Plastic Pellets for 3D Printing: What’s the Point?

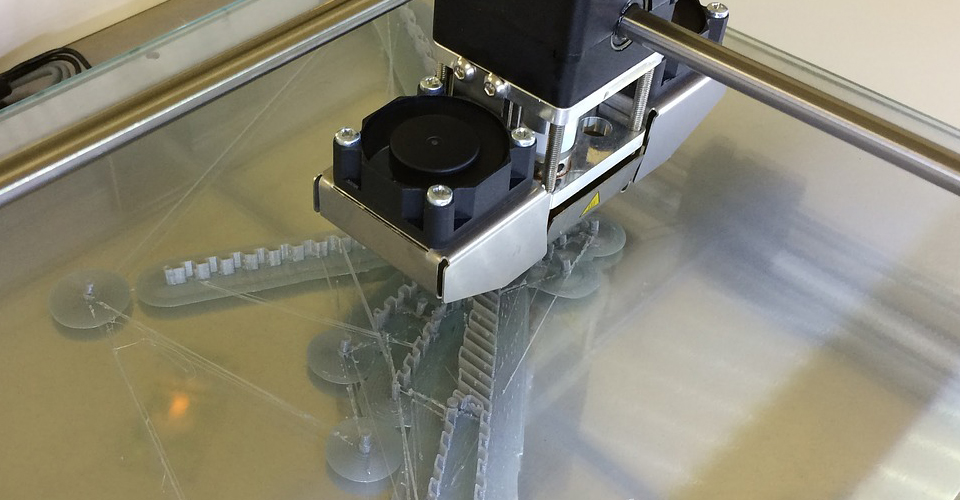

Among mainstream observers, 3D printing almost exclusively refers to printing using Fused Deposition Modeling (FDM) technology. There are several good reasons why FDM has become the most popular mode of 3D printing: it’s cheap, uses simple technology, and is easy to learn. In FDM printing, the starting material is typically plastic filament, which is fed into an extruder and a hot end nozzle. The melted filament is then laid down on a build platform, the print head moving according to the design you have loaded to the printer.

The process has been so firmly established that any deviation to how it’s normally done feels jarring. This makes the idea of FDM printing using plastic pellets – and not plastic filament – quite interesting. What’s the point of using plastic pellets? Are there any benefits to it?

What are plastic pellets?

Plastic pellets, sometimes called nurdles, are very small, bead-like, and compact pieces of solid plastic that are melted and formed into all the plastic products that we encounter every day. They are essentially the “raw” form of plastics before they are converted to more useful shapes.

Why use plastic pellets?

Here’s the thing about plastic pellets. All plastic products, from your humble plastic bag to the filament you feed into your 3D printer, started out as plastic pellets. Plastic manufacturing facilities and plastic recyclers typically make plastic pellets by cooling the liquid resin solution, forcing it into an extruder and cutting it into regular shapes.

The plastic pellets are then further processed so that they can be more useful. For instance, they can be re-melted and fed into an injection molding machine to form butter tubs and other food containers. They can also be fed into a film extrusion machine to create plastic sheets, wraps, and bags.

In the case of 3D printing filaments, the pellets are simply re-melted and re-extruded. During the process, various compounds can be added to the melted plastic resin to enhance its properties. These compounds can range from simple dyes to add color to the filament, or fine solid particles like wood or carbon fiber to create composite filaments. In any case, all filaments start with the most basic form of the plastic, such as ABS or PLA pellets.

Why is using plastic pellets directly for 3D printing a good idea? By bypassing the process by which pellets are converted to filament, a 3D printing professional should be able to create prints at a lower cost. In theory, a plastic filament can cost up to ten times more expensive than its base plastic pellets of the same weight.

But how about the additives that manufacturers put into 3D printing filaments? Nothing is preventing you from adding the same components into the plastic pellet. There might even be a potential of coming up with your own brand of composite filament.

Is there an FDM printer that can print with pellets?

The biggest problem with the idea of 3D printing directly from plastic pellets is that there just aren’t many 3D printers that support it. Right now, commercially available pellet printers are only used for large manufacturing systems. At their scale, these printers are cost-prohibitive and impractical for casual users. There is a little bit of comfort in knowing that the technology already exists – it only needs to be miniaturized and replicated in a more commercial scale.

