A Glossary of 3D Printing Terms – Definitions of 3D Printer Terms

Every field has its language, and mastery of this language can be a struggle even with years of experience. The same can be said for 3D printing. Whether you’re only starting to become interested in 3D printing or have been doing this as a hobby for quite some time, there is probably some jargon that you have not heard of before.

This glossary is our attempt to make navigating through this jargon easier for everyone.

3D modeling – The process of creating a design in 3D space, typically by using a CAD program. Not all 3D models are suitable for 3D printing.

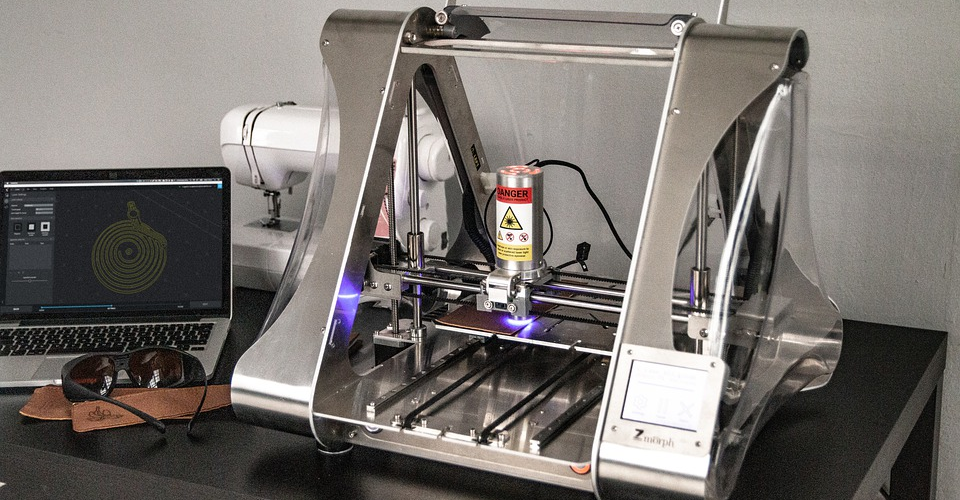

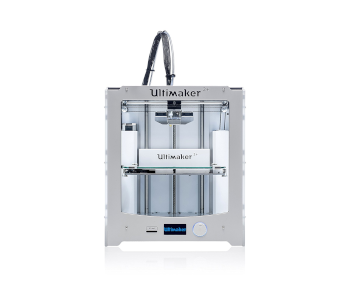

3D printer – A broad term that refers to any machine that recreates a physical 3D model from a digital file. 3D printers are based on the concept of additive manufacturing and create the physical object layer by layer through various means. The most common 3D printing technologies are Fused Deposition Modeling (FDM) and Stereolithography (SLA).

3D scanning – The process of constructing digital 3D models using data collected from real-world physical objects or environments. There are several technologies used in 3D scanning, the most common of which nowadays is photogrammetry.

45-degree rule – A fundamental rule in designing overhanging features, the 45-degree rule states that an overhang must be oriented at a maximum of 45 degrees from the vertical axis. Beyond this angle, the feature will have to be reinforced with a chamfer or a support structure.

ABS – Acetonitrile butadiene styrene (ABS) is one of the most commonly used materials for filament-based 3D printing. It is well-known as a thermally stable, chemically resistant, and strong engineering plastic. ABS is also more infamously known for generating toxic fumes during printing as well as a high propensity for warping.

Acetone vapor bath – An acetone vapor bath is one of the most widely used finishing methods for 3D prints made with ABS. This involves subjecting a finished ABS print to acetone vapors in an enclosed container to selectively dissolve imperfection in its surface. This method is preferred as it can result in a perfectly smooth finish with minimal work involved.

Additive manufacturing – Additive manufacturing refers to any manufacturing method where material is deposited layer by layer to create a fully-realized design. This is in contrast to subtractive manufacturing. Additive manufacturing produces less waste but may not have the same level of mechanical strength.

