3D Printing TV Mounts

Recently we had to mount a TV to a hollow wall and, unsurprisingly, it was more difficult than expected. The supplied dry wall plugs made a nasty mess of the plasterboard and left over-sized holes at each of the mounting points. Despite meticulous preparation of the holes, with progressively larger drill bits, the plugs proved unstable. This meant we couldn’t use the supplied items without removal and then extensive filling. This which would have been both messy and time consuming with no guarantee of success. So we turned to 3D printing and put our new UP Box to work.

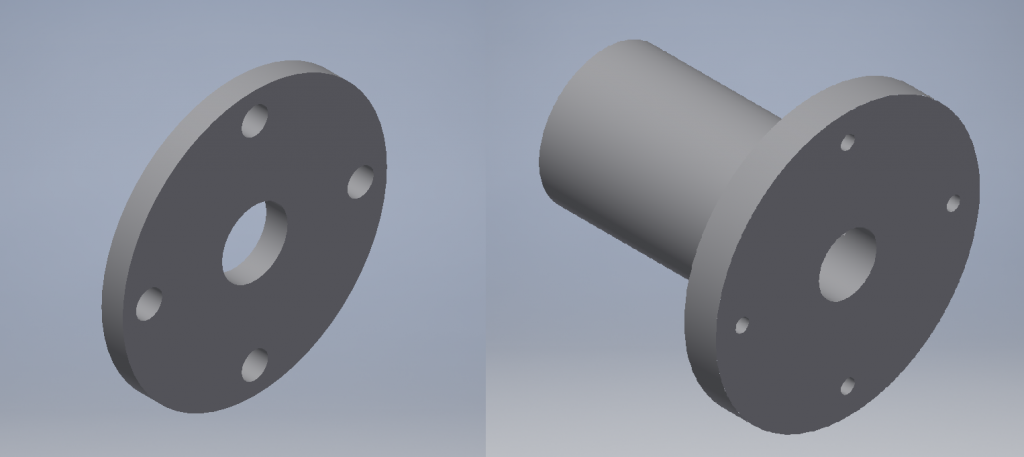

The first step was to model the new mounts in Autodesk Inventor. This took a couple of minutes and consisted of making a few extrusions, placing a hole through the centre, along with four holes around the edge. Four picture hook pins would be used to stop the mount rotating. The original wall plugs used inadequate plastic anti-rotation ridges – which were the cause of our problem. The plasterboard material simply could not provide enough resistance against rotation once an attempt was made to screw in to the plugs. Washers were also added so that the front of the mount would be flush with the back of the TV bracket.

In total four mounts and washers were printed out at a resolution of 150 microns (0.15mm). This took about two hours all up. The mounts were then placed into the holes from which the defunct wall plugs had been pulled out. Our mounts were around double the depth of the wall-board. Each mount was then fixed in place with the picture hook pins. Our design seemed to provide a stable construct for the TV bracket to be mounted. This was facilitated via the screw-in bolts shown below. Of course we must ask – is this arrangement adequate? So far so good and we discern the construct to be nicely dissipating the largely downward weight of the tv through these four bespoke ’emergency’ 3d printed wall mounts. We feel there is a reasonable total surface area from the plugs and they do offer a highly congruent fit within the holes. Our main concern would tend to revolve around anterior/tilting forces on the tv. In such circumstances could their be a tendency for a ‘pull-out’ phenomenon? One solution might be to use an additional dry wall ‘anchor’ to give added security against any forward motion.The television in this case is not particularly heavy but, being based in New Zealand, we are only to aware of earthquake issues and wall mounted items!

Once again 3D printing has proved its worth by providing a working solution for this little problem of ours. The technology has again shown that it can be used for odd jobs around the house. A situation that had turned into a bit of a nightmare wound up as a most satisfying experience. Obviously anyone using 3D printing for mounting items in this way needs to satisfy themselves that the solution they have designed is both safe and stable. We shall continue to monitor our mounts for any signs of pull out or progressive loosening. In the meantime were are off to watch some tv.