Automated Post-Processing in 3D Printing – The Final Piece of the Puzzle

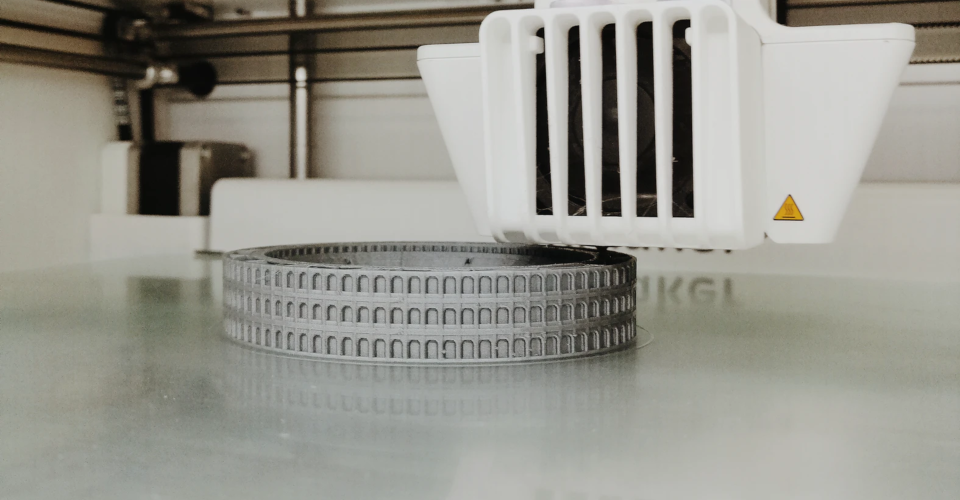

One of the best qualities of 3D printing as an alternative manufacturing method is that it fits seamlessly with most automated processes. 3D printing can run almost automatically for several hours and requires minimal operator intervention.

However, there’s a crucial step in 3D printing that many marketing materials tend to understate – post-processing. The actual post-processing steps will vary depending on the 3D printing material you are working with or the purpose of the piece. In any case, being able to automate post-processing will certainly take 3D printing to the next level of manufacturing relevance.

Why post-processing is necessary

Those who have a shallow understanding of 3D printing may think that it’s some sort of magical machine. You run a 3D model, wait for it to print, and come out with a fully finished piece. This is far from reality. Almost every single 3D printing job will require substantial work in post-processing.

Some experts would even describe post-processing as the “dirty secret” of 3D printing – the step that is kept hidden in the back rooms because they are a departure from the technology’s mainstream image.

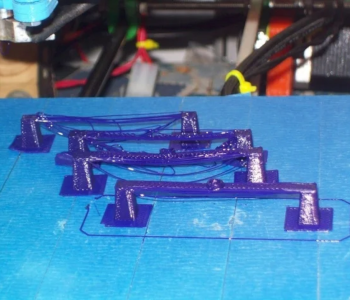

Post-printing is needed because of several factors. Almost all 3D printing methods will require the use of support structures particularly for very complex models. This is a natural consequence of the layer-by-layer method by which 3D printing builds the digital model in the real-world space.

Removal of support structures can take a lot of work whether you’re printing with plastic filament, resin, or metal. Manufacturing firms call this a step that requires tooling. These support structures will have to be cut away and the remaining nubs will have to be smoothed and polished. This is precision work that typically has to be done by hand because the rest of the piece can be easily damaged.

In the case of resin printing, the finished piece needs to be washed and post-cured. For binder-based metal 3D printing, post-processing involves debinding and sintering by exposing the finished print to elevated temperatures.

In commercial settings, the final phase of post-processing is the application of a dye, paint, or a clear coat for protection. This is a fairly easy step but needs to be done at a high level of consistency and quality.

Post-processing of 3D printing is difficult to automate because of its high level of probable failure. In the case of support removal, there may be case-to-case variations that will require skill and a certain level of judgment. Making any design changes will also require that changes be made for the post-processing step. This has proven to be challenging enough to make post-processing the bottleneck of 3D printing a legitimate manufacturing process.