Amorphous – The opposite of crystalline, an amorphous solid has particles that are not arranged in any organized lattice pattern. In simpler terms, this means that amorphous solids are more “free-flowing.” Most plastics used in 3D printing are amorphous.

Anisotropic – The opposite of isotropic (see Isotropic), an anisotropic material is one that exhibits properties that vary in magnitude when measured along different directions. In the case of 3D printing, objects printed using FDM technology are typically anisotropic when it comes to overall strength because of the innate weakness of the layer-to-layer interface.

Bed leveling – The act of calibrating the level of the print bed to ensure proper printer performance and consistent quality. Some printers may have automatic bed leveling features, while others require the user to do it manually.

Belts – Belts translate the rotation of stepper motors to the movement of specific 3D printer components, such as the printhead of an FDM printer. Belts have to kept taut for proper operations.

Binder jetting – A powder-based 3D printing technology, binder jetting printers use a binding agent delivered by a nozzle to bind the powdered raw material together. The finished product typically requires post-processing to strengthen the binding agent.

Blue painter’s tape – A tape typically used by painters to protect the surface that they don’t wait to pain on, blue painter’s tape is used widely as an adhesive aid for FDM-based 3D printing. The special property of blue painter’s tape is that it does not leave a residue on the surface to which it has been stuck to.

Bowden extruder – A type of extruder where the extruder assembly is located away from the hot end and is usually attached to the frame of the printer. This makes the print head much lighter, allowing it to move faster and with fewer errors.

Bridging – The process of creating “bridges” in a 3D printing project. An FDM printer achieves this by stretching the filament across two points of contact. Bridges are typically limited to a length of 5 millimeters before they need to be reinforced by a support structure underneath.

Brim – A brim is a feature that extends the base layer of a model outwards. By increasing the contact area between the build plate and the print, a brim promotes enhanced bed adhesion. A brim is a slightly more conservative alternative to a raft.

Brittleness – The property of a material that makes it break or fall apart instead of deforming. Brittle materials are typically rigid and inflexible.

BuildTak – A brand of specialty 3D printing surfaces designed for FDM printers. BuildTak improves be adhesion for just about any filament type and can be used with heated print beds. It can be reused for up to 250 hours of total printing time.

Build plate – The part of the 3D printer where the actual project is built on. The build plate is alternatively called the print bed.

Build time – The total time it takes for a 3D printer to finish a single project. Most slicer software will provide an estimated build time once the parameters have been set.

Build volume – The maximum volume of a project that can be made in a specific 3D printer. The build volume of a 3D printer model is one of its most critical specs.

CAD – Computer-Aided Design is a general term that refers to the method, technology, and software used to create 2D or 3D designs using a computer program. The models are generated in a digital format making them easier to share, edit, or reproduce.

CAM – Computer-Aided Manufacturing refers to the technology that translates a 3D model created by CAD to a set of commands for automated manufacturing. CAM is used in 3D printing as well as in numerous other manufacturing methods that use CNC.

Cartesian – A coordinate system based on the x, y, and z axes. Positioning and movement in the Cartesian coordinate system are typically represented as unit distance numbers measured from an established reference point. Most 3D printers use the Cartesian coordinate system.

Chamfer – A design strategy for creating overhanging features that go beyond the 45-degree rule. A chamfer is basically a series of segments that are progressively angled towards the horizontal, with each segment providing support for the next one.

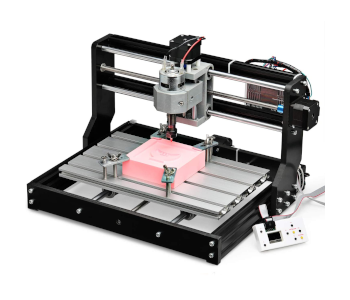

CNC – Computer Numeric Control is the technology that allows for the automation of industrial manufacturing equipment such as mills, lathes, drills, and 3D printers. CNC has proven to be one of the most important technological developments that have given way to the modern manufacturing industry.

Cold end – The part of the 3D printer that feeds the filament into the extruder. It typically consists of a hobbed gear driven by a motor that grabs onto the filament to convey it forward towards the extruder assembly. The term ‘cold end’ contrasts this part of the 3D printer to the ‘hot end’ where the filament is molten by a heating element.

