3D Printer Stringing: 6 Simple Tips to Prevent It

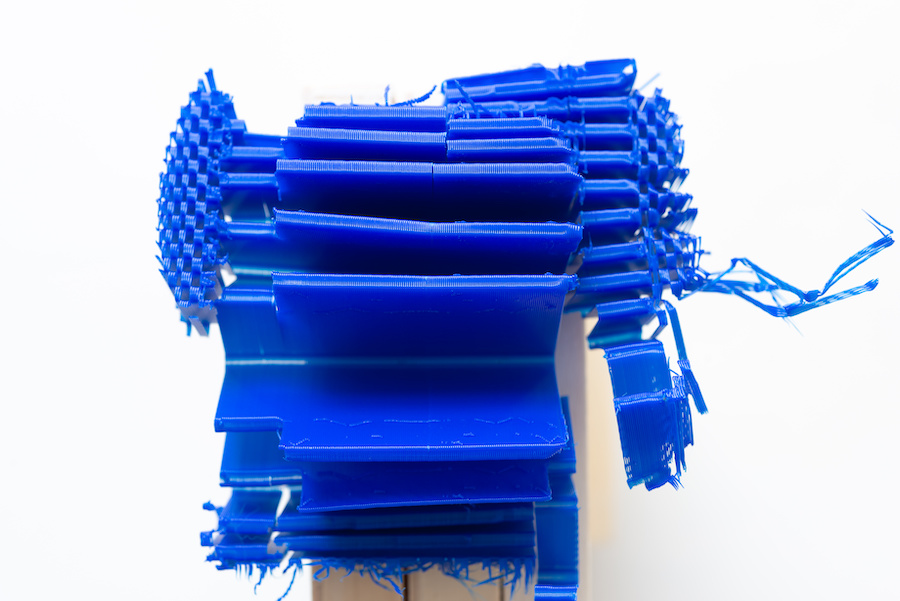

3D printing is an amazing technology that has revolutionized the manufacturing industry. However, one common problem that many 3D printing enthusiasts face is stringing. Stringing occurs when the 3D printer leaves thin strands of filament between different parts of the printed object, resulting in a messy and poor-quality print. In this article, we will discuss some tips on how to prevent 3D printer stringing and achieve a high-quality 3D print.

1. Adjust the Temperature Settings

One of the main causes of stringing is incorrect temperature settings. If the temperature is too high, the filament will become too fluid, resulting in a stringy mess. If the temperature is too low, the filament will not melt properly and will result in poor adhesion. Therefore, it is important to adjust the temperature settings of your 3D printer according to the filament manufacturer’s recommendations.

These are some common ranges, but it’s best to refer to the filament manufacturer’s recommendations:

• ABS Filament: 200-250°C

• PLA Filament: 180-220°C

• Nylon Filament: 220-240°C

• PETG Filament: 225-235°C

• TPU/TPE Filament: 230-250°C

2. Slow Down the Print Speed

Another factor that can lead to stringing is too fast of a print speed. The faster the nozzle moves, the more likely it is to leave behind a stringy trail of filament. To prevent this from happening, try slowing down your 3D printer’s speed settings until you achieve a good balance between speed and quality.

3. Retraction Distance Settings

Retraction is a process in 3D printing where the printer pulls the filament back slightly to prevent oozing and stringing. By enabling retraction settings in your 3D printer, you can reduce the amount of filament that is left between each layer, resulting in a cleaner and smoother print. The retraction settings can usually be found in the slicing software used to prepare the 3D model for printing.

4. Clean the Nozzle Regularly

A clogged nozzle can also lead to stringing. Therefore, it is important to clean the nozzle of your 3D printer regularly to ensure that the filament flows smoothly. There are several ways to clean the nozzle, including using a cleaning filament or a specialized cleaning tool. It is also important to replace the nozzle periodically to ensure that it is functioning properly.

5. Enable Z-Hop

Z-hop is a setting that raises the nozzle slightly during travel moves, which helps prevent the nozzle from catching on previously printed layers and causing stringing. Enabling this setting can help reduce the amount of stringing in your prints. However, be aware that enabling Z-hop can also increase the printing time and may cause other issues such as layer shifting, so it’s important to test it out and adjust the settings as needed.

6. Keep Your Filaments Dry

Another problem people face especially with PLA is that it absorbs water.

Having your filament dry is very important, otherwise the 3D printer won’t be able to properly extrude plastic leading to stringing, poor layer adhesion, and curling.

To keep your filaments dry, it’s best to store them in air-tight containers. These containers should also be stored in an area that is away from any humidity or moisture. This can be done by storing it in a cool, dark area such as a closet or drawer. If you have extra space in the same area, you can also consider using a dehumidifier or silica gel packets placed inside the container to help absorb any extra moisture that might be present.

3D printer stringing can be frustrating, but with the right techniques, it can be easily prevented. By adjusting the temperature settings, using retraction settings, and cleaning the nozzle regularly, you can achieve a high-quality 3D print without any stringy mess. With these tips, you can take your 3D printing game to the next level and create amazing prints that are free from defects.