3D Printing Tree Supports – What They Are and How They Work

Supports have often been described as a necessary evil in 3D printing. They use up more filament, are difficult to remove, and make printing times longer. However, you probably cannot do without them, especially if you like printing very complex models.

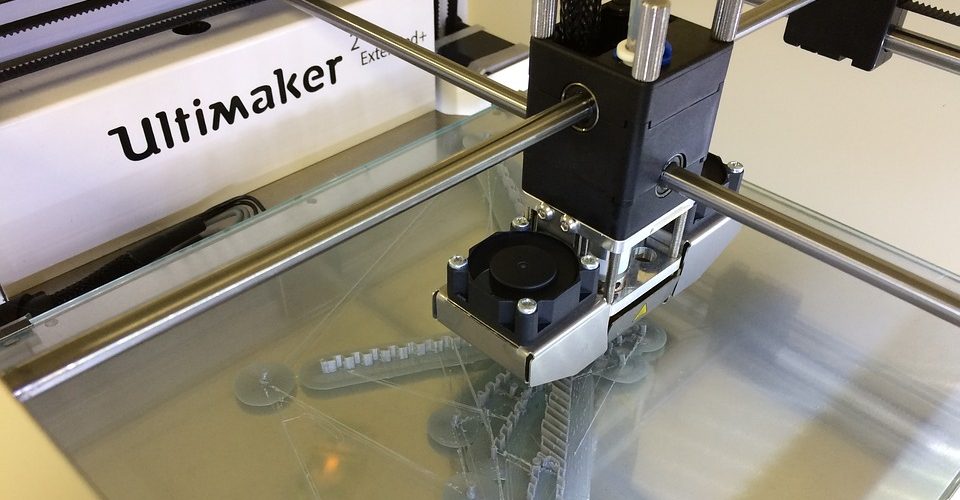

With this in mind, it is easy to see the massive room for improvement in designing and generating supports for 3D printing. One of the more unusual options available in Ultimaker Cura is the tree support. What exactly is a tree support and what does benefits does it offer? Is it better than other support options?

Why are supports needed?

Supports are a natural consequence of the very concept of 3D printing. Since 3D printed objects are built layer by layer, it is almost unavoidable that some of the features in a model tend to become overhangs. Without any intervention, these features will be printed on thin air, instantly ruining your project.

Slicers can be set up to automatically add supports to the overhanging features of a model. By enabling this option, structures will be printed just below these features to prevent them from collapsing. There is a great degree of freedom in choosing exactly how much and what type of supports you want to print.

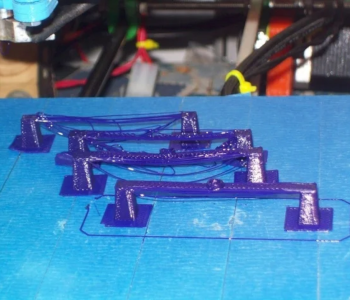

As essential as they are, printing with supports usually comes with a great deal of inconvenience. The fact that you end up using more filament and lengthening the printing time is the least of the problems related to supports. After printing, these supports need to be removed. This step is harder than it sounds, and is a constant source of frustration for many 3D printing hobbyists.

Prints can get damaged if support removal is not done properly. Even with best efforts, supports often leave imperfections on the surface of the finished print that will have to be sanded smooth. This is especially bothersome in highly complex prints where a huge number or density of supports is necessary.

With all the extra work related to support removal in mind, it is understandable that a lot of users tend to spend a lot of time tweaking and refining supports in their slicer software. It is also for this reason that the unconventional tree support has become popular.

What are tree supports?

Tree supports is one type of support offered by the Ultimaker Cura slicer software. As the name implies, the major characteristic of tree supports is that they look like branches of trees. This is more than just aesthetics, though – the unique shape of tree supports offers some unique benefits.

Just like tree trunks and branches, tree supports start thicker at the bottom and continually taper as they grow upward. They are also quite dynamic and can bend and twist around the features of your model. The fact that tree supports can be printed at an angle is one of its more distinct advantages over other support options.

Tree supports started out as “Experimental” support options in older versions of Cura. According to stories, the concept of tree supports came about as a result of an Ultimaker-wide hackathon to develop improvements and optimizations to their current 3D printing technologies. The feature was tweaked and improved progressively until it has become a part of the normal selection for support options.

Much like other supports, Cura also offers ways to customize tree supports. Since the main “trunk” of tree supports can quite hefty, you can control its infill density to reduce filament usage and printing time. You can also adjust the angle of the tree supports, as well as their diameter and placement.

Pros and cons of tree supports

Tree supports are considered by many to be superior to other support types in terms of ease of use and reliability. However, it is still not a good idea to use tree supports for every single project. To assess if tree supports are appropriate for your model, here are the things that it brings to the table, as well as its drawbacks.