Composite filament – A type of 3D printing filament that combines two vastly different materials, typically for aesthetic purposes. Common composite filaments have a matrix made with PLA in which solid particles of wood, metals, carbon fiber, or ceramics are embedded. Composite filaments are valued for their superior visual appeal but are a little more brittle can abrasive towards standard brass nozzles.

Cooling fan – Fans installed on an FDM 3D printer to help keep its electrical components cool or to cool down the filament which has just been extruded through the nozzle. Cooling down of the filament helps it develop strength quickly, which is useful when building overhangs or bridges.

Cura – A popular brand of 3D printer slicing software developed and maintained by Ultimaker.

Curing – A necessary post-processing step in 3D printing processes that rely on UV light. Curing is done by placing the finished print in an oven with UV light to further strengthen the parts. Curing can also be done over direct sunlight, although this is a much slower alternative.

Delta 3D Printer – A type of 3D printer that has a triangular frame, a print head suspended on three arms, and a circular print bed. Instead of positions based on the Cartesian coordinate system, the position of the print head in a Delta 3D printer is defined by the angle of each of the suspension arms. Delta 3D printers are extremely fast but have limited build volume.

Desiccant – A substance that readily absorbs moisture and promotes dryness in its environment. Silica gel is the most commonly used desiccant, but activated charcoal, zeolites, and calcium chloride are also quite popular. In 3D printing, the desiccant is used to keep filaments dry during storage and transportation.

Direct drive extruder – An FDM 3D printer configuration where the cold end and hot end are integrated into the print head. This simple construction makes troubleshooting easier and makes deformation of the filament less probable. However, it also makes the print head quite heavy and prevents it from moving around quickly.

DLP – Digital Light Processing, a 3D printing technology that also uses UV light for photopolymerization. The main difference of DLP from SLA (see SLA) is that it projects a whole illuminate plane on the resin, thus forming an entire layer all at once. This makes DLP faster, although SLA prints have fewer printing artifacts.

Dual extrusion – An FDM 3D printer feature that allows for 3D prints made with two different filaments. This is handy for projects that need to combine different colors or different materials, as well as for printing support structures with special dissolvable filaments.

Elephant’s foot – A common error in FDM 3D printing characterized by a flared base layer. This is a distortion typically caused by a print bed that is set too hot. This makes the base layer too soft to support the weight of the rest of the print.

End stops – Switches found on the endpoint of each axis of movement of a 3D printer. When the end stops are tripped, it means that the print head has moved to the maximum position for that particular axis. End stops are also useful for the print head to find its home or beginning position at the start of a new project.

Extruder – The extruder is the entire assembly of components in an FDM printer that controls the feed rate of the filament and moves it forward toward the hot end. A 3D printer extruder can have different configurations (see Bowden Extruder and Direct Drive Extruder) but typically have three basic components: the stepper motor, the drive gear, and the idler.

Extruder motor – The motor that rotates the drive gear of the extruder to move or retract the filament. The extruder motor is typically a stepper type (see Stepper motor) which allows for more precise granular control of rotation

FDM – Filament Deposition Modeling, currently the most popular technology used in 3D printing. As the name implies, this 3D printing technology relies on layer-by-layer deposition of molten filament on a build plate according to a model.

Feeder – An alternative term for an FDM 3D printer’s feeding mechanism for the spool (see Cold End).

FFF – Fused Filament Fabrication. This is merely an alternative term for FDM.

Filament – The form of raw material used in FDM-based 3D printing. The conventional filament is typically made of a thermoplastic that can be molten down to a semi-fluid state and solidify again upon cooling. Delivery of material via filament provides a form that is consistent, inexpensive, and easy to handle.

Fill density – The density of the infill structure that will be printed inside a semi-hollow outer shell. Adjusting fill density is a way to conserve filament use and reduce build time while providing mechanical support to the finished 3D print.

