3D Printer Auto Leveling – How Important Is It?

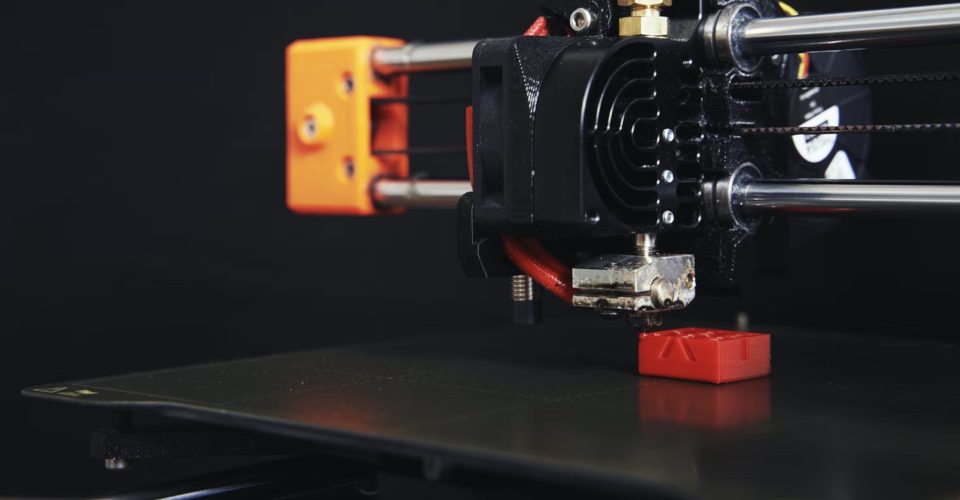

Out of the myriad solutions that are proposed for the huge number of common 3D printing problems, the advice of leveling your bed will almost always be mentioned. As many people who are into 3D printing know, the key to a good 3D print is a perfect first layer. It is just logical that a properly leveled bed is a key component to getting that good first layer.

The next question now is – how should the bed be leveled? Is the manual method good enough, or should you always defer to an automatic bed leveling (ABL) feature? Should you even consider getting a 3D printer that does not have ABL?

ABL vs. Manual – the pros and cons

The methods of ABL are very different from that of the manual method. Most 3D printers should have a provision for manual bed level movement through a set of adjustment screws. When this method is done, the print bed is physically moved so that it maintains a set distance from the nozzle at different points.

An ABL method is different in that it does not physically move the bed. Instead, a probe moves around the print bed to take distance measurements. The firmware then makes adjustments based on these measurements by changing the Z settings of the print head as necessary. An ABL method can be described as being more dynamic and able to adjust to minute deviations on the surface of the print bed.

Precision

Bed leveling isn’t a one-time thing – you will have to do it periodically if you want all your 3D prints to come out well. Considering that, you’re bound to get more consistent results with ABL than you would with the manual method. Relying on a pre-programmed leveling algorithm is simply more reliable than sticking a piece of paper between your nozzle and print bed. A sensor can also more readily detect very small deviations on your print bed surface.

Speed

As the name implies, ABL methods run automatically with minimal user intervention. You can run ABL on your 3D printer while you fiddle with your filament or make last-minute preparations. In contrast, you will have to dedicate a few minutes to do a manual bed leveling yourself. There is no contest when it comes to time – ABL wins this hands-down.

Complexity

An argument can be made that manual bed leveling is the simpler option of the two. You just have to do it once to understand how it works, then it becomes a standard routine task. ABL may be an automatic method, but you will need to set it up in your printer’s firmware. This can take a lot of extra work, especially if you’re installing a third-party ABL sensor on your printer. If the technical know-how is beyond your current skill level, you will have to put a lot of effort into setting up an ABL feature.

Cost

Whether you’re buying a third-party ABL sensor or a 3D printer with built-in ABL, you will inevitably be spending about $20 to $80 more. Leveling your bed manually costs almost nothing.

How does auto bed leveling work?

As with any automated process, ABL depends on a pre-set algorithm to make its adjustments. There are different ways of implementing ABL, but they all fall into either of two categories:

Mesh leveling

As the name implies, mesh bed leveling involves the printer dividing the print bed into a mesh via evenly spaced grid lines. The height of each grid square is then measured so that deviations can be compensated for. An ABL feature based on a mesh-based method can account for warped sections of a print bed, a common condition in heavily used 3D printers.

