The Future of 3D Printing for Architecture

Like so many other technological advances, 3D printing was also slow to get off the ground. In more recent years, however, people are talking of little else. The fast and fascinating developments in this amazing technology are making everyone and every industry sit up and take notice. Architecture is one area where 3D printing is making a lot of headlines, and it will continue to do so in the years ahead. In this piece we explore what the future potential holds. We also look at the current limitations of 3D printing within the construction industry.

What You Will Learn from this Guide

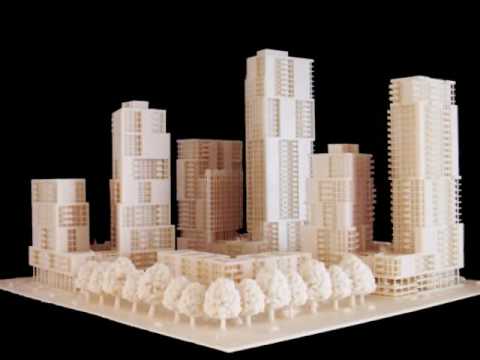

Right now, 3D printed buildings are still very much in the experimental stages. As you read through this guide, you will learn of the current technologies, materials, and trials in this exciting area of construction. You will see how 3D printing is going to play a future role in creative building, not only homes but entire urban sections of towns and cities. You’ll understand how it becomes cheaper and faster to produce 3D digital models and create new parts. By the end of this guide you’ll have a much better understanding of the way architects design and develop 3D building structures and geometries.

The Dawn of 3D Printing

Before we get into 3D printing and architecture, let’s pause for a moment to see how the technology first began. We can trace its beginning back to 1976—a time when the first inkjet printer came to be. Architectural 3D printers are like inkjet machines in that they both need data files to print from. For 3D printing, the common, universal file types are VRML and STL. Regular inkjet printers take their instructions from various types of word processing files like .docx, .odt, and .txt, etc. They can also print from other file formats from popular office suites such as Microsoft.

OK, now fast forward to 1984. This was the year when scientists and engineers had begun to experiment with printing materials other than ink, and so 3D printing was born. Despite this revolution in 3D printing technology, it would be some 30 years until the general public began to show any real interest in the technology.

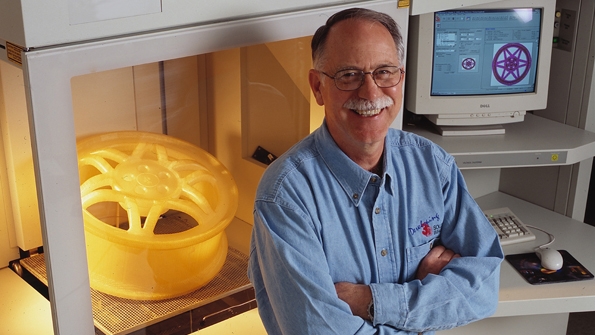

Meet the Father of 3D Printing

We can attribute 3D printing technology to an American engineer and the co-founder of 3D systems, Chuck (Charles) Hull. He invented the first printing process that was capable of creating an actual, physical 3D object from a digital data file. He called this process Stereolithography. In an interview, Hull admits how surprised he was of the capabilities and potential of his discovery. And however amazed people were of 3D printing in its infancy, few could have imagined where it was heading.

Today, all sorts of industries use this technology to create 3D models from digital files. The beauty of this is that it allows users to fully test a certain design before making a decision to invest in larger manufacturing projects and programs. It’s even finding its way into homes, schools and libraries as the technology advances and the prices continue to fall.

So there you have it. 3D printers are not dissimilar to inkjet printers. The main difference is that they deposit different types of materials in successive layers. Inkjet printers only extrude a single layer of regular printing ink.

