How Often Should You Change Your 3D Printer Nozzle?

The frequency of swapping out nozzles depends on how heavily you use your 3D printer. The use of more abrasive filaments can also wear down the hot end nozzle faster. You can consider using hardened steel or ruby-tipped nozzles that last longer but are also significantly more expensive than the standard brass nozzles. A new nozzle may also be necessary if the old one gets damaged or severely clogged.

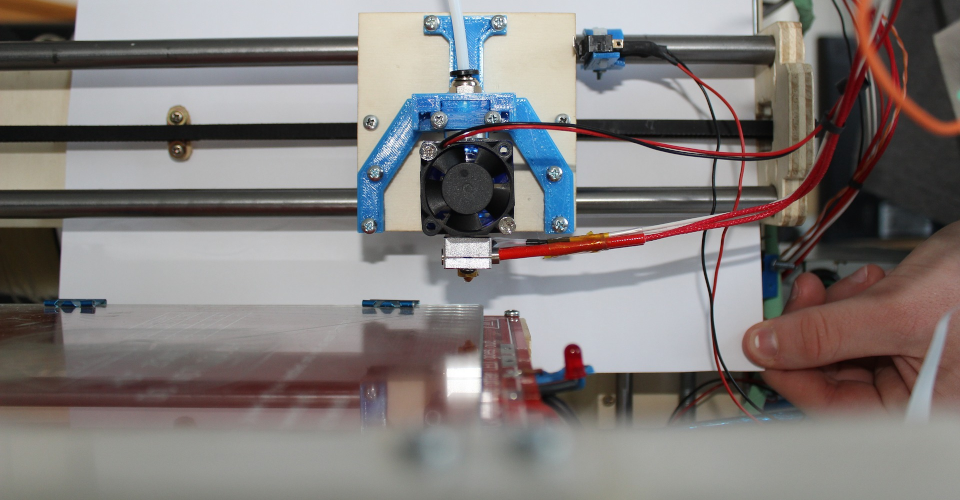

In terms of its effects on print quality, the nozzle can be considered one of the most important parts of your 3D printer. How can you tell if your old nozzle needs to be replaced?

Signs of damage

The most obvious reason to replace your nozzle is when it gets damaged. Damage can take many forms – from warping of the metal to the nozzle opening getting worn out. In any case, nozzle damage will have serious consequences in terms of detail accuracy and overall print quality.

To better help you assess if a nozzle has been damaged beyond being useful, here are the most common mechanisms of nozzle damage:

Abrasion of the nozzle opening

The most common mechanism of damage to nozzles is abrasion. This happens when an abrasive filament passes through the nozzle opening, very slightly wearing down on the material of the nozzle. Over time, this causes the opening to become wider. This will eventually result in loss of detail resolution and lower visual quality of your 3D prints.

There are some filaments that are more likely to cause nozzle abrasion. The most common culprits are composite filaments or filaments that contain solid particles such as wood, metal, marble, or carbon fiber in a plastic matrix. Should you wish to print with composite filaments, it is best to swap out a brass nozzle for a hardened steel or stainless steel replacement.

Printing too close to the bed

Though far less likely to happen, you can also damage your nozzle when your initial z-setting puts it too close to the print bed. This can also happen because of an improperly leveled bed.

When this happens, the consequences are two-fold. Not only can it cause your nozzle to get bent or scratched, but you will almost certainly also cause an abrasion of the print bed. You will then have to replace both the print bed and the nozzle.

Tool damage

One thing you need to keep in mind is that metals, particularly brass, become very soft when heated. Whenever you need to manipulate a heated nozzle with any tool, there is a chance that you can cause damage to the nozzle. Be very careful when cleaning or removing a nozzle that is still at a very high temperature.

If you can see signs of damage in your nozzle via visual inspection, then the damage is certainly serious enough to warrant a replacement. It also helps to have a brand new nozzle on hand to compare your current nozzle to, as some signs of damage may be too subtle.

Heavily clogged nozzles

Nozzle clogging is something that you will need to deal with eventually, no matter how careful you are. Leftover filament, dust, or oils can burn in the hot end and deposit in the nozzle. These residues can typically be removed via the cold pull method or soaking in acetone.

Removal of nozzle residue is generally easy as long as you do it regularly. If any residue continues to burn, they tend to form brittle and abrasive carbon deposits. This will inevitably cause inconsistent extrusion and become harder to more they burn.

Even if they do get removed, carbon deposits become hard enough to cause internal abrasion in the nozzle. Any scratches on the inner surface of a nozzle can make it easier for more deposits to form, thereby accelerating the process of clog formation.

If you notice your nozzle getting clogged more frequently than usual, then you may want to consider doing a nozzle replacement. You can also try removing the nozzle and doing a visual inspection of its inner chamber.

Should you use a steel nozzle?

A common piece of advice in 3D printing communities is to use a hardened steel nozzle in place of a brass nozzle so that you won’t need to replace them as frequently. There is certainly some wisdom in this – brass is a relatively soft metal that can be worn out or deformed a lot easier.

This does not mean that a brass nozzle is automatically the inferior option. Brass has better thermal conductivity, so it heats up faster and more evenly. It is also extremely cheap – you can buy a pack of 20 brass nozzles for less than $10. They are so cheap that replacing a brass nozzle after just a few days’ worth of use is considered a good return on investment.

In contrast, hardened steel nozzles cost about $2 apiece. They still are not expensive, but are at a price that will give you pause about replacing them haphazardly. Hardened steel is also not as conductive as brass, so you may need to pre-heat the hot end for longer before starting 3D printing.

An ideal scenario is having both brass and hardened steel nozzles. Brass nozzles work perfectly fine with filaments like PLA, ABS, and PETG. These are non-abrasive filaments. As long as the nozzle is not damaged because of tools or contact with the print bed, a brass nozzle will last for a very long time.

However, having a stock of hardened steel nozzles is also preferable when you wish to print with more abrasive filaments. Steel is quite hardy against wood or even other metal particles. Printing with composite filaments is a great way to expand your range of skills in 3D printing.

Final thoughts

We find that brass nozzles tend to get judged too harshly as being too easily damaged. The truth is that brass nozzles can last for a very long time if you treat them properly. Don’t handle them too harshly and certainly don’t try to extrude abrasive filaments through them.

Regardless of which type of nozzle you use, nozzle replacement is something that you will have to do eventually. For this reason, it is always a good idea to have spare brand-new nozzles in your workshop.