What Size Should the Nozzle of Your 3D Printer Be?

While most 3D printers ship fully assembled or with all the necessary components, that’s no reason to limit yourself to the default parts. Having more alternative components gives you a bit of added flexibility when working with different filaments, or if you’re looking for different results out of your finished prints.

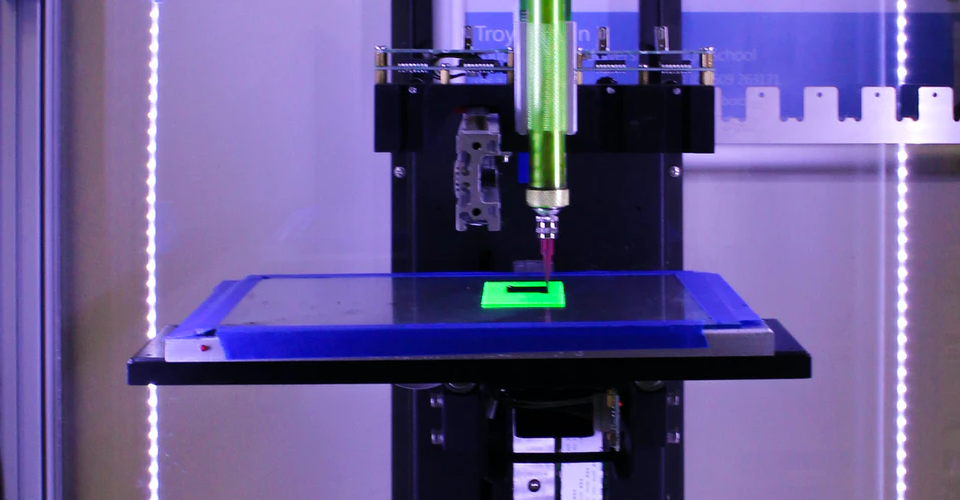

The extruder nozzle is one part of a 3D printer that’s fairly easy to replace. However, switching from one nozzle to another can have pronounced effects on the performance of the printer and the quality of the product. If you’re still confused about what size of nozzle you should use, then we’ve prepared this guide especially for you.

Factors to consider when choosing a nozzle diameter

Most 3D printers will come with a brass nozzle with a diameter of 0.4 millimeters. This nozzle is perfectly fine and will produce satisfactory results under most conditions. However, learning how to replace your 3D printer’s nozzle opens up new ways of customizing the appearance and quality of your finished products.

Layer height

The layer height of a 3D printing project is often set as a fraction of the diameter of the nozzle. The slight compression that this creates allows for better layer-to-layer adhesion and also enhances the level of details in the vertical plane. As a rule of thumb, setting the layer height to about 80% of the nozzle diameter works well in almost all circumstances.

If your design has a lot of curved surfaces, the ability to set thinner layers also means that they can take on a more curved appearance rather than layers simply stacked on top of each other. For professional applications, thinner layers also mean that there is less work needed to polish the surfaces, as the layer lines are less pronounced.

Wall thickness

The wall thickness of any 3D printing project is also determined by the diameter of the nozzle. In contrast to layer height, the wall thickness is set as a multiple of the nozzle diameter, instead of a fraction. In most instances, a wall thickness that is twice the nozzle diameter is good enough for standard 3D printed projects. For more heavy-duty applications, this can be scaled up to three or four times.

While the overall thickness of the wall can be increased infinitely, the advantage of a smaller nozzle is that it allows for more granular adjustment of the wall thickness settings. This is particularly important if you have specific dimensions in mind for your finished product.

A smaller nozzle also allows for finer details on the horizontal plane, or in the plane parallel to the print bed. For instance, any text on the top surface of the model can be recreated more legibly if you’re working with a smaller nozzle.

Printing time

When it comes to choosing between different nozzle sizes, it often comes down to a compromise between the level of detail and printing time. While smaller nozzles are excellent for recreating very fine details, larger nozzles can vastly reduce the printing time for any given model.

Keep in mind that the layer height settings play the biggest role in determining the printing time. To realize this advantage of a wider nozzle, you will have to increase the layer height, thus reducing the number of times that the nozzle needs to travel around the perimeter of the model. With some tweaks, you can achieve a total printing time that is three to four times shorter than if you had used a standard 0.4-millimeter nozzle.

Toughness and impact-resistance

Layer lines are an inherent feature of anything 3D printed using FDM technology. These highly visible lines are the boundaries between separate layers. Aside from being characteristically unsightly, these layer lines also create weak points in any 3D printed project. Indeed, any 3D printed project typically fails somewhere along these layer lines.

Another important advantage of printing with wider nozzles and thicker layers is that it greatly reduces the number of layer lines in any given model. This reduction in weak points makes the product a long stronger and resistant to failure due to stress or impact. For instance, a model printed using a 0.6-millimeter nozzle can withstand 25% higher energy compared to the same model printed with a 0.4-millimeter nozzle.

Optical properties

3D printing an object that is supposed to be as clear as glass is particularly challenging. Not only should you use a high-quality clear filament that is free of contaminants, but you also need to tweak your printer settings to maintain transparency. For reference, transparency is attained by making sure that light can pass through a material with minimal internal reflections.