The Benefits of 3D Printing in Architecture

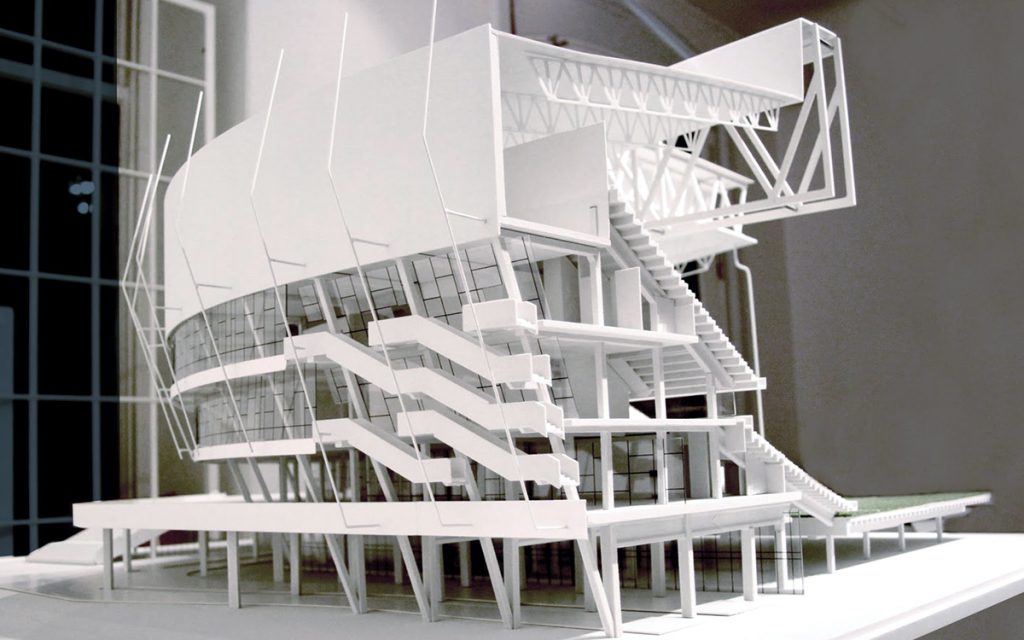

Architecture often involves complex designs of impressive structures, and we see and use most of these buildings in everyday life. Many designs illustrate an artistic interpretation that represents the architect’s style and work. From the client or prospect side, flat, 2D drawings don’t tell much about how an end structure will look. This is why architects use artist’s impressions and 3D models to illustrate their creations. In the past, this was long and laborious work. Oftentimes, a project would have to return to the drawing board for multiple reviews and modifications. Today, this entire process has become, and continues to get, much easier, cheaper and faster. This is all thanks to the advancement of 3D printing technologies.

Like all new technologies, early theories, products and equipment are always expensive. The 3D printing concept was no different in this regard. But early hurdles never last forever, not with great ideas. As soon as others saw practical applications and the future potential of 3D printing technology, things began to change. All of a sudden, bigger and better resourced companies began to invest. This is often how new innovations get to really take off. Products then start to improve, and prices begin to drop. We can say with confidence that 3D printing is now here to stay, and we haven’t even begun to see its full potential in 3D architecture yet.

Seeing Is Believing

Clients prefer to see an architect’s idea more than hearing about it. Today this is possible because 3D printing allows the creation of scale models much faster. This means architects can produce durable, complex models in-house, direct from computer-aided design (CAD) data files. These are not rough models either. What we have are amazing, smooth, detailed architectural prototypes that a 3D printer can produce using an array of different materials.

Time Is Money

How long it takes to produce a 3D model from scratch depends on the size, scale and complexity of the design. One thing is certain, and that is it takes a lot less time using 3D printing technology. To give you some idea, let’s take a model that would normally take two people two full months to complete. With 3D printing technology, a single person could probably achieve the same thing in a matter of hours. It’s not difficult to find plenty of case studies that illustrate the improved quality and time savings of using 3D printing for architectural designs.

To summarize, here are the three key benefits of 3D printing for architects:

- Detailed 3D printed models help clients to better visualize final projects

- Reduced time (hours and days) spent creating models

- Over time, Architects can build a library of reusable 3D designs

Fortunately, 3D printing has given a real positive boost to architects in recent times. It not only helps them to improve the quality of their designs, but also reduces the time it takes to produce architectural models. This is something that benefits all parties—architects and clients. If 3D designs and printed models stopped here, this alone would be an impressive advancement in the world of architecture. However, like all emerging technologies, a lot of people have much greater things planned for the use of 3D printing as a way forward.

3D Printed Urban Structures

You may be wondering what other areas of architecture could possibly benefit from 3D printing after the design process. Well, how about 3D printing actual buildings and other urban structures as well as 3D models. It may sound like pie in the sky, but it’s not. In fact, the world’s first ever 3D printed footbridge recently opened in Madrid, Spain. The architects used micro-reinforced concrete as the material to print the structure. Measuring just 12m in length by 1.75m wide, this impressive little footbridge spans across a small stream in Castilla-La Mancha Park. And like all ‘firsts’ you can guarantee that greater things will follow as expertise and technology improves.

