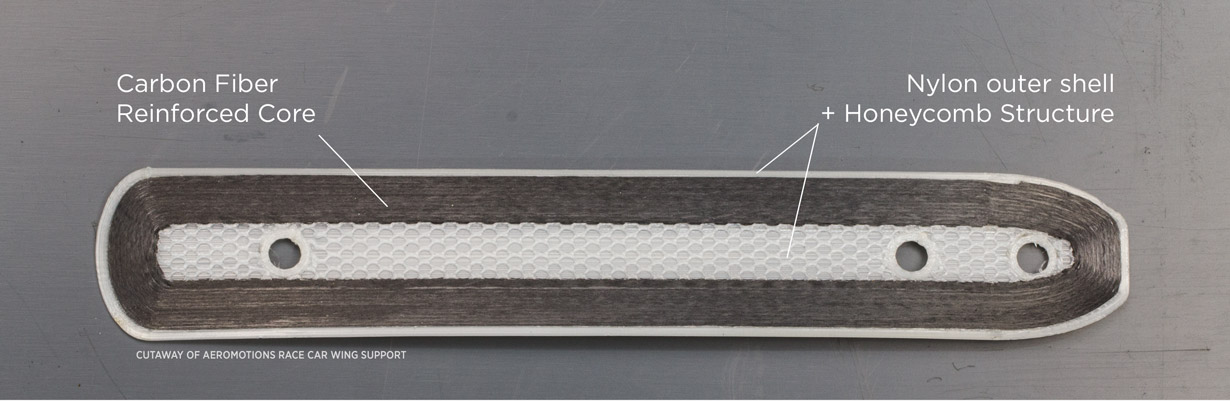

Current 3D printers are plagued by the lack of material choice, we’re either limited to ABS or PLA filaments traditionally. The Mark One from Mark Forged distances itself from conventional 3D printers by using carbon fiber as its material of choice. Using a process called Continuous Filament Fabrication, parts created by the Mark One are encased in nylon and filled with carbon fiber. Two different filaments feed two extruder heads to create the carbon fiber/ Nylon prints, which is up to 20x stiffer and 5x stronger than ABS.

Greogory Mark, the president of Mark Forged is also the co-owner of Aeromotions, a company which specializes in carbon fiber wings, spoilers and body panels for racing cars. Carbon fiber is five times stronger than steel, yet weighs around two-thirds the weight, an important advantage when it comes to high performance applications. Creating carbon fiber components is a tricky process and it typically has to be layered in sheets, and then molded in to the correct shape. Watch the video below of Christian Von Koenigsegg explaining how they create carbon fiber components for Koenigsegg supercars.

Due to carbon fiber’s manufacturing difficulties, Mark decided to create the Mark One to simplify carbon fiber part production. Apart from carbon fiber and nylon, the Mark One can utilize fiberglass and PLA. It features an anodized aluminum unibody, a translucent printing bed and a Kinematic coupling system levels the print bed. The printer itself is compact and elegant looking, measuring 22.6 x 14.2 x 12.7 in (574 x 361 x 323mm), with a print resolution of 100 microns for standard materials such as PLA and 200 microns for materials that use Continuous Filament Fabrication.

“We took the idea of 3D printing, that process of laying things down strand by strand, and we used it as a manufacturing process to make composite parts,” Mark told Popular Mechanics. “We say it’s like regular 3D printers do the form. We do form and function. Composite Filament Fabrication allows you to 3D print parts that are stronger than CNC machined aluminum by weight.”

http://www.youtube.com/watch?v=lnxyXiA8MbY

The printer could also be used for prosthetic’s, “There are a bunch of people who are interested in the prosthetics side,” he says. “There’s a whole fit component. It has to fit on your body. That’s something that’s more art than science, you want to print out a whole bunch of different versions and test them out But then when you have your final version, you want to make exactly that, but really strong.”

While we’ve already seen carbon fiber reinforced filaments, Mark Forged’s Mark One appears to be the first fully functioning 3D printer on the market intended for carbon fiber. It is set to be released in February at a price of $5,000. Find out more here.