Biofilaments for 3D Printing – What They Are and Where to Buy

If there’s a persistent flaw in the 3D printing process, it’s that it relies exclusively on plastic as raw material. This have given 3D printing a pretty bad rap, especially in today’s more environmentally conscious society. There is nothing wrong with that, of course.

Fortunately, there are now many 3D printing filaments that are better aligned with a more environmentally friendly mindset. These are called ‘biofilaments’ and pertains to filaments sourced from sustainable sources. How do biofilaments perform in 3D printing and are they worth a shot? What are the best biofilaments that you can buy today?

What are biofilaments?

Biofilaments pertain to filaments that are made of bioplastics. These are plastics that come from sustainable sources, typically plant matter. One of the most popular bioplastics is already well-known to the 3D printing community – PLA.

Bioplastics, and biofilaments by extension, are a way to maintain the use of plastics without depending too heavily on depleting oil-based resources and avoiding the accumulation of non-biodegradable solid waste. This is very important in 3D printing considering how almost all the filaments are made of single-use plastics.

The good news for environmentally inclined 3D printing enthusiasts is that there is now a wider selection of biofilaments aside from plain old PLA. Most of these are still based on PLA but feature exotic additives that enhances their visual qualities.

However, bioplastics are not the all-around Earth-friendly solution that they are being marketed as. There is a huge controversy on the sustainability of bioplastics which also translates to biofilaments.

Pros and cons of biofilaments

The specific characteristics of biofilaments are difficult to discuss because they can be so varied. Unlike other filament categories, biofilaments can be made of different plastics or have different additives. However, we can still narrow down the common traits of bioplastics and classify these as benefits or drawbacks.

PROS

Sustainable

First off, bioplastics are great for those who want to continue 3D printing but no longer want the mental and emotional burden of contributing to the planet’s solid waste problem. Bioplastics come from sustainable sources, have a smaller carbon footprint, and can be broken down into compounds that are safe for the environment. Although they aren’t entirely “green,” they certainly qualify as the lesser evil.

Less toxic components

Another happy consequence of biofilaments coming from plant-based sources is that they do not have toxic compounds. This makes them safe for biodegradation. More importantly, this means that printing with biofilaments should be safer for you and the other people you may be working with.

Easier to dispose of

Manufacturers of bioplastics have made a huge deal about how these plastics are biodegradable or compostable. Biofilament manufacturers strive to retain this benefit by integrating bioplastics with other Earth-friendly additives. Theoretically, these biofilaments can be disposed of in a compost and will break down via biological agents. They will then break down into compounds that are not hazardous to the soil or to animals.

CONS

Poor mechanical properties

In most cases, bioplastics have inferior mechanical properties compared to their petroleum-derived counterparts. There is no doubt that common non-biodegradable plastics like Nylon and PET are so much more robust than PLA or starch-based plastics.

This fact becomes even more prominent in bioplastics that infuse solid particles into a PLA matrix. While these look great, combining powdered solids with PLA reduces it flexibility and malleability. The result is a material that is brittle, has poor impact resistance, and low heat stability. There are lots of biofilaments out there that are good for nothing more than their visual appearance and for appealing to the green crowd.

Not quite as “green” as we believe

Here is the big controversy of bioplastics – they may not be as Earth-friendly as have been made to believe.

One major selling point of bioplastics is that they can be disposed of in a compost. What many bioplastic manufacturers fail to mention is that breaking down bioplastics requires very specific conditions that can only be attained in industrial facilities.

In a backyard compost, a bioplastic like PLA will likely take more than ten years to break down. When bioplastics are not disposed of properly, they can still break apart into microplastics that fish and other animals can ingest. This puts us right back at square one – plastics that create a solid waste problem while causing harm to wildlife.

The ethics of creating plastics from plant matter has also been questioned. While it’s true that plant-based matter is a renewable source, using up this resource to create plastics isn’t necessarily a good while there is persistent food shortage in many parts of the world. In fact, it’s impossible for all single-use plastics in the world to be converted to bioplastics without seriously compromising our planet’s food supply.

In summary, shifting to biofilaments from the usual filaments like ABS, Nylon, and PETG will mean compromising in a lot of areas. It’s certainly the more Earth-friendly option although we prefer that our readers have a more realistic perception of just how “green” bioplastics are.

Where to buy biofilaments

Just to manage your expectations, almost all biofilaments sold today are based on a PLA base matrix. After all, this is the most easily available bioplastic that we know is suitable for 3D printing. Although there are PLA composite filaments with additives that are not considered biodegradable, we curated this list to include only biofilaments.

1. HATCHBOX PLA Filament

PLA is one of the most popular 3D printing filaments and is carried by just about every filament manufacturer. We are highlighting the PLA filament from HATCHBOX here because of the incredible value for money, but there are several dozen other filament brands out there. PLA is inexpensive, easy to use, does not emit unpleasant fumes during printing, and is widely known in the 3D printing community as a plant-based biofilament.

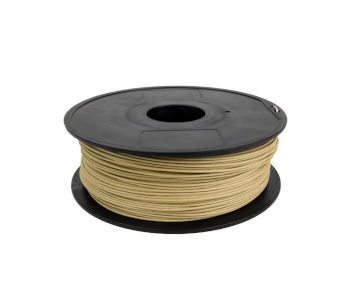

2. Gizmo Dorks Wood Filament

A common “remix” of the standard PLA filament is a wood filament infused with real wood particles. This wood filament from Gizmo Dorks is one of the more reliable options but is also quite plain. If you want something fancier, there are also filaments that simulate the look of dark wood or cork. Wood filament is one of the more classic and widely used biofilaments used simply because of the rustic charm of wood.

3. Wound-Up Coffee-Infused PLA Filament

The filament lineup of the 3DFUEL brand is one of the most creative in the industries. The Wound-Up PLA filament has been infused by waste material generated from the coffee making process, giving it a unique appearance with minimal carbon footprint. A unique and pleasant characteristic of this filament is that it emits the aroma of coffee while printing. With Wound-Up, 3DFUEL makes a strong case for producing innovative and creative filaments from recycled waste.

4. 3D Fuel Biome3D Filament

Biome3D is one of the very few biofilaments in the market that is not made of PLA. Unfortunately for us, 3D Fuel isn’t forthright in exactly what this filament is made of. According to the product brief, this filament is made from plant materials and has many of the desirable qualities of PLA like minimal warping. However, 3D Fuel also claims that Biome3D has the flexibility and surface finish of filaments that are petroleum-based.

5. Landfillament Waste PLA Filament

There is likely no other filament that strives to be as nature-friendly as the Landfillament. Another innovative filament from 3D Fuel, Landfillament has a PLA matrix combined with pyrolyzed waste material. The waste that goes into Landfillament is municipal solid waste – perhaps this may have literally been collected from a landfill. The result is a filament with a deep black color because of its high carbon content.

Final thoughts

In a bid to make 3D printing more Earth-friendly, many in the 3D printing community have been open to pivoting to the use of biofilaments. These are an offshoot of bioplastics or plastics manufactured from plant-based sources.

Biofilaments are a bit more sustainable as 3D printing material. There are a lot of them nowadays in a variety of different materials and designs. Although they have several weaknesses, they remain the filament of choice for 3D printing enthusiasts who are conscious about their carbon footprint.

Despite the strength of biofilaments, we advise our readers to be wary of buying into “greenwashing.” Bioplastics are not the absolute solution to the growing plastic waste problem – at least, not yet at their current form. It’s still a good idea to minimize waste from 3D printing, even if you’re printing exclusively with biofilaments.