Cleaning Filament for 3D Printers – What It Is and How to Use It

We all love our 3D printers when they are working perfectly. Sometimes, the stars align just right, and you come back to a perfectly made 3D print after leaving it for almost an entire day. However, 3D printing users know that getting to this point can be a long and frustrating process.

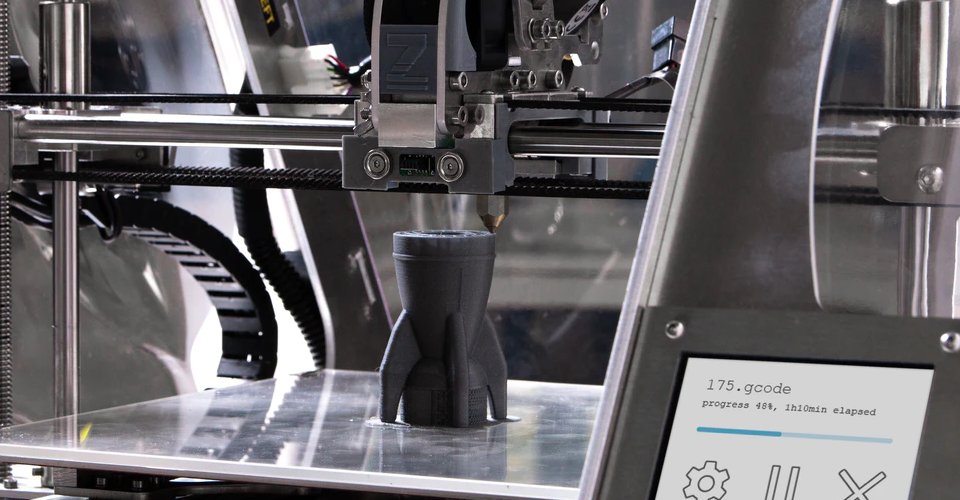

Maintaining a 3D printer in tip-top shape involves constant calibration, trial and error, and cleaning. One of the most soiled parts of a 3D printer is its nozzle and extruder assembly. In this article, we take a look at a type of filament that is designed specifically for cleaning your 3D printer.

What is cleaning filament?

As the name implies, cleaning filament is a special filament designed solely for cleaning a 3D printer nozzle. When used correctly, cleaning filament should remove any residual filaments in your nozzle that may have come from your previous printing jobs.

At first glance, cleaning filament may look just like Nylon. Incidentally, Nylon is the filament of choice for doing the old-fashioned “cold pull” method for cleaning nozzles. Cleaning filament is a bit more custom-made for this particular application. While the exact material used in cleaning filament is not disclosed, it is the same non-abrasive compound used for removing chemical residues in equipment used for injection molding of plastics.

Cleaning filament is sold in small coils and is significantly more expensive per unit weight compared to standard 3D printing filaments. However, you will not need a large volume of this filament – just a few feet per cleaning session will do.

Is it better to use cleaning filament over other cleaning methods?

There are a couple of recommended methods for cleaning a nozzle that has been partially or completely clogged with filament residue. One of the most popular is the “cold pull” method. This involves inserting a piece of Nylon filament into the nozzle, heating it up to around the printing temperature of Nylon, letting it cool, and yanking it out forcefully.

The problem with the “cold pull” method is that it takes a lot of time. You will likely have to do the entire process at least three times before you can be sure that your nozzle is unclogged. It’s also a very rough method. Pulling the filament out forcefully does not feel comfortable, considering how delicately we tend to treat the parts of our 3D printer.

When the cold pull method fails, the next best option would be to fish around the nozzle with a hypodermic needle or a drill bit. This isn’t very reliable and can also damage internal components in your nozzle.

The best thing about using a cleaning filament is that it’s a relatively quick process. Just run the filament for a few seconds or until no visible residue is extruded with the filament. It avoids the mechanical stress of having to yank out a filament or fish around for residue with sharp tools.

Running a small segment of cleaning filament is also a good idea if you’re switching from one filament to another. This makes sure that your new print will not have impurities from your previous project. This option is particularly handy when switching between vastly different colors of filament.

A limitation of cleaning filament is that it can only be used as long as you can still extrude filament through your nozzle. If your nozzle has been completely blocked, then no amount of cleaning filament can help you. With this in mind, it’s best to use cleaning filament as a preventive measure. Do not wait until you can no longer print before you think about cleaning your 3D printer nozzle.

How to use cleaning filament

If your printer has a Bowden extruder, then the first step would be to disconnect the Bowden tube. This means that you will have to feed the filament manually. Direct extruder printers are a bit simpler as you can just feed the filament automatically.

The best temperature for extruding the cleaning filament is just above the printing temperature of the filament you last worked with. Do not be tempted to turn up the temperature to the maximum that the cleaning filament can withstand. Doing so risks burning the filament residue in the nozzle and will make them even more difficult to remove.

Right after running the printer, you should see some of the leftover filament being extruded from the nozzle. This should be followed by the cleaning filament. In most scenarios, the cleaning filament will have specks of residue material. Continue doing this until the cleaning filament comes out clean of any residue.

The whole process typically takes less than a minute and should consume less than 12 inches of the cleaning filament.

Where to buy cleaning filament for 3D printers

There are not many brands that carry cleaning filament, likely because they are not very popular. We have only come up with two fairly reliable options.

1. eSun 3D Printer Cleaning Filament

This filament from eSun is, by far, the most popular cleaning filament in the 3D printing community. With an effective temperature range of 150 to 260 C, the eSun cleaning filament can work with PLA and high-temperature filaments like Nylon and PC.

Many users have had a very good experience in using the eSun cleaning filament. It may seem quite expensive at more than $10 for a 100-gram coil, but you will really only need a few inches of the filament per run. We suggest trying it out as it’s still very affordable.

2. Inland 3D Printer Cleaning Filament

The Inland cleaning filament costs about as much as the eSun version but is less popular. The temperature range is also similar at 160 to 260 C, making it suitable for removing stubborn residue from high-temperature 3D printing.

Although this filament does not have as much feedback as that of the eSun cleaning filament, it is similarly well-reviewed. This heat-stable material is not abrasive, has good adhesive ability, and is marketed as being ‘eco-friendly.’

3. NOVAMAKER 3D Printer Cleaning Filament

Another fairly popular choice is this cleaning filament from the NOVAMAKER brand. Just like the other brands, this filament prints at any temperature between 150 to 260 C. It is described as having high viscosity and good heat stability.

According to product instructions, this filament can either be used hot or in “cold pull” methods. It has been described as having a foaming response to heating, which presumably enhances its cleaning capabilities. It’s difficult to judge exactly how well this filament performs. However, the filament is very cheap so it would not hurt to try it out.

Final thoughts

If you own a 3D printer, doing regular preventive maintenance is the best thing you can do to avoid problems. Nozzle cleaning is one of the more important maintenance activities. Although cleaning with a filament is not considered standard practice, many users have been getting good results from doing it regularly or every time they change filament types.

It’s quite noticeable that the cleaning filaments in the market today do not exactly come from the more well-known 3D filament brands. Don’t let this discourage you. Cleaning filaments are very cheap and easy to use. They are worth a try and might even become a new habit for you.