PROS:

Less material use

Tree supports were developed primarily to reduce filament consumption in printing supports. It is quite successful in attaining this objective. By wrapping around the features of the model and growing at an angle, a smaller number of tree supports is needed for any given model compared to other support types. It also follows that the increase in printing time because of tree supports is less significant.

Less scarring

The structure of tree supports has them being printed with wide diameters at the bottom and tapering off upwards. This provides maximum stability to the prints while minimizing the contact area with the model. This means that they are also less likely to leave scars upon removal. For this reason, using tree supports is often recommended for models with complex geometries or very fine details.

Easier to remove

Since there is minimal contact between tree supports and the model, support removal is also a lot easier. When done right, tree supports should be loose enough to be removed by hand without leaving any residual material. This may not always be the case, but a case can be made that you’re more likely to have an easier time removing tree supports than you would a lines or grid-based support.

CONS:

Longer slicing time

Tree supports are complex, precisely because they are not straightforward. Depending on the geometry of your model, tree supports may have to bend and twist in several different directions before they come in contact with your model. Due to this complexity, the slicing time typically becomes longer when using tree supports. This can become frustrating if you like making gradual changes to your slicer settings.

This does not mean that you should always use tree supports for all your models. There have been instances where tree supports failed, while more traditional columnar supports yielded better results. The benefits of tree supports typically become more pronounced in models with intricate details and finer overhang features. The flexibility of the design of tree supports make them more adaptable for building around all those intricate details.

There is no hard and fast rule here. It will take some careful examination of your model before you can determine which support is most suitable. If you can make do with simple supports, then our advice is to not over-complicate your situation.

Setting up tree supports

As with any support type, there are parameters that you can adjust in tree supports to make them perform better. You will likely have to do some trial and error before you can set up these parameters in a way that satisfies you. However, you can make better use of your time and filament by understanding each parameter.

Branch angle

The branch angle is the angle at which new branches grow from the main trunk. Keeping this at a low number makes tree supports more stable, but also restricts the range of growth of the tree. If you’re still new to tree supports, we recommend not going beyond 50 degrees to prevent your tree supports from collapsing.

Branch diameter

This setting determines the thickness of branch supports. Thicker supports are more stable, but also use up more material and take longer to print. Take note that the main trunk will always be thicker than the succeeding branches, so it’s not wise to set this at very high values. Keeping this value to a maximum of 3 millimeters should strike a good balance of stability and filament consumption.

Branch diameter angle

This setting controls how much the branch diameter and trunk diameter deviate from each other. At a value of zero degrees, the diameter of the tree supports will be uniform throughout, which is not optimal for stability. Increasing the branch diameter angle will create wider trunks that are more stable, but also take longer to print.

If your model is not particularly demanding of very strong supports, then keeping your branch diameter angle at five degrees or lower is acceptable. You can increase this setting if your model has larger overhanging features up to a maximum of 30 degrees.

Collision resolution

This setting checks for any possible collisions between the tree structure and the model. The value for the parameter refers to the tolerance for collision issues. It is advisable to keep this at a low value between 0.15 to 0.2 millimeters to avoid any potential scarring or difficulties in support removal.

Support placement

If you have used supports, then you know exactly what this setting does. Support placement offers you two options – touching buildplate and everywhere. This setting simply controls whether the supports will be only be built on the buildplate or if they can be attached to the model itself.

Selecting the touching buildplate option is almost always better in terms of ease of support removal. What makes it especially suited for tree supports is the fact that branches can grow at an angle, allowing them to reach otherwise hard-to-reach areas.

However, there are still compelling cases for choosing to build supports everywhere. If you have overhanging features near the top of your model, you can massively reduce filament use by having a tree support built on another part of the model.

Support overhang angle

Another standard support setting, the overhang angle refers to the maximum angle of overhanging features for which the slicer will automatically generate supports. The basic thumb of rule is to set this at 45 degrees, but you can choose to be more conservative by setting this at a lower value. A downside of this tactic is that you will end up with more supports, which means more scarring, higher filament use, and more time spent for support removal.

As with any type of support, tree supports can be adjusted based on your preference for reliability, finish quality, and amount of post-processing work. Each project will work best with a different set of parameters, so it’s more important for you to understand how adjusting each parameter affects the finished product. You may even find that you do not need tree supports at all.

Final thoughts

Tree supports are certainly one of the most innovative features to have been developed for desktop 3D printing in the last couple of years. It fulfills the primary objective for support structures but does in a way that is less obstructive. The fact that tree supports use less filament is also a nice little bonus, especially for those who prefer not generating too much waste from their 3D printing activities.

This does not mean that tree supports are the one-size-fits-all solution whenever you’re working with a model with overhangs. There is a lot that can be tweaked with support structures to make them work best for you. Don’t be afraid of making mistakes in the early stages when printing with supports – everyone goes through them anyway.