3D Printing with Bronze Filament: Tips, Pros and Cons, and Best Brands

When you 3D print with a material that’s fully plastic, you tend to make something that looks like plastic. Despite all the talk of how versatile 3D printing via Fused Deposition Modeling (FDM) is, it is still pretty limited to using plastic filaments as raw material.

However, some filament manufacturers have gotten around the problem by infusing plastic filaments with distinct solid particles. Bronze filaments are one such example of this innovation. What exactly is bronze filament and how do your work with it? What are the best brands of bronze filaments available today?

What is bronze filament?

Bronze filament is only one of many examples of metal-filled filament. These were designed for 3D printers to come up with projects that simulate the look of real metal while being almost as convenient to use as any other plastic filament.

All metal-filled filaments are made in pretty much the same way. Fine metal powder is combined with a thermoset plastic and extruded into filaments. In the case of bronze filaments, they are typically made with 40% bronze particles and 60% PLA. Almost all composite filaments use PLA as the material for the plastic matrix to make them easier to work with.

When shopping for bronze filament, it is important to make the distinction between “metal-filled” filament and plastic filament that is merely colored with a metallic hue. Metallic colored filament is cheaper and easier to print with but they aren’t going to produce prints with the characteristic luster and heft when made with metal-filled filaments.

Pros and cons of bronze filament

If you’re interested in working with bronze filament, we should warn you that it’s not going to be incredibly easy. The benefits are well worth the extra layer of difficulty, though.

PROS

1. Superior aesthetics

The number one reason for why anyone would print with a bronze filament is that the prints simply look amazing. Bronze tends to have this rustic appearance that will make any display piece pop and catch the attention of just about anyone in the same room.

If you’ve ever wanted a customized figurine or display piece in a gorgeous bronze color displayed in your living room, then 3D printing with a spool of bronze filament would be much cheaper and easier than having a professional metal craftsman do it for you. Superior visual appeal is pretty much par for the course for all composite 3D printing filaments.

2. Better finishing options

The fact that a finished 3D print made with bronze filament has bronze particles embedded in it opens up a whole new dimension of finishing opportunities. While pure PLA can be sanded and finished until it has a smooth finish, bronze-embedded PLA can end up looking like real bronze with the same treatment.

3. Characteristic heft

The presence of solid metal particles in bronze filament makes it a lot heavier than usual. This characteristic translates to the finished print, giving it a certain heft that makes it feel more premium than prints made completely with plastic.

CONS

1. More expensive

Considering that these bronze filaments come with real bronze particles, it’s hardly surprising that they also cost much more than standard PLA filaments. While you can get a 1-kilogram spool of PLA for less than $20, a spool of bronze filament of equivalent weight will probably cost you anywhere between $60 to $100.

When buying bronze filament, keep in mind that the 1-kilogram spool of bronze filament will have a much shorter length compared to a 1-kilogram spool of PLA. The fact that bronze filament is much heavier plays a role in this. This is something to consider if budget is a concern for you.

2. Brittle filament

Embedding any solid particles in PLA makes it lose a lot of its elasticity. This makes bronze filament exceptionally rigid and brittle. When handling bronze filament, you’ll have to be extra careful and make sure that there are no sharp turns over its whole path from the spool to the extruder.

3. Can wear down your nozzle

Bronze may not be the toughest metal around but it’s certainly abrasive enough to accelerate wear and tear on the parts of your 3D printer that come into contact with the filament. This is most apparent in the brass nozzles that come as stock in most desktop-scale 3D printers. A worn-down nozzle can lead to poor detail quality on your prints and an overall drop in consistency.

If you plan on working with bronze filament, you may need to invest in a wear-resistant all-metal nozzle. It would also be a good idea to get a nozzle with a wider diameter (either 0.5 or 0.6 mm would work) to reduce the abrasive forces of the metal particles and to prevent them from clumping up at the orifice.

4. Poor bridging performance

Another consequence of bronze filament being heavy is that it can be very difficult to print overhanging features or cantilevers without them falling apart. If your model has a lot of these features and there’s no way to avoid them, then you may want to consider getting a printer with a dual extrusion system. This allows you to print support structures using a different filament material. PVA (polyvinyl acetate) is a very good option since it prints at about the same temperature as PLA and can be removed simply by submerging the finished print in water.

Working with bronze filament

When tuning your printer settings for bronze filament, there are two key characteristics to keep in mind. The first is that the filament is heavy. Not only does this limit the filament’s bridging capabilities, but it also makes the filament prone to stringing. The second thing to remember is that the presence of bronze particles in the filament makes it a little more conductive to heat. This means that it does not need as much exposure to the heating element, allowing you to print a bit faster than usual.

The recommended printing temperature of bronze filament may vary from one brand to another, but these generally fall within the usual PLA printing temperatures of 190 to 220 °C.