Frame – The casing or outer chassis of a 3D printer, the frame is responsible for keeping all a printer’s components aligned and reducing vibration during operations. Most frames of 3D printers nowadays are made of stainless steel or aluminum, although inexpensive models with acrylic frames are also quite common.

Glass transition temperature – The temperature at which a rigid solid material starts to become soft and semi-rigid. Take note that the glass transition temperature is not equivalent to melting temperature in most cases, at least in the context of 3D printing.

Gluestick – A common option for adhesive aid on 3D printer print beds. Gluestick is preferred by many because of how inexpensive it is and how easy it is to apply.

G-code – The standard programming language for machines that use CNC, including 3D printers. A G-code is basically an algorithm that lists out commands for the machine to follow. It is a highly rudimentary programming language with no variables or logic functions. G-code is generated automatically by CAM (see CAM).

Hairspray – A common option for adhesive aid on 3D printer print beds. The advantage of hairspray is that it applies a nice thin coating and remains stable even at high temperatures. However, the application of hairspray can be quite messy and needs to be done away from the 3D printer.

Heat creep – A phenomenon that happens in FDM printers where heat from the hot end conducts backward, thus expanding the extent of the melt area. When left unchecked, this could result in extrusion problems.

Heat sink – A part of the hot end that prevents heat creep (see Heat Creep). A heat sink is a piece of conductive material located just before the heating element which draws heat away from the filament. A heat sink fan helps to disperse away this excess heat.

HIPS – High Impact Polystyrene, a filament material typically used to print support structures. The unique characteristic of HIPS is that it dissolves in limonene, making removal of supports a lot easier. Due to its printing temperature, HIPS works best with ABS.

Hot end – The part of an FDM 3D printer that is responsible for melting the filament. It consists of the nozzle, a heating block, a thermistor, and a heat sink.

Hygroscopic – The property of readily absorbing moisture. 3D printing filaments are notoriously hygroscopic and must be stored in airtight containers with desiccant.

Idler – A component of the extruder assembly that sits opposite the extruder drive gear. The idler provides a surface against which the filament will be held, allowing the drive gear to “grab” the filament. Idlers are typically made of PTFE to reduce friction.

Infill – The material inside the outer shell of a 3D print. Infill density and pattern can be customized to strike balance between the mechanical strength of a 3D print, how much filament the project consumers, and its total build time. A completely solid 3D print has 100% infill.

Isotropic – This describes a property of a material that is equal when measured across different directions in each axis. The opposite if anisotropic (see Anisotropic).

Kapton tape – A common option for adhesive aid on 3D printer print beds. Kapton tape is a polyimide film that is highly valued because of its thermal stability. Like blue painter’s tape (see Blue painter’s tape), Kapton tape does not leave a sticky residue upon removal.

Layer – The main building element of additive manufacturing, each layer of a 3D printed object corresponds to a single slice of the reference 3D model. Each layer is completed before the nozzle or the print bed moves to give way for the building of the next layer.

Layer height – A setting in the slicer software, the layer height determines the thickness of each layer. Thin layers are better for reproducing highly precise details but will increase build time. Thick layers help in finishing a project faster but may result in loss of detail. The layer height is also a function of the nozzle diameter (see Nozzle).

Limonene – A liquid hydrocarbon derived from oils extracted from citrus fruit peels. In 3D printing, limonene is typically used as a solvent to dissolve support structures made from HIPS filament.

Lithophane – An embossed photo on hard material that reveals its details when viewed against the light. Variations in thickness interact with the light to show the representation of the photo to which the lithophane has been referenced to. A lithophane is a great project for 3D printing.

Melting point – The temperature at which a solid material turns into liquid. In the context of 3D printing, filament material needs to be heated to its melting point to allow for extrusion through a narrow nozzle.

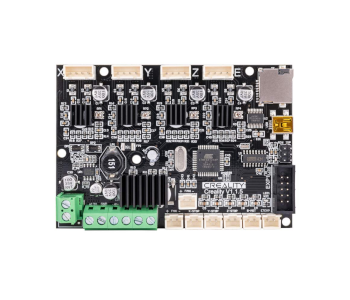

Motherboard – Also known as the mainboard or controller board, a 3D printer’s motherboard contains all the controllers that are essential for the printer’s operations. This is where commands from the G-code are executed and data from the sensors are received for closed-loop feedback.

