3D Printing and Woodworking – A Perfect Combination

Before 3D printing, there was woodworking.

Woodworking has been one of the favorite hobbies of those who like to work with their hands. There was a certain fulfilling – perhaps even meditative – value to creating beautiful and useful things from planks of wood.

Some would describe 3D printing as the more modern version of woodworking. Although 3D printing demands different technical skills, the end goal is still to come up with something valuable out of raw materials.

If you’re interested in both, then there’s no need to pick just one. Woodworking and 3D printing are crafts that work incredibly well together.

3D printing vs. woodworking – key differences

Woodworking and 3D printing can be described as the two sides of the same coin. They are both manufacturing methods but go about using vastly different approaches.

Additive vs. subtractive

Woodworking is a classic example of subtractive manufacturing. This means that the final product is derived from a slab of raw material by chipping or cutting away the material that is not needed. This method inevitably generates more waste but produces finished parts that are mechanically stronger.

3D printing is the very defining example of additive manufacturing. Instead of cutting away from a large block of material, a 3D printer product is built layer by layer. This method generates less waste but is also usually slower. An unfortunate consequence of 3D printing is that it is almost impossible to achieve the same mechanical integrity as a piece made via subtractive manufacturing.

Cost

In terms of the equipment, woodworking would likely require much greater capital. Between the various types of power tools and hand tools you will need, you will probably have to spend between $500 to $1000. It will be even more expensive if you’re getting a CNC machine like a lathe or mill.

In contrast, 3D printing can be done with just a single 3D printer and a few basic hand tools. If you stick to entry-level 3D printers, you should not need to spend more than $500. 3D printers have gotten a lot less expensive in the last years, paving the way to the widespread use by hobbyists.

Skill level

Woodworking is an old-fashioned craft. This means that it requires substantial training or experience, especially if you’re working with lots of power tools. Someone who has never worked with these tools before isn’t likely to be able to create a good wooden desk over a single weekend.

3D printers are much more beginner-friendly. Although there are complex algorithms involves in running a 3D printer, most of these happen behind the scenes and do not need to be bothered with by average users. Most desktop-scale 3D printers are designed specifically so that even pure beginners can start printing in just a few minutes.

Those who do CNC woodworking can adjust much easier to 3D printing. CNC technology, after all, is also based on digital 3D models. As we shall see later on, 3D printing can have a unique case for those who use CNC machines for manufacturing.

3D printed woodworking accessories

3D printing truly shines as a complementary craft to another hobby. This characteristic also applies to woodworking. You might have all the power tools set up, but there are so many ideas out there of “ad hoc” tools that are similarly useful. Here are some of the most popular:

Sanding sticks

Sanding tight spots in a wooden project can be challenging. You typically just wrap sandpaper around some arbitrary tool or just get your finger in there. This works eventually but is not very efficient.

These sanding sticks are designed to hold a strip of sandpaper in place with its clamps and thumbscrews. The sticks are available in various shapes and sizes, so you should not have a problem finding the one that you need. Although very simple, these sanding sticks can reduce the time and effort it takes to sand very small spaces.

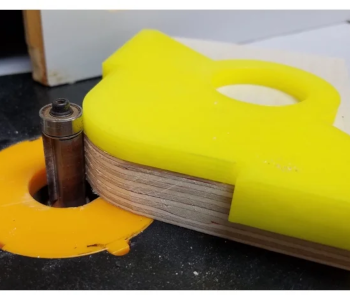

Corner radius rounded corner template

Drawing the outline of a rounded corner on a wooden slab is easy. However, cutting away that rounded corner using a router takes considerably more skill.

This rounder corner template is designed to fit into any sharp corner and serve as the template for the router. The STL file contains nine different templates with varying corner radius values. The corner template will very briefly come in contact with the router, so it’s best printed with a thermally stable plastic like ABS or Nylon.

Universal clamping blocks

Putting together corners whether they are mitered or have wider or narrower angles is hard because they cannot simply be clamped together. The common solution to this problem is to glue temporary clamping blocks to the pieces that form the corner. This takes so much time and adds unnecessary work.

With these 3D-printed universal clamping blocks, you can say goodbye to all those creative solutions. These clamping blocks have circular levers that can be clamped tight, regardless of angle. It’s a very simple contraption that you might be left wondering why you did not have such a tool in the first place.

Vice jaws

This is another simple but useful idea – plastic jaws that you can affix to your vice so that it does not damage more fragile materials. This is best 3D printed with a plastic that is moderately flexible such as PLA. The vice jaws also work wonderfully with hard materials like wood as they can more effectively clamp the piece.

The vice jaws have small indentations on the bottom side. These are meant to house small magnets so that they can be attached and detached from your vice easily. They can also be glued onto the vice. There is really no disadvantage to just affixing these jaws to your vice permanently.