The challenge with FDM printing is that the layer lines themselves can promote internal reflections, especially if there is poor layer-to-layer adhesion. There are several measures to address this, such as increasing the print temperature and increasing the extrusion rate. Using a wider nozzle is also beneficial, as it allows for a reduction of layer lines.

Removal of supports

We’ve already gone over how a wider nozzle supports increased strength. While this is desirable for the actual project, it’s a huge disadvantage when it comes to supports. Support structures need to be just strong enough to prevent overhanging features from collapsing, but not too strong that they can be difficult to remove. If you’re printing a huge model with a wide-diameter nozzle and you need to have support structures, better be ready with your pliers and other cutting tools – it’s going to take a bit of work.

Abrasive filament types

Composite filaments refer to filaments that contain solid particles embedded in a plastic matrix. The point of using composite filaments is to come up with a 3D printed object that does not look like plastic. Instead, they attempt to mimic the appearance of the solid particles integrated into the plastic. Noteworthy examples include wood, metal, and marble fibers.

One of the major issues with working with a composite filament is that the solid particles introduce a lot of abrasion into the 3D printer components. This is most pronounced on the extruder nozzle, as the filament material needs to be heavily compressed as it goes through the nozzle opening.

To avoid issues with abrasion, the easiest solution is to use a wide-diameter nozzle made with abrasion-resistant material.

Which applications are appropriate for different nozzle sizes?

All things considered, the 0.4-millimeter nozzle that comes with most 3D printers hits the perfect balance. It can print models with a reasonable level of detail but does not take an exceedingly long time to finish a project. For most print jobs, the stock nozzle will do perfectly fine.

However, there’s always the option of getting an alternative nozzle that has either a smaller or wider opening. The common options include 0.25 millimeters or 0.60 millimeters, although going as high as 1 millimeter is not unheard of. Some 3D printing firms have been experimenting with nozzles as small as 0.1 millimeters, although you’re not likely to find a nozzle that small being sold commercially.

Before you go through all the work of replacing your 3D printer nozzle, ask yourself first – are you using the right nozzle for the job? Here are some tips for you to answer this question.

Use a 0.25 mm nozzle if….

You don’t mind the extra waiting time

The difference between the level of detail between 0.4-millimeter and 0.25-millimeter nozzles is so small that you’ll need to take a really close look to notice any difference. The difference in printing time is much more apparent. When you switch over to a new nozzle, you could easily end up with a printing time that is almost twice as long as it would have taken with a stock nozzle. If time isn’t an issue, then swapping in a smaller nozzle should not be a problem.

You’re printing miniature figures and custom jewelry

A smaller nozzle truly shines when you’re recreating small models, such as miniature figures. Jewelry is also an excellent sue for nozzles with narrow openings, especially if the reference model has a lot of thin and precise lines. Limiting the use of small nozzles to similarly small projects also deemphasizes any printing time downgrades.

Your models have printed text

Printing small models that come with text can be exceptionally tough for a stock 0.4-millimeter nozzle. This is a job that calls for smaller nozzles, especially if the text is on the top surface of the model.

Use a 0.60 mm nozzle if…

Your model is large and contains no fine details

Vases, plant pots, pencil cases, and decorative bowls are some of the best uses for a nozzle that’s a bit wider than usual. Not only are they larger than the usual stuff that’s made in 3D printers, but their designs are also pretty simple – no need for intricate details or small text. Moreover, printing with a large nozzle gives these products a bit of advantage in terms of mechanical strength.

You want to finish up quickly

Using a wider nozzle and making the corresponding adjustments to layer height can greatly speed up the 3D printing process. This can be very useful, especially if you’re working on large scale projects. If only for this single advantage, keeping an alternative nozzle with a wider opening is already worth it.

Use a 1 mm nozzle if…

You don’t mind the highly visible layer lines

Printing with a 1-millimeter nozzle is highly unusual, so it might be jarring to see what the finished product will look like. The thicker layers may reduce the number of layer lines, but it also means that these layer lines become more visible than ever. This isn’t necessarily a bad thing – you can make this unusual aesthetic work to your advantage. The best thing about it is that you can finish printing projects up to five times faster than if you had done it with a stock nozzle.

You’re trying to make clear 3D prints

An exceptionally wide nozzle is a great tool for printing with a clear filament. Fewer layer lines mean fewer “boundaries” that can promote internal reflection. Being able to print layers thicker than 0.5 millimeters gives you a huge leg up in providing a clear optical path for light to shine through. Just make sure to still print as hot as possible, as you still want those layers to effectively fuse with each other.

Final thoughts

The nozzle is one of the more readily customizable parts of a 3D printer because it’s easily accessible and replacement nozzles aren’t expensive. It’s also a great place to start experimenting if you want to “level up” your 3D printing skills.

More than a means of customizing 3D printers, changing nozzles can prove to be very useful whether you want your prints to have more precise details or you want to cut down on printing time. Swapping out nozzles is a small change that can yield huge benefits.