Nozzle – The exit point for the molten filament in an FDM 3D printer. The stock nozzle of a 3D printer can be swapped for nozzles with different diameters (see Nozzle diameter) or made of different materials (see Wear-resistant nozzle).

Nozzle diameter – The diameter of the opening of the nozzle in an FDM 3D printer. The stock nozzles of most 3D printers have a diameter of 0.4 mm. For high-resolution prints, this can be reduced to as small as 0.25 mm. There are also larger options (up to 0.6 mm) that reduce build time for low-detail models.

Nylon – A 3D printing filament that exhibits superior durability and resistance to wear and tear. Nylon prints at high temperatures and is prone to warping.

OBJ – A file format for 3D models that preserves a higher level of detail compared to STL (see STL). It supports precise mesh surface encoding which results in smooth surfaces at any viewing scale. As a consequence, OBJ files are also much larger in terms of file size.

Overhang – Any feature in a design that does not have support structured reinforcing it underneath. Overhang features tend to collapse under their own weight if they are oriented more than 45 degrees from the vertical. To avoid this problem, a support structure can be placed below the overhang.

PAEK – Polyaryletherketone, a chemical group under which PEEK (see PEEK) and PEI (see PEI) are classified under. PAEK polymers are known for being exceptionally strong and stable under high-temperature conditions. They also do not emit toxic fumes when heated.

PEEK – Polyether Ether Ketone, a high-performance specialty filament for FDM 3D printing. PEEK prints at very high temperatures (up to 400 C) and is very expensive. In return, it is one of the most thermally and chemically stable 3D printing filaments available today.

PEI – Polyether Imide, a high-performance filament material used in FDM 3D printing. PEI is characterized by very high tensile strength, thermal stability, and chemical stability. Just like PEEK (see PEEK), PEI is also a lot more expensive than the usual 3D printing filament.

PETG – Glycol-enhanced polyethylene terephthalate, a 3D printing filament that is often described as a combination of the best properties of ABS and PLA (see ABS and PLA). PETG is a durable and thermally stable material that is more resistant to warping and does not emit toxic fumes.

Photopolymer – A resin that changes properties when exposed to light, particularly in the frequency of ultraviolet (see UV light) or visible light. In the context of 3D printing, photopolymers are used as raw material for Stereolithography (see SLA).

Pillowing – A 3D printing error most commonly exhibited by holes or uneven surfaces on the top-most layer of a 3D print. Pillowing is caused by the warping of the top layer and can be addressed by increasing the infill or cooling down the top layer rapidly.

PLA – Polylactic acid, one of the most popular filaments used in FDM 3D printing. PLA is particularly popular for beginners as it is very easy to handle, does not warp, and prints at relatively low temperatures. It is also derived from plant matter, making it sustainable and 100% biodegradable in its base form.

Polar 3D Printer – A type of 3D printer that uses a Polar coordinate system (see Cartesian coordinate system). Polar 3D printers are quite rare and are characterized by a rotating build platform and a print head that moves up and down. They are very power-efficient but are still too specialized for mainstream 3D printing use.

PolyJet – Short for ‘polymer jetting,’ this is a 3D printing technology that uses the principle of material jetting technology. PolyJet printers have a set of nozzles that precisely deliver drops of photopolymer resin on a build plate which are almost instantly cured by an array of UV lights. PolyJet printers are usually used for 3D printing projects that require a very high level of detail.

Post-processing – Any treatment of the 3D print after the printing process is considered part of post-processing. This includes sanding, polishing, painting, and gluing together of parts that were printed separately.

Print bed – An alternative term for a build plate (see Build plate).

Print speed – The speed at which filament is extruded, typically expressed in mm/sec. This is set in the slicer software and can be further refined into different settings for the bottom layer, top layer, outer shell, and infill.

