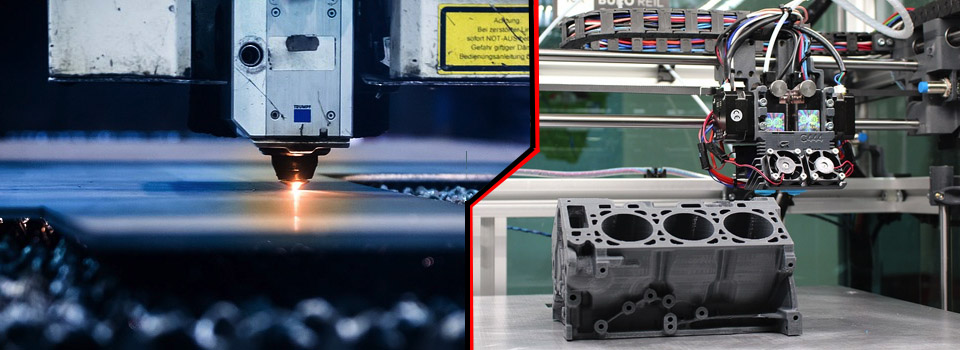

3D Printers vs CNC Machines: What’s the Difference?

You may have noticed that we are quite obsessed with our 3D printers, and have published numerous articles on filament materials, 3D printing accessories, best practices, and best printer brands. In this article, we wanted to spread the spotlight a little to include another similarly popular prototyping technology. Computer numeric control, or CNC, is a method of processing mechanical parts by automation of machine tools. We take a detailed look at how CNC differs from 3D printing, and the advantages and disadvantages of each technology.

What is CNC?

Since we have written in great length about the different technologies of 3D printing in our other articles, it may be more worthwhile to shed some light on what exactly CNC is. As opposed to controlling machines manually using levers of wheels, CNC allows machines to operate based on pre-programmed instructions. These instructions usually come from a computer aided design (CAD) software, from which a 3D design is converted into a tangible object.

The most common CNC machines are mills and lathes, both of which cut or taper from the original material to produce the desired design. There are also more advanced CNC options, such as cutting of material using a plasma torch or a waterjet. Thus, CNC has been dubbed as a ‘subtractive’ prototyping technology since they remove from the original material to create its product.

There is a great selection of materials that can be used in rapid prototyping using CNC. Metals, such as aluminum and stainless steel are extremely popular choices, along with plastics such as ABS or polycarbonate.

What are the differences between CNC and 3D printing?

Additive vs. Subtractive

From the brief description of CNC, you have probably surmised that there are a lot of differences between CNC and 3D printing. Recall that 3D printers extrude hot filament to build layers, one on top of the previous, making it an ‘additive’ technology. This is in stark contrast to the ‘subtractive’ technology of CNC.

Is one technology clearly better than the other? Not really, as they both have their strengths depending on the application.

Complexity of design

Being an additive technology gives 3D printing the advantage of being able to create complex designs with various internal features. Designs with overhangs can be easily remedied by including support structures in the 3D model, or by using technology that does not require support structures, such as selective laser sintering (SLS).

CNC builds designs by cutting down a solid block of material, limiting its machining capabilities to areas that can be accessed by the drill or lathe being used.

Accuracy

What CNC lacks in terms of geometric complexity, it makes up for in accuracy. The accuracy of CNC machining is generally better than that of any type of 3D printing technology, including industrial FDM machines. This is largely due to the 3D printing process relying on heating up and cooling down of the print material, which is prone to shrinkage and warping.

Although most CNC machines offer accuracies in the magnitude of 0.025mm, there are certain FDM printers that offer comparable if not equal resolutions. However, the FDM printing process is vulnerable to a lot of factors – such as ambient temperature, printing temperature, printing speed, and cooling – that can affect its accuracy at a significant level.

Material

Most FDM printers, especially the desktop models, are very limited in terms of the material that they can work with. They mostly use filaments made from some sort of plastic, such as PLA, ABS, PETG, or Nylon. Even the specialty filaments like carbon fiber or wood are basically made using a PLA matrix infused with solid particles. The use of plastics limits the applications of 3D printed objects. They are not very durable and are prone to deforming under high temperatures.

CNC does not have this limitation. In fact, CNC has been used to machine parts from some very durable materials such stainless steel, aluminum, and various alloys. Machining parts out of less durable material such as wood, fiberglass, foam, and even some plastics is also possible. In terms of material flexibility, CNC offers a much larger selection of possibilities.

Speed

For a project of similar size and complexity, a CNC machine can typically finish much faster than a 3D printer. The additive method of 3D printing means that very thin layers are built on top of each other, which is a very slow process that may take several hours to complete. A 3D printed object also usually needs some form of post-processing before it is used for its original purpose. Most users do polishing and acetone vapor misting to get a smooth and sleek finish out of their 3D printed objects.

In contract, a CNC machine cuts and chips from the material block using a sophisticated set of drills, mills, and lathes. These operate very quickly – a project that will take a 3D printer several hours may even be completed by a CNC machine in an hour or less.

Cost

Due to their popularity, desktop 3D printers nowadays have become very cheap and easy to buy. Filament materials are also quite cheap, with several manufacturers selling their own versions of pretty much the same types and variants. For one-off prototypes, the smaller initial cost of 3D printing is justifiably low and makes it the better option.

The more complex and industrial-sized CNC machines are generally more expensive. Drills, lathes, and other mechanical parts also have to be replaced regularly as they can get worn down after repeated use. The high costs associated with CNC makes it more practical when producing multiple prototypes quickly and regularly.

Waste

As it is a subtractive technology, CNC definitely produces more waste than 3D printing. To be fair, the scrap metal or wood that is produced after CNC machining can be recycled. However, this just another concern you have to bother with. The CNC machining process is also inherently noisy and creates a great deal of vibrations. This means that you will need to house a CNC machine in an isolated room where it won’t bother anyone.

In contrast, 3D printing produces a much smaller amount of waste. The most common waste materials in 3D printing are misprints made from standard filament materials. Most plastics are not biodegradable, but the thermosetting plastics used in 3D printing can be recycled and repurposed into new filament. One of the most common 3D printing plastics, PLA, is even fully biodegradable. With a little diligence in the use and reuse of resources, 3D printing can be a very low waste activity.

Ease of use

With the widespread use of desktop 3D printers, 3D printing technology has now developed to a degree where it has become very accessible and easy to learn for new users. Free 3D models can even be downloaded from various websites to help you become familiar with your printer. This means that a high skill level is not necessary for you to come up with basic 3D prints.

In contrast, CNC machines can be bulky and complex machines that require a specific set of skills to operate. Making a prototype using CNC can involve choosing and changing tools, repositioning of the material block, and general maintenance activities such as lubrication of moving parts. Thus, it is a much more labor-intensive activity.

Which technology is better?

There really is no clear-cut winner on which technology is better, as they both have applications where they can both excel at. For quick and cheap prototypes made of plastic, 3D printing is obviously the better option. 3D printers also hold the advantage in making models with complex geometry. They are cheap, accessible, and easy to use.

CNC machines have the advantage of flexibility in terms of the material it can work with. Durable materials, such as metals and wood, are standard materials used for CNC-machined parts. CNC also produces prototypes of similar size and complexity much faster than 3D printing. However, they are limited in the complexity of the parts that they can produce. They are also quite expensive, making them more practical for mass production of prototypes and parts.

In the end, each type of technology has its merits. If you are considering one or the other, you may want to consider which aspect you deem important, whether that be the cost, the speed of production, or the complexity of design. By considering the specific application you are aiming for, a clear and practical better option is easily determined.