Should You Worry About 3D Printing Fumes?

Although 3D printing in your workshop or office seems like a benign activity, there are still some hazards you should watch out for. Aside from the usual hazards of working with electronics and components that can be heated to more than 200 C, the fumes generated by heating the plastic filaments have always been a cause of concern for 3D printing professionals.

What exactly are the fumes released in 3D printing and are these fumes something you should be worried about? If so, what are the best practices to keep yourself and the other people around you safe during 3D printing?

What fumes are created during 3D printing?

Toxic fumes

The composition of the fumes generated during 3D printing, and thus their level of toxicity, depends on the chemical composition of the filament being used. Much has been written about how extra care needs to be taken when printing with ABS, which also happens to be one of the most widely used filament materials in FDM printing.

Many studies have shown that ABS produces a gas called styrene when heated. When inhaled in high concentrations, styrene can cause drowsiness, headaches, and an overall feeling of fatigue. Based on recent research, it has also been declared a probable carcinogenic compound and has been linked to increased cases of acute myeloid leukemia. Exposure of nylon to heat has also been found to cause a release of styrene.

Both PETG and nylon are known to emit a VOC called caprolactam when exposed to heat. Although caprolactam has no proven carcinogenic effects, short-term exposure of workers to caprolactam have been found to irritate the skin, eyes, nose, and throat. Those who have inhaled caprolactam have also experienced headaches, malaise, feelings of confusion, and nervous irritation. Chronic or long-term exposure may result in the peeling of the skin.

PLA has often been hailed as one of the few non-toxic materials that can be used for 3D printing. Derived from organic compounds, PLA is a fully biodegradable plastic and is biologically compatible enough to be used for medical tools and implants. When exposed to heat, PLA releases a chemical called lactide. This is a non-toxic chemical that smells sweet and is generally not irritating. However, long-term exposure to lactide is still not recommended.

One other thing to take note of is that PLA is often sold with a host of additives to modify its color and other physical properties. While the PLA matrix is non-toxic, the additives may be a completely different matter. This is the reason why you should carefully read the labels on the filaments that you’re buying, even on spools of PLA.

Nanoparticle emission

Even when working with PLA or any other filament material, the process of melting and extruding plastic results in the emission of nanoparticles. These particles can be smaller than 0.1 micron and can be inhaled or absorbed through the skin. Absorption of nanoparticles can lead to a host of pulmonary problems such as bronchitis and asthma. They can also lead to the development of certain types of cancers.

ABS fares poorly compared to PLA, even in the aspect of nanoparticle emission. ABS has been found to release 3 to 30 times more nanoparticles than PLA. Other filaments that have been tested and found to release nanoparticles include PETG, nylon, and polystyrene. According to the research, it takes between 10 to 30 minutes for the nanoparticle concentration of the air in a room to go back t normal levels after 3D printer extrusion has stopped.

Best safety practices while 3D printing

A piece of oft-repeated advice when setting up a 3D printer is to do it in a room with good ventilation. Garage workshops are ideal because you can open up a few windows and you don’t need to stay in the workshop while the 3D printer does its work. 3D printing in your living room, bedroom, office, or any place where people need to stay in is not a good idea. If it can’t be helped, it would be best to have a strong fan or air purifier in the same room.

This is sound advice on a practical level, but there are many ways for you to enhance your safety measures with a few equipment. Here are our recommendations:

Air extraction

According to experts, a well-ventilated room appropriate for 3D printing should have a venting system that can move three times the volume of the air in the room within an hour. This means that merely opening your windows may not be enough – you will need a system that will actively suction out the air in your workshop and allow fresh air free of fumes and nanoparticles to come in.

A convenient air extraction solution is the Holmes Dual-Blade Window Fan. This window fan can be mounted on most standard-sized windows with its expandable screen and side extenders. It has a reversible airflow feature, so you can use it to either bring fresh air in or draw out the air in your room. With two speed settings and adjustable thermostat, this window fan can ensure good ventilation in your workshop while also keeping the room at a comfortable temperature.

Air quality monitor

Without an air quality monitor, determining if the level of fumes and nanoparticles in the air inside your workshop ends up becoming a matter of guesswork. To make sure that you have the proper safety measures and that you aren’t compromising anyone’s health, an air quality monitor is a very good investment.

One of the best options we’ve seen is this Indoor Air Quality Sensor from UHOO. This 9-in-1 air quality sensor monitors particulate matter concentration, VOC concentration, carbon dioxide, nitrogen dioxide, allergens, air pressure, temperature, and humidity. It has wireless and smart capabilities so you can monitor the quality of air in your workshop remotely from your phone.

To be clear, commercially available indoor air quality sensors aren’t going to completely detect all the airborne hazards that come from 3D printing. Styrene, in particular, is difficult to detect, as are very small nanoparticles. However, any information that this monitor can provide can still be useful if you’re about the effects of 3D printing on your health.