Printing temperature – The temperature setting of the heating element of an FDM 3D printer. The print temperature is set based on the filament being used and affects many aspects of the process including the rate of extrusion, layer-to-layer adhesion, thermal stress accumulation, and product quality.

PTFE liner – A PTFE liner is found in the entry point to the hot end assembly of an FDM 3D printer. The liner is made of PTFE (Teflon) to reduce friction. Due to heat creep, the PTFE liner in a hot end needs to be replaced periodically.

PVA – Polyvinyl alcohol, a filament material used in FDM 3D printing primarily to print support structures. PVA dissolves readily in water, making removal of support structures after printing very easy. Based on its printing temperature, PVA is most compatible with PLA (see PLA).

Raft – A feature that places an entire “sacrificial” layer underneath the base layer of a model. Its purpose is to prevent warping of the main model and improve bed adhesion. Although effective, a raft also consumes a significant amount of filament.

Rapid prototyping – The process or technique of creating scale models of physical parts. Through the help of 3D modeling and additive manufacturing methods like 3D printing, this can be done quicker than through more traditional manufacturing methods.

RepRap – Short for ‘replicating rapid prototyper,’ this is an open-source project that started in 2005 with the goal of developing a low-cost 3D printer. Through several generations, the RepRap printers were successful in reproducing parts identical to their own.

Resin – The form of raw material used in SLA-based 3D printing. At its raw form, the photopolymer resin is in a highly viscous liquid form which solidifies rapidly when exposed to UV light.

Resin tank – The containment for the resin used in SLA 3D printers. The build volume of an SLA printer is highly dependent on the volume of its resin tank.

Resolution – In 3D printers, resolution refers to the smallest size of features that it can reproduce. The resolution of a 3D printer in the z-axis may vary from its resolution in the x and y axes. The size of the nozzle and movement of stepper motors also play a role in determining a 3D printer’s resolution.

Retraction – A technique for pulling back a portion of the filament. This is possible through the reverse rotation of the extruder drive gear. Retraction is typically done to relieve pressure on the nozzle and avoid over-extrusion problems.

Seam – The boundary between two successive layers or the line at which they meet. Layer seams are much more visible in prints made via FDM than with SLA.

Shell – The exterior walls at the side of a 3D print.

Shell thickness – The total thickness of the outside walls of a 3D print. The shell thickness setting has to be a multiple of the nozzle diameter.

Skirt – A thin line of filament printed just outside the shell of the first layer of a 3D print following its perimeter. The primary purpose of a skirt is to prime the extruder and avoid errors when the printing of the actual base layer commences. A skirt also helps in slowing down the cooling of the base layer by acting as an insulator against the cold outside air.

SLA – Short for Stereolithography, this is one of the earliest forms of 3D printing technology ever created. SLA uses a photopolymer resin as a raw material that hardens almost instantly upon exposure to UV light. The UV light hits the build plate at patterns determined by the slicer software to build the 3D model layer by layer.

Slicer software – A slicer is a program that acts as the CAM software for 3D printing. What it does is that it separates a 3D model into slices and generates the appropriate G-code to reproduce each slice as a layer in the 3D printer. Features such as support materials, rafts, skirts, and brims, can also be added to a project through a slicer software.

SLS – Short for Selective Laser Sintering, is a 3D printing technology that uses a high-powered laser beam to fuse powdered raw materials together. The material in this case can either be metal, plastics, ceramics, or glass. Although versatile, SLS is limited by high capital costs and excessive waste generation.

Soft pull – A process for removal of blockage inside a clogged nozzle. It is done by heating a filament inside a nozzle to its glass transition temperature inside the nozzle and pulling it out once it has cooled down. A soft pull can be done regularly as part of nozzle maintenance.

Splitting – A 3D printer error that results in the visible separation of layers in a finished print. It is primarily traced to poor layer-to-layer adhesion due to improper layer height or printing temperature settings.

Stepper motor – A type of motor in which rotation is divided into discrete and equally spaced “steps.” This allows for precise control of its speed of rotation and positioning. Stepper motors are found in just about all the moving parts of a 3D printer such as its extruder and print head assembly.