Options for automated 3D printing post-processing

Automation of post-processing of 3D printer parts is still considered an unconventional or novel technology. As such, there is no single approach or method that is considered a standard in the manufacturing industry. These are some of the technology options that exist right now.

1. AI-driven post-processing

By its very nature, 3D printing produces parts that vary greatly in terms of shape, size, and complexity. An appropriate post-processing solution must be able to adapt accordingly. With this end in mind, some automated post-processing systems use a combination of sensors, data processing, and artificial intelligence.

This is the approach being taken by Netherlands-based company AM-Flow. A manufacturing company that focuses on Industry 4.0 concepts, AM-Flow has been developing its automated post-processing technology since 2018 and now offers an entire suite of end-to-end solutions for digital manufacturing.

The system starts by cleaning a 3D printed parts before it is sent to the AM-Vision module. This module is equipped with ten cameras that allow for quick and automated recognition. The part is then sorted and sent to the appropriate departments for additional finishing and painting. One of the best things about this technology is that it is driven by a self-learning AI that speeds up the process.

2. Chemical vapor smoothing

Vapor smoothing is a post-processing option that can be done at home, albeit it is limited only to using acetone for ABS. At least two companies have developed technology that uses the same concept for a wider range of 3D printing materials.

UK-based Additive Manufacturing Technologies have formulated the PostPro3D system for chemical vapor smoothing. This process has been designed to work with parts made from extrusion-based or powder-based 3D printing methods and is compatible with engineering-grade materials like Nylon and ULTEM.

A German company called DyeMansion is taking a similar approach with their PowerFuse S system. This is a closed-loop system that can smooth 3D printed parts made with hard polymers or flexible filaments like TPU or TPE.

3. Support removal

Removal of supports is one of the major requirements of post-processing, especially for prints with complex models and overhangs. US-based PostProcess Technologies has come up with a way to automate support removal at least for prints made via FDM.

The approach of PostProcess is multifaceted. They use a combination of AI-driven software, application of chemicals to aid support removal, and finishing via high flow jet streams. It is a complex and multi-step process, but everything has been designed to be fully automated. The “AUTOMAT3D” platform is particularly impressive as its software can be continuously improved with more “recipes.”

4. Automated depowdering

Powder-based 3D printing processes are some of the fastest in the realm of additive manufacturing. However, it has one crucial post-processing step called depowdering. This is the removal of excess powder from the finished part, including those that are trapped in its internal spaces.

A German company called Solukon has come up with a way to automate this step. Their SFM-AT800 system uses controlled vibrations via a combination of motorized axis rotation and wide-ranging frequencies to methodically remove excess powder from a 3D printed part. It is then fully cleaned using compressed air. The system was designed for powder-based parts made of metals like titanium or aluminum.

5. Multi-step post-processing for metal parts

3D printing with metal may very well be the final frontier of additive manufacturing. If it works reliably, metal 3D printing may render obsolete traditional metalworking methods such as casting and milling.

Although metal 3D printing has minimal tooling requirements, it still needs substantial post-processing. Metal 3D printed parts can still have supports that need to be removed. There is also the fact that metal 3D printing processes are often powder-based, which means that parts need to be depowdered and sintered.

Austrian company Hirtenberger Engineered Surfaces (now acquired by Rena) has come up with the Hirtisation process for metal 3D printed parts. This is a three-step process that involves the removal of support structures, reduction of surface roughness, and high-level polishing to produce an ultra-smooth finish.

According to the company, the Hirtisation process is compatible with just about all metals and metal alloys used in 3D printing and can finish geometries too complex for other automated post-processing methods.

Rena sells this technology in the form of fully enclosed and incorporated modules that can accommodate multiple parts per run. The processing time can vary from 30 minutes to a few hours depending on part size and complexity. The company claims that the modules are so intuitive that there is no special training needed to operate them.

Final thoughts

The potential of 3D printing as an alternative manufacturing method is undeniable. Never before has there been a technology with such a high level of design freedom and practical economics even for low-volume orders. However, the need for post-processing has kept it from becoming fully integrated into automated manufacturing processes.

For 3D printing to become deserving of Industry 4.0 status, its post-processing steps need to be automated. A few companies have already started working on this problem. It’s quite clear that there is still lots of room from improvement at this point.