Should You be Using ABS or PLA for Your 3D Pen?

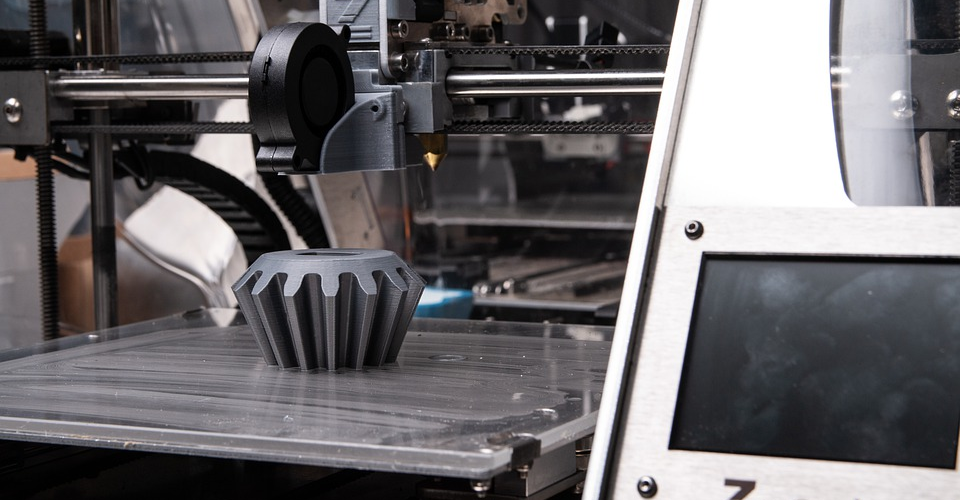

3D pens have been around since the early 2010s and remain fairly popular until today. Fun and easy to use, 3D pens have been used in the fields of art, education, and rapid prototyping as a quick way to come up with simple 3D sketches.

While many 3D pens now have the ability to create objects using a variety of filament materials, there are two that are the most common: ABS and PLA. Just as with FDM printing, the debate between ABS and PLA for 3D pens has been long and drawn-out. Which filament should you be using in 2019? Let’s look at the facts.

What is PLA?

PLA stands for Polylactic Acid, a polymer made from lactic acid building blocks. The lactide raw material used to polymerize PLA is derived from plant materials, making it one of the few plastics that can be manufactured sustainably. Upon breaking down, PLA breaks down again into lactic acid, which is a byproduct that is safe to both the environment and the human body.

Because of its sustainability and biodegradability, PLA has become one of the most commonly used alternatives to traditional, non-biodegradable plastics. The increase of large-scale applications of PLA has made it the bioplastic with the second-highest rate of worldwide production.

Pros and Cons of PLA

PROS:

1. Biodegradable and sustainable

The art of doodling with a 3D pen has unfortunately only become popular at a time when most of the world has recognized our solid waste problem and are working to reduce non-biodegradable waste, such as plastics. There’s also the issue of most plastics being manufactured from petroleum sources, which we know by now is not sustainable.

By using PLA, you can alleviate the guilt of contributing to the global solid waste issue. PLA is 100% biodegradable and made from sustainable raw material. This can be important if you use 3D pens for any professional applications where you tend to go through several models in quick succession. If you use 3D pens for education, sticking with PLA imparts two lessons at the same time: not only do they get to practice their 3D doodling skills, but they also learn the importance of adopting sustainable practices.

2. No odor while printing

Even for young minds who might not yet comprehend sustainability issues, PLA is still the filament of choice because of its toxic-free characteristics. PLA does not emit any toxic gases, or any odor at all when heated. This makes it a much safer alternative to many other filament materials,

While PLA is one of the safest filaments to work with, some level of precaution is still necessary. After all, heating plastic and extruding it through a very small opening can release plastic microparticles in the air, which you or the people in the same room can inhale. Some respiratory protection is recommended, although using a 3D pen in a well-ventilated place will also suffice.

It also bears mentioning that although the base PLA plastic may be non-toxic, some filaments may come with toxic components such as paints. It’s best to check with the manufacturer of your filament is this is a concern.

3. Easy to paint on

Another characteristic of PLA, which makes it great for creative builds, is its remarkable tackiness, which describes how well it sticks to other surfaces. This is great if you want to use a 3D pen to embellish a ceramic bowl or a glass surface. While there are better choices for plastic filaments if you’re looking to maximize tackiness (TPU is much more tacky, for instance), PLA is still an above-average choice that is available virtually anywhere.

CONS

1. Low melting temperature

The low melting temperature of PLA is one of the more distinctive characteristics that also make it a material that’s easy to work with. On the flip side, it also means that PLA prints cannot withstand being exposed to high temperatures. Leaving a PLA print inside a car on a sunny day can be enough to deform it heavily.

This limits the sensible applications of PLA builds. If you’re trying to put embellishments on a ceramic bowl meant to contain hot food or drinks, then you probably shouldn’t consider PLA for your material.