STL – A native file format used for 3D models created in the stereolithography CAD software platform. It is widely used in 3D printing because it is a very lightweight file format. STL files achieve this by “simplifying” surfaces as an array of tessellated triangles. Although STL files do not have as much detail as OBJ files (see OBJ), they are highly preferred for sharing 3D models.

Stringing – A problem in FDM printing manifested by the formation of very thin “strings” of filament. This is a common sign of over-extrusion but can also be caused by molten filament oozing out of the nozzle while it is traveling.

Stripping – This happens when the hobs of the extruder drive gear bite into the filament and literally strip off the material. This filament material gets stuck in the hobs, thus preventing the gear from doing its main function. Stripping will lead to extrusion problems and can only be remedied by opening up the extruder assembly and manually cleaning the hobbed gear.

Subtractive manufacturing – A manufacturing method where the final part is cut down from a solid block of the source material. Common examples include milling and lathing. Subtractive manufacturing results in stronger finished parts but inevitably generates a lot of waste.

Supports – Also commonly known as support structures, these are structures added to a 3D print to reinforce bridges or overhanging features. Supports can be easily added through the slicer software and can either be tree-type or lattice-type.

Tensile strength – A property of a material that determines how much stress it can withstand. The tensile strength can be further sub-divided into the yield stress and ultimate tensile strength. The former refers to the stress under which the material undergoes plastic deformation, while the latter refers to the stress at which the material will fracture.

Thermal stress – The internal stress generated in a material as it changes in dimension as a reaction to changes in temperature. The accumulation of thermal stress in 3D prints as they cool down is what causes warping.

Thermistor – A ‘thermally sensitive resistor’, a thermistor is an electrical component that has a resistance value that changes with temperature. It is used to measure the temperature of an FDM printer’s hot end and is usually located right next to the heating block. Feedback from the thermistor is used in a closed-loop feedback system to allow for precise temperature control.

TPU – Thermoplastic Polyurethane, a common filament material used in FDM 3D printing. The distinguishing characteristic of TPU is its rubber-like elasticity, making it ideal for products that need to withstand heavy deformation.

Travel speed – The speed at which an FDM printer’s print head travels across the x and y-axis when it is not printing, typically expressed in mm/sec. Increasing travel speed can reduce build time but also has the risk of the print head overshooting its target destination, resulting in quality issues.

Under-extrusion – A common problem in FDM 3D printing where not enough filament is being extruded. This can result in missing layers, overly thin layers, or random holes in the print. There are a lot of possible reasons for under-extrusion including sub-optimal printing temperature, filament stripping, or a clogged hot end nozzle.

ULTEM – A brand of PEI (see PEI) filament owned by GE’s Plastic Division. Practically all PEI filaments used today carry the ULTEM brand. The ULTEM 9085 filament has received certification for use in parts for civil aircraft.

UV light – Ultraviolet light, also known as “black light. More specifically, light with a wavelength of 10 to 400 nm. UV light is used in 3D printing for the curing of photopolymer resins. UV light can also cause the breakdown of certain filament material used in FDM 3D printing.

Viscosity – A property of a fluid simply described as its “resistance to flow” and more colloquially as its “thickness.” In FDM 3D printing, viscosity plays a role in ensuring the consistent flow of molten filament through the nozzle and onto the build plate.

Warping – One of the most common problems encountered in 3D printing, warping is the result of thermal stress accumulation which causes deformation of the material. Aside from causing dimensional inaccuracy, warping can also result in poor bed adhesion. Some 3D printing materials are more prone to warping than others.

Wear-resistant nozzle – Typically made of either stainless steel or hardened steel, this is a nozzle type preferably used when printing with an abrasive filament. The drawback of these materials is that they have poorer thermal conductivity compared to the stock brass nozzle.

Final thoughts

With more than 100 terms in this glossary alone, it’s pretty clear that a thorough knowledge of the terms used in 3D printing is an essential part of thriving in this field. We still have probably missed a few terms and we expect to be constantly updating this list when more come to mind. Are there terms you would like to know about? Let us know about them in the comments section.