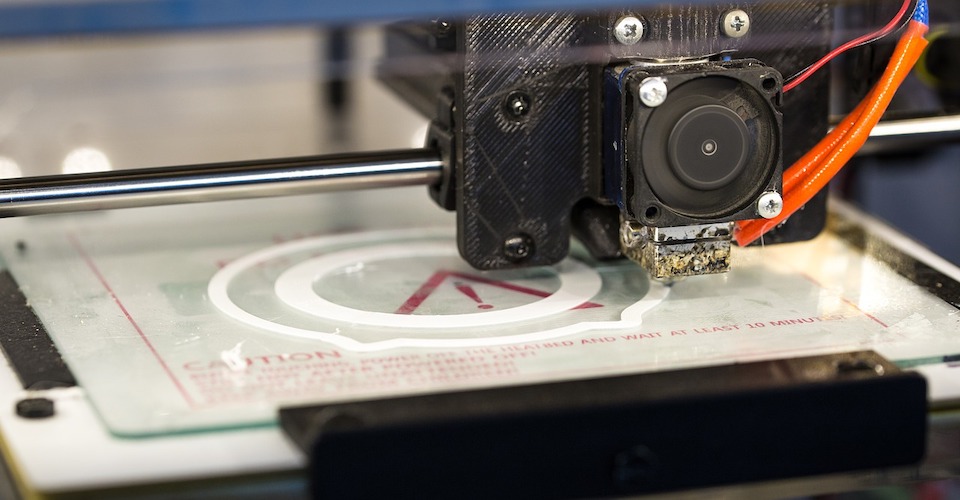

3D Printer Stringing: What Causes it and How to Avoid it

Even the most experienced 3D printing professionals run into problems every now and then. Trying out a new filament, getting a new nozzle, an extruder assembly that needs maintenance – all these circumstances are prone to produce misprints of some kind. One of the most frustrating things about 3D printing is when you’ve become so excited to print the perfect model, only to end up with a piece of plastic junk.

One of the most common problems that almost all 3D printing professionals have experienced is stringing. This is what the community calls misprints that end up with thin strands or “strings” of filament where there weren’t meant to be any. What causes stringing? What adjustments do you need to make to avoid stringing?

What is stringing and what causes it?

Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. While the extruder does not receive any command to convey the filament while it is traveling along this path, the portion of the filament that has already been melted tends to naturally drip off the nozzle, leaving behind very thin strands of plastic.

Stringing typically happens when a design has large spaces that the print head needs to traverse where no printing should occur. Filaments that require a high printing temperature, such as PETG and Polycarbonate, are also more prone to stringing.

Depending on how bad the stringing is, you might still be able to salvage your build with some heavy sanding and polishing. More often, finishing a build with heavy stringing just isn’t worth the effort, and you’re better off restarting the print with adjusted settings.

Tips to avoid stringing

There is no one-size-fits-all solution when it comes to stringing. Different filaments and different nozzle sizes will likely require varying settings, should you encounter stringing. The good news is that all the tweaks you need to avoid stringing are right in your fingertips – you’ll just need to do some trial and error.

1. Enable retraction

The most reliable method to reduce stringing is to take advantage of your 3D printer’s retraction feature. This should be enabled by default, but its settings can still be refined to get the best results. As its name implies, retraction pulls in a portion of the filament so that there is less pressure on the melt zone. Of course, the filament that has already been melted will remain melted, so it will still drip down eventually.

The critical settings for retraction are the retraction distance, retraction speed, and the minimum travel distance. The retraction distance determines how far back the extruder pulls the filament, and the speed is how fast the extruders rotate to retract the filament. The minimum travel distance is a little more complicated – it is the distance that the printhead will need to travel without printing before retraction kicks in. By reducing the minimum travel distance, you can ensure that there will be no stringing even across small distances.

In your 3D printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. Tweak these settings until you get the best results, although there may still be a few factors in play, as you’ll see below.

If your printer has a Bowden extruder, you will probably need to set a higher retraction distance and retraction speed.

2. Increase travel speed

We know now that, even with retraction, there is no way that the melted portion of the filament can still be pulled back from the tip of the nozzle. If you find that tweaking retraction settings still does not solve your stringing problem, you can increase the speed with which the printhead moves between two points. If you still end up with stringing even when you have optimized retraction, you can try increasing the travel speed by increments of 10 mm/s. It’s possible for this figure to go as high as 200 to 300 mm/s, depending on your 3D printer.

3. Lower printing temperature

The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. By lowering the temperature, you can influence the flow properties of the melted filament to encourage it to stay in the nozzle longer.

Getting the best printing temperature depends on the type of filament you’re using. You can try decreasing your printing temperature by 10 °C increments until you no longer observe any stringing. Just be careful not to go too low, as printing below the recommended temperature range for your filament can cause jamming in the extruder or poor layer adhesion in your build.

For a quick check on the most optimal printing temperature setting for your filament, you can try printing a temperature tower model from Thingiverse.

4. Reduce printing speed

Printing speed goes hand in hand with the printing temperature, lest you end up with under-extrusion problems. If you’ve decided to resort to lowering your printing temperature, don’t forget to set a lower printing speed, as well. It will be easy to see if your printing speed settings are too high relative to the temperature, as you will likely end up with a print with noticeable gaps and holes where the extruded filament can no longer keep with the print head’s travel speed.

5. Make a test print

We find that the best way for you to minimize the amount of filament that will go to waste while you adjust your settings is to make a small “stringing test” print. There are several different models available in Thingiverse for you to check if you’ve got the correct settings, but we like this model made of identical cubes with different separation gaps.

Final thoughts

Stringing is just one of the many issues you can encounter when you’ve decided to take on 3D printing as a hobby or as a profession. It’s just something that will come up eventually and inevitably, especially when you’re working with a filament you’re not familiar with. Fortunately, solving the stringing problem only involves making a few adjustments on your printer settings – there’s no need to get any additional accessories or parts.

While you’re adjusting your printer settings to solve a stringing problem, remember to be patient and take it slow. Don’t adjust multiple settings all at the same time. By adjusting just one parameter at a time, you will see how it affects the quality of the print. You’ll also develop a better understanding of how different printer parameters affect each other. It is through this process of trial and error and learning from your errors that you can become better at 3D printing.