How a 3D Printer with Dynamic Platform Can Reduce Filament Usage

Support structures are commonly perceived as a “necessary evil” in 3D printing. They can use up a significant volume of filament but are often needed in highly complex 3D models. There are ways to reduce the use of support material but it is almost impossible to avoid them completely.

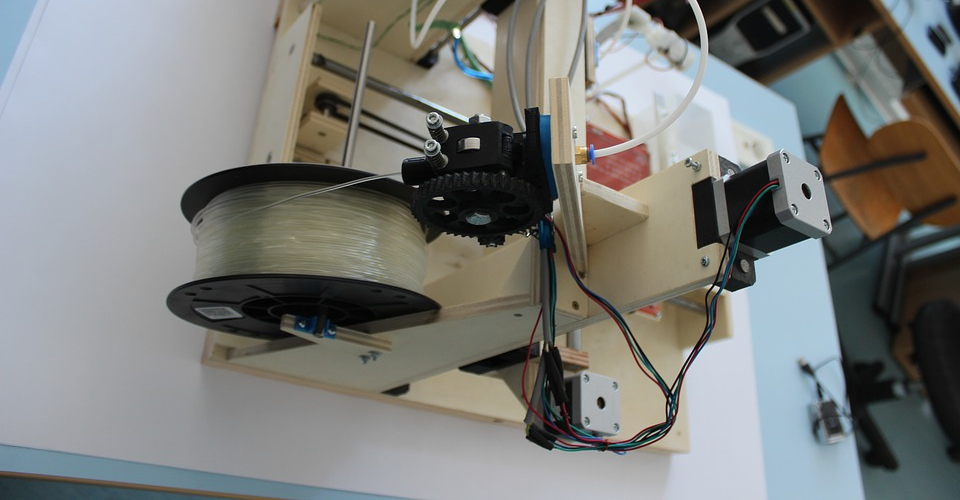

A new 3D printer being developed by researchers at the University of Southern California aims to reduce filament usage for support structures. The premise behind this new printer seems simple but still impressive – dynamic platforms. What are these dynamic platforms and how do they work?

How do the dynamic platforms work?

The printer designed and developed by a team in the Department of Industrial and Systems of Engineering of the USC aims to reduce filament use via a dynamic platform. Instead of a single piece of material, the platform is made of an array of movable pins. These pins can rise as necessary to reduce the amount of filament needed to support a model as it prints.

Before arriving at the final design, the printer had to go through a few revisions. An earlier version needed separate motors for each moving metal pin, making it impractically expensive and power-intensive. The current version only had one motor to move around a platform to raise groups of metal pins.

Work on this 3D printer has been led by Professor Yong Chen and Ph.D. student Yang Xu. A paper on the design has been published in the Additive Manufacturing journal.

Potential time and filament savings

Chen said that he worked primarily with biomedical doctors who used 3D printers for creating tissues or organs using biomaterials. The material used in this scenario is a lot more expensive than your typical 3D printing application. This dilemma provided the motivation for designing and creating the innovative 3D printer.

According to the study, using the dynamic platform can result in savings of up to 35% in material usage. Obviously, this 35% reduction is a lot more valuable in biomedical applications. Still, there is room for this technology even in casual FDM 3D printing.

One also must not understate the potential reduction that this technology can provide in solid waste. As 3D printing becomes more popular, there will inevitably be more waste from misprints, support structures, broken filament, rafts, and brims. If this technology can become more common, it should substantially reduce the need for support materials and the corresponding plastic waste.

Chen also states that using the dynamic platform can reduce printing time by up to 40%. This is huge, considering how a single 3D printing job can take upwards of 12 hours. This is going to be a more significant benefit in the context of commercial 3D printing applications with large volume requirements.

Will this printer become commercially available?

According to the press release, the team had already applied for a patent for the dynamic platform technology. There are currently no plans to reproduce the 3D printer at a mass scale.

The team envisions applying the technology for large-scale additive manufacturing, citing examples of the automotive and aerospace industries. 3D printing a project at this scale, such as a piece of furniture or the body of a car, can take an entire day to finish. Using a dynamic platform can reduce the use of valuable material and reduce total printing time.

It may be unlikely to see this type of 3D printing technology in desktop FDM printers. A piece of technology this novel would be too expensive for this market. However, we would not say that it’s completely outside the realm of possibility. History has already surprised us too many times by how seemingly inaccessible technology becomes incredibly common.

Final thoughts

The amount of 3D printing material that goes into support structures is something that we have always have to deal with. It’s possible to reorient a model or integrate structures into a design, but it’s likely that you will still have to use supports anyway.

The innovative research project on dynamic platforms may provide a new paradigm for 3D printing. There will likely be a higher degree of design freedom when one no longer needs to worry as much about 3D printing support structures. We are eager to see where this technology will go.