What is the Best Print Speed Setting for 3D Printing ABS?

An average printing speed of 60 mm/s works well for ABS, but you will have to reduce this by 30% to 50% for the bottom layers, top layers, and the outer shell. Make sure to keep within recommended ABS printing temperatures and print with a heated bed. An enclosure is also a huge help in avoiding warping issues.

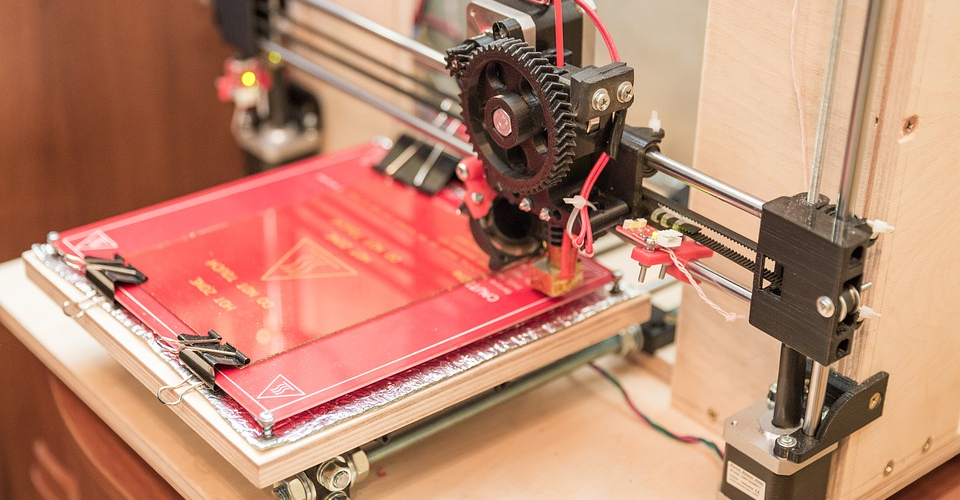

Printing with ABS is considered a difficulty spike for those who are still new to 3D printing. It certainly has its issues, but these can be surmounted with the proper slicer settings. In this article, we will be focusing on one setting in particular – print speed.

What printing speed should you use?

When we talk about print speed, we are actually talking about the rate at which filament is extruded through the nozzle. Although it is an essential parameter, it also does not exist in a vacuum. Getting the right print speed needs to consider other variables such as printing temperature, bed temperature, and cooling rate.

An important aspect of printing speed is that you do not need to stick to a single value for the entire print. There are parts of a 3D printing project that can benefit from lower speeds, while others get by better at higher speeds. Taking advantage of this feature in your slicer is key in perfecting the printing speed settings for ABS.

The default setting for most slicers is 60 mm/s. We find that this works as the average setting even for ABS. However, much lower settings will be needed for the bottom layers to ensure good bed adhesion. Lower speed settings are also recommended for the outer shell to reduce the effects or probability of warping.

For reference, here are the print speed values we recommend:

| Infill speed | 60 mm/s |

| Bottom layer speed | 30 mm/s |

| Top layer speed | 30 mm/s |

| Outer shell speed | 40 mm/s |

Ideal printing performance may still require some deviation from these values, as different ABS filament brands can have different characteristics. When making any changes, it is best to adjust the values in increments of 5 mm/s and check for any improvements.

If you continue to have problems with warping or surface quality, you can consider setting the print speed at lower values for all the sections. Very conservative users have gotten good results when printing ABS with a speed of only 20 mm/s for the entire model. The downside of this approach is that your projects could take an agonizingly long time to finish.

Other parameters to consider

Setting the proper values for print speed will not matter if the rest of your 3D printer isn’t setup for printing specifically with ABS. This material is quite finicky, and you will want to get as many of these elements aligned to get the perfect results.

Printing temperature

ABS is one of the filaments that are considered to have superior heat stability. This means that it also prints at relatively high temperatures – an average printing temperature value of 235 °C works in most cases. However, you’re free to adjust the printing temperature within the range of 210 to 250 °C.

The reason this is important to discuss is that you will want to adjust your printing temperature accordingly should you wish to adjust your printing speed. For instance, maintaining the temperature close to 250 °C and printing at 20 mm/s will likely make the ABS material very fluid-like, making it more likely to run into stringing issues.

To avoid warping, it is usually better to stay at low temperatures and low printing speeds. This will produce less thermal stress as the material cools and shrinks. However, you will want to watch out for signs of under-extrusion when printing at low temperatures.

Bed temperature

A heated bed is absolutely necessary when printing with ABS. This maintains the filament near the glass transition temperature of ABS and helps with bed adhesion. Keeping the ABS material at a somewhat flexible state also allows for thermal stress redistribution that helps prevent warping.

It is also generally advised to apply an adhesive to the print bed when printing with ABS. This helps anchor the base layer to the print bed and counteract the effects of thermal stress accumulation. Worth keeping in mind is to use an adhesive that is stable even at the temperatures of a heated bed.

Enclosure

An enclosure around the print chamber is something that is highly recommended when printing with ABS, if not highly necessary. Having an enclosure around the print chamber helps maintain it at an elevated temperature. This prevents any rapid cooling that can be caused by external drafts or a very cold environment.

Another benefit of having an enclosure is that it controls the release of unpleasant fumes that are released when ABS is exposed to heat. In some cases, exhaust vents on print chamber enclosures can be outfitted with filters to reduce the fumes and any plastic particles that are released to the surroundings.

There are several reasons for why ABS is considered by many to be a difficult filament to deal with in 3D printing. While printing speed is an important parameter for perfecting your ABS prints, it is far from being the only one. It is only by considering all these several variables that you will truly understand how to work with ABS and start getting consistently good results.

Final thoughts

While the average printing speed of 60 mm/s can be used for ABS, setting the slicer to print at very low speeds is a viable strategy if you continue to have problems. You can also try setting the lower speeds only on problematic areas such as the bottom layers and the outer shell.

Should you decide to lower the printing speeds, do not forget to reduce the printing temperatures accordingly. Also as important is to make sure that measures to prevent warping are already in place. These include disabling the cooling fan, heating the print bed, applying adhesive, and using an enclosure. This might take a lot of work but you will find that this is par for the course when printing with high-temperature filaments.