What Is the Optimal Ambient Temperature for 3D Printing?

A high ambient temperature is typically favorable for 3D printing. This slows down the cooling of the filament, making it less prone to warping. If a high temperature cannot be maintained, it is advisable to at least have an enclosure around the print chamber. You can also consider actively heating the print chamber if warping issues persist.

Precise temperature control is one of the essential ingredients in creating a perfect 3D printed part. This goes not just for the heated elements of the 3D printer but also for its surrounding environment. How does ambient temperature affect 3D printing? If needed, how can it be controlled?

The effects of ambient temperature

The ambient temperature of the room where you are 3D printing is important because it can become the primary cooling mechanism for the filament. The heated elements of a 3D printer, namely the hot end nozzle and print bed, can reach temperatures between 100 to 250 °C. This creates a huge temperature gradient between the printed filament and its surroundings.

To clarify, cooling is an unavoidable process in 3D printing and one that we rely on for the filament to re-solidify and develop strength and rigidity. However, issues come up when this cooling proceeds too quickly. Rapid cooling results in the accumulation of thermal stress in the material as it shrinks. If this cannot be managed, the thermal stress can be enough to cause the material to warp.

Warping often manifests as curling or lifting of the corners of the first layer from the print bed. When this happens, the print can no longer be salvaged – the physical distortion is not something that can be reversed.

What is the optimal ambient temperature?

Not all filaments are equally affected by cold ambient temperatures. While there are a lot of filaments that tend to warp in a cold environment, there are also some filaments that benefit from rapid cooling. A good example of the latter is TPU, a flexible filament that is ideally cooled down rapidly so that it can develop much-needed rigidity.

On the other end of the spectrum are the filaments that are particularly prone to warping. These are also the filaments that print at very high temperatures. The list includes ABS, Polycarbonate, Polypropylene, Nylon, and a handful of others.

What this means is that there is likely not a single optimal value for ambient temperature. In any case, having to manipulate the temperature of an entire room just for a 3D printer does not seem very practical.

How to control ambient temperature

What we have established so far is that high ambient temperatures are typically favorable for 3D printing. However, there isn’t a single temperature setting that works across all types of 3D printing filaments. There is also the fact that maintaining a constant room temperature is difficult, especially if you’re just in a home or garage workshop.

The best solution is to try and isolate your 3D printer from the rest of the room. This creates a micro-environment that has a temperature that is much easier to control. There are several ways that this can be done according to the requirements of the filament you are using.

Use a heated bed

The most method of temperature control is to print with a heated bed. The goal of a heated bed is to keep the base layer of the print just below the material’s glass transition temperature. The high temperature enhances bed adhesion and keeps the material ductile enough so that the thermal stress can be redistributed.

The limitation of a heated bed is that it only raises the temperature of the first few layers of a 3D print. This isn’t always a bad thing – these are the most important layers of a 3D print, after all. If the ambient temperature of your room isn’t particularly low, then a heated bed might be enough to avoid any warping issues.

Use an enclosure

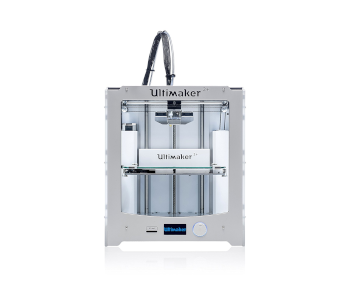

One of the most effective means to create a micro-environment for your 3D printer is to place an enclosure around the print chamber. Right now, there are a lot of desktop-scale 3D printers that come with this type of built-in enclosure. If yours does not, you can easily build a DIY enclosure using inexpensive materials.

An enclosure essentially acts as insulation between the print chamber and the surroundings. This helps maintain an elevated temperature inside the print chamber using the heat from the print bed and the hot end nozzle.

Using a print chamber enclosure is typically enough to address any warping issues, even for the most difficult filaments like ABS and Nylon. An added bonus of printing with an enclosure is that it helps impede the spread of any unpleasant fumes from the 3D printing process.

Place a heater in the enclosure

A heated enclosure is something that is still quite rare in the 3D printing community. As its name implies, this is a type of print chamber enclosure that has been enhanced with an active heating element. The goal is to help maintain an elevated temperature consistently at all points inside the print chamber.

The reason for the rarity of a heated enclosure is the fact that you will likely only need it if you’re printing in an exceptionally cold room or if your filament is particularly prone to warping. Filaments that could benefit from a heated enclosure include Polypropylene or PEEK/PEI.

There are many methods to introduce active heating to an enclosure. Possible options include small space heaters, heating lamps, or even a standard hairdryer. One non-negotiable thing is that a heated enclosure must be equipped with an accurate digital thermometer for monitoring. It is very easy to overheat a print chamber well beyond the glass transition temperature of the filament, resulting in a ruined 3D print.

The appropriate measure for maintaining ambient temperature depends on your specific circumstances. You will need to consider factors such as the tendency of your filament to warp and the actual ambient temperature in the room where your 3D printer has been set up. A single gust of cold wind could be enough to cause warping but overheating the print chamber can also cause your print to deform.

Final thoughts

Controlling the external environment of a 3D printer seems like a monumental task. The good news is that you don’t need to do this. You can simply isolate your 3D printer so that it is contained in its own smaller environment, the conditions of which are easier to control.

The ambient temperature is generally something that will ruin your print if you cannot manage it. The key is to create a hotter environment that will slow down the accumulation of thermal stress in the filament as it cools down.