2. Naturally disintegrates over time

We’ve already established that PLA is a naturally biodegradable material, easily one of its most desired characteristics. However, this also means that PLA will degrade naturally, even when simply exposed to the atmosphere. There are a lot of factors that can accelerate how quickly PLA can deteriorate, including sunlight, wind, and particulate matter.

This is problematic if you want to create a prototype or model that you want to still be able to display or use as reference a few years down the line. A PLA build will not last that long. PLA is also not suitable for objects meant to be used in outdoor conditions.

What is ABS?

ABS stands for acetonitrile butadiene styrene, a terpolymer made of three distinct building blocks: acetonitrile, butadiene, and styrene. Each of these monomers influences the chemical and physical characteristics of ABS, making it one of the more complex and durable plastic filaments used in 3D pens.

There are several variants of ABS used across different industries, each with their own unique characteristics. There are a few things, however, that are fairly consistent for any ABS plastic: it has excellent chemical and thermal stability, durable, has good impact resistance, and can be finished to give a smooth and glossy look.

With an impressive set of physical and chemical properties, ABS has quickly risen in popularity as one of the most widely used engineering thermoplastics. In the field of 3D printing, ABS is easily one of the top two most popular filament materials because of its remarkable stability and low price.

Pros and Cons of ABS

PROS

1. High melting temperature

ABS melts at a significantly higher temperature than PLA and most other plastic filaments, which means that not all 3D pens may be equipped to work with it. Despite this small difficulty, many people consider the benefits of this particular characteristic to far outweigh its drawbacks.

This property means that ABS is suitable for high-temperature applications. ABS is great for items that will come in indirect contact with hot food, or items meant to be used or displayed outdoors. Since it takes temperatures of up to 200 °C to melt ABS, your ABS build will stay intact even in the hottest of days.

2. Tough and impact-resistant

Compared to PLA, ABS is a lot tougher and has superior impact resistance. If you need to create objects that need to serve a mechanical function and will go through a lot of wear and tear, then ABS is a very good choice of material.

ABS also has excellent chemical resistance, which has made it very valuable in various commercial and industrial applications. For small-scale 3D art, this property can come in very handy for creating everyday items that might be exposed to a lot of moisture, food, household chemicals, or simply UV radiation from the sun. The sheer versatility of ABS is probably one of the reasons for why it has remained a popular 3D printing filament, despite its setbacks (which we’ll get to later).

3. Can be finished with acetone

A key aspect of the chemical resistance of ABS is that it’s only selectively resistant. Acetone, a fairly common household solvent, dissolves ABS readily. While this could very well be seen as a limitation of ABS, the rapid prototyping industry has leveraged on this property, allowing for acetone to be used as a finishing agent for ABS prints.

A quick application of acetone greatly helps in smoothing over imperfections on the surface of an ABS print, although this is a technique that requires a moderate amount of skill. Acetone is more commonly used in putting together separate ABS pieces of doodles made with 3D pens, acting as a sort of “glue” that melts the plastic together momentarily. Since acetone bonds put pieces of ABS together at a molecular level, the bonds are just as strong as the rest of the material.

CONS

1. Not sustainable or biodegradable

Day by day, consumers are adopting a more environmentally conscious habit when it comes to the products they buy and use. This is a more recent movement which has been growing rapidly in the last couple of years – not that there’s nothing wrong with it, of course. With this shifting mindset, non-sustainable and non-recyclable materials are quickly going out of fashion. As you would expect, ABS is one such material.

All the raw materials used for making ABS are made from non-renewable petroleum products. ABS is also one of those plastics that can take millions of years to fully break down, and even when it does, its byproducts are toxic to plants and animals.

As with other thermosetting plastics, ABS can be recycled to create new plastic products. However, recycling is expensive, and cannot be done an infinite number of times for the same set of plastics. Thus, as long as there are people using ABS, the plastic will continue to be made and, eventually, disposed of.

Admittedly, this has nothing to do with the quality of the material. ABS is an excellent plastic for 3D pens. Your decision on whether to continue using ABS is a matter of personal belief, so it’s really your call on this one.

2. Gives off toxic fumes while printing

ABS is notorious for giving gases that have an obnoxious odor when heated. This isn’t just an irritant, though. Studies have shown that ABS releases styrene, a known carcinogen. Thus, printing with ABS in a place without ventilation is a huge no-no. The problem with working with ABS in 3D pens is that you pretty much have to be up close with what you’re doing, so avoiding all those gases is a bit more difficult.

It’s not impossible, of course, but we suggest wearing respiratory protection on top of working in a well-ventilated room. Suffering for your art is way out of fashion.

Final thoughts

3D pens are incredibly fun for both kids and adults and can be used to create simple doodles to remarkably sophisticated pieces of art. This technology hasn’t been around for very long, so their use cases continue to change and evolve. ABS and PLA being the two most popular filaments for 3D pens is a trend that was likely carried over from the bigger industry of FDM printing, but it doesn’t mean that you need to be restricted to choosing one or the other.

Both ABS and PLA have their good and bad points. ABS is a lot more durable, but PLA is a more environmentally-friendly choice. It all comes down to how you will use your 3D pen, what you hope to create, and your personal beliefs.