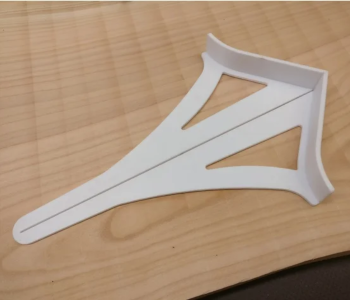

Universal center finder

Woodworking experts are also experts in finding the centerline of everything. A rectangular plank of wood is no problem, but those that have rounded corners require a bit more imagination. In any case, finding the centerline using old-fashioned methods takes a lot of time.

This universal center finder is a handy tool that you can 3D print quickly. The fence of the tool is specifically designed to fit both round and rectangular corners. There is also a small relief on the fence so that it can fit any piece that has burrs. A thin channel runs right down the middle so that you can mark the centerline with a pencil.

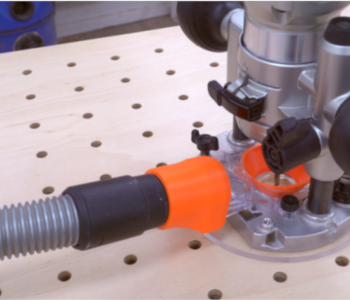

Dust collection adapters

Dust collection is a crucial part of woodworking. Not only does wood dust get into your respiratory system, but it can also very easily cause a fire or dust explosion. Unfortunately, getting your dust collection hoses to fit with your vacuum units is an impossible task without adapters.

There is a whole slew of 3D printable dust collection adapters out there with different shapes and sizes. The model we are linking to here allows a Makita RT0070CX2J dust shroud to connect with smaller 36-mm hoses. If there’s a mismatch between any of your dust collection equipment, just do a quick search and you might just find the exact adapter you are looking for.

Parametric knobs

By far, this set of parametric knobs will likely be the most useful to any woodworking enthusiast. You can choose to integrate nut knobs for your finished product or use them as adjusters for jigs or create makeshift screwdrivers.

This STL file contains an array of nut knobs, wing nuts, and mini bits for hex and star screwdrivers. Yes, just about all of these parts can be purchased in your local hardware. However, that can get expensive after a while because these plastic nuts can break apart fairly easily. It’s much more prudent to 3D print a bunch of them so you can have one ready when you need it.

These plastic knobs can be made to fit snugly to any fixture by just heating them momentarily. You can also apply some glue for extra bond strength.

Cordless tool wall mount

When you start accumulating lots of power tools, getting them organized becomes more challenging. You will want to put them away but in a manner that still makes them accessible. How about wall mounting them?

This 3D printable bracket fits most of the Dewalt and Makita cordless tools. They can be screwed onto a wall or tacked into a secure pegboard. With a simple and elegant design, this wall mount can help you reclaim horizontal space in your workshop.

3D printed prototypes

A subset of woodworking involves the use of CNC machines. These are typically mills or lathes that can run automatically based on an established algorithm. CNC woodworking is ideal for creating high-precision parts that require detailed etching.

A key characteristic of the CNC process is that it starts with a 3D model. This 3D model is processed in a CNC software platform to generate the code that the CNC machine will follow. This code or algorithm determines the exact movement of the machine’s cutting tools and other moving parts. Some in the industry call this “digital woodworking” and this technology has given way to some of the most impressive woodworking projects.

The beauty of combining CNC machining and 3D printing is that they can both be done using the same 3D model. For those who plan their builds in CAD platforms, 3D printing provides a way to quickly come up with prototypes. Do you want to test how a 4-foot sculpture will look before fully committing to it with wooden parts? Then print a small-scale replica of it over one afternoon.

Those who offer professional woodworking services can greatly benefit from 3D printed prototypes. A 3D printed copy is a great way to review a model with a client for approval or possible revision. Looking at a 3D model is a computer screen simply cannot compare to holding a physical copy in your hands.

More innovative woodworking enthusiasts have been trying to integrate 3D printing and woodworking in different ways. As 3D printers become more sophisticated, it’s not hard to imagine 3D printed projects going hand-in-hand with wood not just as prototypes but as finished parts. This seems to be the direction that the manufacturing industry is headed. Until then, 3D printing could remain the perfect complement to woodworking.

Final thoughts

Woodworking is a respectable craft. It has been around for centuries and has only been made better by modern equipment. Nowadays, wood craftsmen are capable of designs and products that would not have existed ten years ago.

With 3D printing on the rise, there is again an opportunity to advance the possibilities of woodworking. 3D printing is not a competitor or alternative to woodworking. In many cases, 3D printed parts can be very useful in creating new possibilities for woodworking. Combining both may just give way to a brand new craft.

Hi, how do I get the design files and what are the copyright implications in 3D printing and selling say the sanding sticks for example? Or another example are the 3DP items for woodworking on Etsy. I’d love to creat and sell a few of them and the stores usually sell the design files for download. Would I be able to build and sell those? Or would I have to design my own. If I have to design my own how would I learn to do that? Thanks