Some printers can also use a mesh-based leveling algorithm for a hybrid manual-auto bed leveling technique. The printer probe takes height measurements based on a pre-defined grid and instructs the user on how the print bed height should be adjusted. This works fairly well, especially if you prefer to make actual, physical bed height adjustments.

Matrix leveling

In a matrix-based leveling method, the printer takes measurements at several different points and generates a singular plane based on these measurements. If a tilted plane is detected, the printer compensates by rotating the coordinate axes. This method is best for compensating for tilted print beds. However, you may not get the best results out of it when the bed has been warped.

The objective of a matrix-based leveling method is to adjust the height of the printhead so that the print is perpendicular to the print bed, even if it is tilted. This might mean that the print may not necessarily be aligned to the printer’s Z-axis. Printing on a tilted bed may be problematic if your model has a lot of overhang features.

ABL processes

Now that we understand mesh and matrix-based ABL algorithms, we can see how they are applied to the different methods of ABL that 3D printers implement. The selection may vary based on the 3D printer but these are the most common options available:

3-point leveling

In 3-point leveling, the probe takes measurements at precisely three points of the print bed. These three points are then used to generate a singular plane. The coordinate axes are then rotated to compensate if a tilted print bed is detected. The 3-point leveling method is a classic application of the matrix-based leveling algorithm. It is a quick and simple process, but cannot compensate for warped beds.

Linear

The linear leveling method is quite similar to the 3-point method in that it also generates a single plane that may be tilted in any direction. However, the linear technique has better accuracy on account of a higher number of probe measurements.

In this method, measurements are made at several points according to a pre-defined grid. With more points, the generated plane better represents the actual orientation of the print bed. Similar to other matrix-based methods, the coordinate axes are then rotated to compensate for any tilt.

Bilinear

The measurement step of the bilinear method is almost exactly like that of the linear method – the probe measures the height of the print bed at several points according to a pre-defined grid. However, the bilinear method uses this data to construct a mesh represented by the different data points. This is not necessarily a single plane.

This mesh-based method is an excellent ABL technique for warped print beds. This has made the bilinear method one of the most popular and widely used techniques for ABL, especially in more modern 3D printers.

Which 3D printers have ABL?

The easiest way to use ABL is to get a 3D printer that already has a built-in ABL feature. These are usually a bit more expensive, so expect to spend $400 or more. Although there are now a lot of 3D printers that fall under this category, they are not all made equally. Here are some of our recommendations for 3D printers with ABL:

Other options for upgrading to ABL

If you already own a 3D printer that does not have ABL, you can easily upgrade it with an ABL sensor kit. You can also save money by buying a 3D printer that does not have ABL and just doing the upgrade yourself. You will still end up spending less even with the combined cost of the 3D printer and ABL sensor.

One of the most popular 3D printers with no ABL feature is the Creality Ender 3. This is a relatively inexpensive 3D printer that you can get for less than $200. There is a whole list of ABL sensors that are compatible with the Ender 3, but the best option would be to get the official Creality Ender CR ABL Sensor Kit. This kit is compatible with the Ender 3, 3V2, 3S, 3Pro, and 3-Max.

Conversely, there are more “generic” ABL kits such as the ANTCLABS BLTouch sensor. This is a more versatile kit that should be compatible with most 3D printer brands. It works with the Ender 3 and the CR-10, among a huge list of other 3D printers.

Is ABL necessary for 3D printing?

If your printer doesn’t have an ABL feature, should you be saving up for an upgrade? Do the benefits of ABL justify the additional cost and the skill needed to set it up?

Without a doubt, an ABL feature can be considered “nice to have.” However, 3D printers can work perfectly fine even without it. Manual bed leveling suffices for most applications and is a necessary practice, even for 3D printers that do not have ABL. Prints beds can tilt over time and repeated use and even the best ABL algorithm cannot make up for a severely tilted print bed.

The biggest value of ABL is as a time-saver. If you print a high volume of orders for commercial reasons, then being able to level your bed with a single-button ABL feature saves a lot of time and effort over the long run. This value is not as pronounced for those who only 3D print as a hobby.

Final thoughts

As many of the newer 3D printers come out with ABL features, those who are using the more basic, manual bed leveling methods may feel left out. An ABL feature is nice and may save some time, but it’s not absolutely necessary. The old-fashioned manual bed leveling technique is still useful in any situation.

For those using ABL, an understanding of how ABL works could prove to be valuable knowledge. The effectiveness of ABL techniques may vary based on different scenarios. A badly warped or tilted bed may be beyond what ABL can compensate for.