3D printer with a built-in filter

When shopping for a 3D printer, you need to make sure that the model you’re buying comes with the appropriate safety certifications. The well-known ones are CE, FCC, C-Tick, and WEE i. These are typically found in other electrical devices and appliances and mostly relate to how safe the product is in terms of mechanical and electrical integrity.

Many 3D printers being sold right now also come with built-in high-efficiency particulate air (HEPA) filters. A certified HEPA filter must be able to remove 99.97% of all particulates that are 0.3 microns or larger. Take note that nanoparticles released by plastic extrusion can be smaller than this, but any measure that can lower particulate concentration in their air will still be useful.

The 3DWOX Printer from Sindoh is a good example of a 3D printer that comes with a built-in HEPA filter. The Digilab 3D45 from Dremel goes on a different strategy by combining a carbon filter and a particulate filter. While a particulate filter retains solid particles entrained in the air, a carbon filter is a more effective means of neutralizing chemical gases. For more effective removal of styrene and VOCs, a printer with a carbon filter would be preferable.

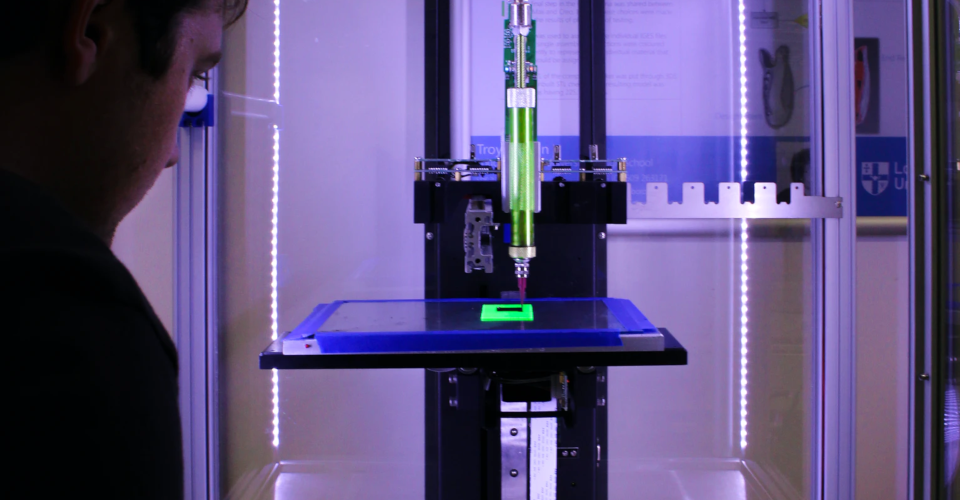

3D printer enclosure

Fumes and nanoparticles are mostly released by a 3D printer at the point of extrusion. A good way of limiting how much of these contaminants go into the surrounding air is to isolate the printing chamber. Nowadays, many desktop-scale 3D printers have taken this safety measure into consideration. The aforementioned Sindoh 3DWOX Printer and the Dremel Digilab 3D45 are good examples.

The trapped air still has to go somewhere, so these 3D printers with enclosures should also have a built-in filter. By funneling all the air into filters, you have a better chance of keeping the air you breathe free from contaminants.

The benefits of a 3D printer enclosure are two-fold. A good enclosure also allows better control of the temperature of your print chamber. This may be necessary when printing with filaments that have to be printed at high temperatures and have a tendency to warp. In fact, an enclosure is practically a requirement when printing with filaments like ABS or nylon.

Room air purifier

Sometimes, you have no choice but to set up your 3D printer at a spot where people normally congregate. If you’re setting up a 3D printer in your living room, then a room air purifier is an absolute necessity. The Winix 5500-2 Air Purifier is a good option among countless others.

The 5500-2 is a compact air purifier that combines a HEPA filter, an AOC carbon filter, and PlasmaWave technology. The three-stage purification technology removes particulates, dust, microbes, and mold spores. It also neutralizes smoke, odors, and chemicals. The purifier has capacity for a 360 sq. f.t room, which should be big enough for your workshop or living room.

While each one of these safety measures is effective on its own, nothing is stopping you from combining several of them in your 3D printing setup. You may also consider consulting firms and organizations that offer 3D printing services professionally and take a look at how they ensure that their operations are safe.

Final thoughts

3D printing is an incredibly fun, useful, and potentially lucrative hobby. Pointing out the hazards that are inherent to 3D printing does not mean that we discourage people from taking it up casually, but we merely want our readers to make informed decisions.

Keeping yourself safe while 3D printing requires knowing the hazards you’re facing and coming up with appropriate measures. The products and methods we have listed here definitely help to some degree, more so if you use several of them together.

Right now, the 3D printing industry has no set safety guidelines yet. Not all 3D printers come with enclosures or HEPA filters, and it can also be argued that even a HEPA filter doesn’t provide 100% protection. As the industry grows, we are hoping that standard safety measures can be enacted in all 3D printers, especially those that are marketed towards casual and home-based users.