A Cleaner Way to Construct

3D printing used in architecture could also be a greener solution to modern construction. Let’s take the 3D bridge above to illustrate this point:

- Design allowed for optimal distribution of 3D print materials

- Amount of waste minimized thanks to the smart recycling of raw materials

- Material used during construction only went where it was needed

- Printing process allowed complete freedom with regards to form

- End design showed maximum structural performance

The bridge was a small project, but it still took 18 months from the design stage to its construction. Even so, it has been a huge leap forward in 3D architecture. Although there are other, similar projects in the pipeline, the Madrid 3D printed bridge was the first of its kind to finish.

The Road Ahead in 3D Printed Architecture

We’ve seen the 3D printed bridge, and now you may be wondering what’s next. The technology to 3D print houses, as in real homes that people can live in, is already on the way. Australian researchers think this is going to bring a lot of unique advantages to housing markets around the world. These advantages would result in buildings that are quicker to build and cheaper to produce. There’s still a lot of experimentation going on with building structures right now, but it’s only a matter of time.

For instance, a Swedish company recently printed an entire home out of concrete for $10,000.

Here are some common applications for real 3D designs and architectural rendering projects:

- 2D-3D Floor Plans

- 3D product modeling

- 3D architectural modeling

- 3D architectural rendering

- 3D bird view rendering

- 3D elevation design

- 3D exterior concept design

- 3D interior concept design

- 3D Walk-through

- Landscape Design

- Others

Materials Used in 3D printing Architecture

The University of New South Wales in Australia is actively researching 3D printing possibilities in the construction industry. Associate professor, M. Hank Haeusler has a team that’s looking into the practical use of two common materials used in 3D printing:

- Poly Lactic Acid (PLA)

- Acylonitrile Butadiene Styrene (ABS)

This research looks into 3D printing large-scale components out of ABS or PLA. On their own, neither of these materials is structurally sound, so the solution here it to use them with carbon fiber. The use of lightweight carbon fiber gives either of these materials the strength of steel. It should be possible to create these parts off-site and deliver then on-site as needed. Additionally, printing 3D parts on-site, on-demand, using clay and concrete type materials is also an area the research team is looking into.

Reduced Housing and other Construction Costs

Because 3D printed applications are not yet widespread in architectural solutions, it’s hard to crunch the numbers. Nevertheless, professor, M. Hank Haeusler has no doubt in his mind that reduced cost savings in the building industry are going to be a major advantage going forward. He even dares to predict that 3D printing technologies will only take about one third of the current cost of standard construction projects. That’s a huge difference. It would also mean that architects and builders give the thumbs-up to new projects faster and build housing and other structures quicker. The long-term contribution this could add to help with the current global housing crisis is mind-blowing.

3D printed homes will look quite different to the more conventional structures we’re familiar with to. And like all new designs and technologies, there will be those who love them and those who think they’re ghastly. It’s a fact of life that few people want to be the first when it comes to big changes. It doesn’t matter how cheap a 3D home is, it will only take off if people actually want to live in them. That’s nothing for now, but it’s certainly food for thought as the first big projects materialize. Still, with the current high cost of housing, it’s unlikely there’ll be a short supply of clients looking to invest in more affordable homes.

Whether 3D printing proves to be the way out of this crises remains to be seen, but it’s looking good. One of the major setbacks at the time of writing is that there are not any regulatory frameworks in place for 3D printed buildings. In most countries, new building techniques and materials still need approval, and these are things that can take time.

More than Just Housing

Although urban housing is a huge deal, there’s more to 3D architecture than just the future of 3D printed homes. If it’s a structure, there’s a good chance it has a future in 3D printing. But right now, there are lots of useful applications that 3D printing can provide to architect’s designs.

Early stage models: Concept models are quick and easy to produce. The moment you have your model you can begin discussions with clients and prospects. This saves time and money, reduces the risk of costly errors, and speeds up the entire design-to-agreement process.

Urban planning: Architects now have the ability to 3D print a model of an entire town or city. This is something that’s achievable within hours with the right equipment and print materials.

Model variations: Sometimes it’s useful to print a few variations of the same or similar models. This is an affordable way to help architects get to their final designs faster and with much less fuss.

Summing Up

Right now, architects the world over say that 3D printing is proving to be a Game Changer for architectural design. There’s no question of doubt that it drastically improves architectural model production. This results in more meaningful communication with clients. These things alone will help to secure more projects going forward. For now, real-world 3D printed structures are still at the infancy stage. Despite this, most agree that this is an area where we’re going to see a lot of new developments in the not too distant future. As the technology advances, there will still be regulatory hurdles to overcome before 3D printed buildings become commonplace.