The good news is that efforts are already underway to make pellet printing technology more accessible. Gigabot X is currently under development by the same team that created the large-scale Gigabot 3D printer. The Gigabot X works by using an extrusion screw in place of hobbed gears that can transport molten filament material to the printing nozzle. This extrusion screw extends to a modular hopper that can accept different plastic pellets.

According to the Gigabot X development team, the pellet-fed Gigabot can print a project 17 times faster than a standard filament-fed printer. In the future, the Gigabot X is being envisioned as an affordable, large-scale 3D printer that can accept recycled and pelletized plastic.

A working prototype of the Gigabot X has already been created, and you can show your support to the team by being an early adopter. It will cost a lot, of course – nearly $10,000.

How about making your own filament?

If the technology to print directly from pellets isn’t commercially available yet, how about making your own filament from plastic pellets? This is a technology that is already a bit more developed, thanks to the fellows at Filabot. The Filabot Extruder is a product marketed as a way to create 3D printing filaments from plastic waste, like that ruined Benchy you made when you first fired up your 3D printer.

The technology behind the Filabot Extruder is quite simple: small pieces of scrap plastic are fed into a hopper, melted inside the heating zone, and extruded through a nozzle by an extrusion screw. You can even buy Airpath cooler and spooler attachments to make sure that the filament you get is as good as new.

Although the Filabot Extruder was meant to recycle scrap plastic, there’s no reason that it also cannot be used to turn plastic pellets into filament. However, this adds more steps to the 3D printing process. A Filabot Extruder is also very expensive, costing nearly $10,000 without the attachments.

Other problems of printing with pellets

Although commercial-scale adoption of the technology to print directly from plastic pellets seems to be on the horizon, we can still foresee several problems that early adopters may encounter.

1. Poor metering

One of the biggest benefits of printing with filaments is that you can very accurately control the mass of filament that you are extruding towards the nozzle. Since a filament has fairly consistent dimensions, it’s easy to hit the “sweet spot” where the rate of extrusion and heating is just right. This is something that may be a bit more difficult when using pellets. As you can imagine, plastic pellets packed into hopper will not enter an extrusion screw at a consistent rate. Thus, you may experience over-extrusion and under-extrusion in the same print.

2. Poor homogeneity

Similarly, filaments with additives like dyes or wood particles have a fairly consistent composition throughout the length of the filament. One of the oft-touted benefits of pellet printing is that you can make your own filament using just base plastic pellets like PLA or ABS. However, putting in your own additives can become a hit or miss proposition. You might end up with a print that has patches of color, or a print with structural integrity because certain spots have way too much wood particles.

3. No retraction

Perhaps the biggest limitation of not using filament for 3D printing is the loss of the ability to retract the printing material while the print head moves. As you may know, hobbed gears can retract solid filament to ease the pressure off the molten filament at the hot end extrude. This is done to avoid stringing issues, especially if there are huge gaps in the design. It’s unclear how a pellet printer with an extrusion screw can replicate this crucial feature.

Final thoughts

Is pellet printing the future of FDM technology? From what we see, this “revolution” in 3D printing is not something that is bound to happen soon. 3D printing using filaments became popular because they are easy to handle, consistent, and predictable. They are also quite cheap, although plastic pellets can easily beat them in the price department.

The efforts of inventive manufacturers to come up with commercial-scale technology for pellet printing are highly appreciated, and we look forward to their success. However, we can foresee a lot of problems that pellet printers will encounter. At this point, we cannot see how pellet printers can perform as consistently and predictably as filament printers. This lack of control is perhaps the biggest hurdle that pellet printers need to overcome before people can be convinced with the technology.

The potential benefits of printing directly from pellets are huge. The process will be faster, the raw materials will be cheaper, and a lot of customization options will open up. Pellet printers may pave the road to creating 3D printer objects from recycled plastic, which can empower the 3D printing industry to play a role in minimizing solid waste. We hope that these benefits will be enough to incentivize further work on making better and cheaper pellet printers.