As with PLA, a heated bed isn’t a necessity when printing with bronze filament. However, it will help with bed adhesion if you can print on a bed set at 60 °C. If you are printing with no heat, then a layer of blue painter’s tape of glue stick should do well enough to make the base layer stick. A heated glass print bed will not need any adhesive. PLA generally has no warping or shrinking problems so you shouldn’t have any problems getting the print to stick to the bed.

Since bronze filament heats up really quickly, you can start printing at 30 mm/sec and gradually increase the print speed as long as you don’t see any stringing problems. Blobs and strings can be a problem with a bronze filament because the presence of bronze particles makes it hard to maintain suction on the nozzle. If you run into stringing problems, then you may need to fine-tune your retraction settings.

Since bronze filament has no warping issues, you can use a cooling fan at maximum setting for the whole duration of printing except for the first three layers. Bronze filament produces minimal fumes during printing but it’s still best to print in an area with good ventilation as plastic particles can become aerosolized.

Your finished bronze filament print can be finished using the standard sanding and polishing method for PLA. Start with low-grit sandpaper and work your way up gradually until you finish it with sandpaper in the 600-grit level. It would be best to apply a polish made specifically for bronze such as this Copper, Brass and Bronze Polish from Hagerty. Apply the polishing compound with a soft cloth and continue rubbing until you’re satisfied with the finish.

Best brands of bronze filament

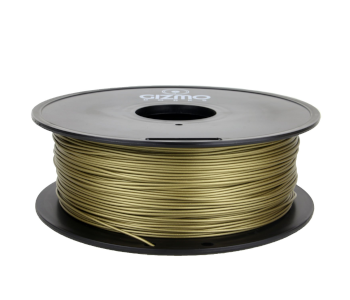

1. Gizmo Dorks Metal Bronze Filament

This bronze-filled filament from Gizmo Dorks is one of the best options in terms of how good the finished prints look. The metallic finish looks great even without any finishing. To make the finished print really shine, you may have to do a bit of sanding and polishing. If that’s too much work for you, then a coat of clear primer also does a good job.

As with other bronze filaments, the Metal Bronze Filament from GizmoDorks also suffers from brittleness problems. It tends to snap at random places and is especially vulnerable to degradation when exposed to humidity. There’s really no going around these challenges aside from being very careful when handling this filament. Considering how expensive this filament is, it would be a tragedy to let it go to waste.

2. ColorFabb bronzeFill Metal Filament

The bronzeFill filament from ColorFabb stands out as being one of the bronze filaments that has the highest amount of embedded bronze particles. With 80% bronze composition, the bronzeFill filament is uniquely heavy and produces distinctly good-looking finished prints.

This is probably the most premium bronze filament that you can get. It’s definitely a more expensive option but there’s nothing that can rival its heft and quality of finish. With a little bit of sanding and polishing, prints made with the bronzeFill filament can look very close to the real thing. You can even rub your print with some steel wool to get that weathered bronze effect.

One issue which you may need to anticipate is that the small amount of PLA in the filament makes layer adhesion a bit of a challenge. You may want to print the bronzeFill filament at the upper end of the printing temperature range and to take it easy on the cooling. As with any other filament, it will take a bit of experimenting to get the best printer settings for the bronzeFill.

3. eSun Bronze Filament

If you’re looking for a relatively low-cost bronze filament just to try it out, then this filament from eSun should be right up your alley. With just 10% bronze powder, the eSun bronze filament is an inexpensive introduction to the world of metal-filled filament printing.

Given how little bronze powder there actually is in this filament, don’t expect it to look like some fancy filament that costs twice as much. It does have this dark yellowish. It is still quite brittle but is a little easier to handle compared to bronze filaments with higher bronze composition. With a little bit of sanding and polishing, you can probably manage to make prints made from the eSun bronze filament stand out.

The roundup

| Material | Bronze Filament (PLA Filament with Bronze Powder) |

| Properties | Aesthetically pleasing, simulates metallic appearance, brittle filament, embedded with abrasive solids, similar printing performance with PLA |

| Applications | Custom jewelry, design or display pieces |

| Printing temperature | 190 to 220 °C |

| Bed temperature | Heated bed not necessary, but heating to 60 °C is ideal |

| Bed adhesion | Glue stick or blue painter’s tape on a non-heated bed; no adhesive needed on a heated bed |

| Print speed | Minimum 30 mm/s, may be higher |

| Cooling? | Cooling set at maximum for the 3rd layer onward; no print bed enclosure |

Bronze filament is a really cool way to show off what your humble desktop 3D printer can do. It’s not an incredibly hard filament to print with because of its PLA base, but it can produce really mesmerizing pieces. If you’ve gotten tired of your usual plastic filaments, then a bronze filament may be a good option to freshen things up.

This is a great article and a must-read when getting into metal filament, one thing I was hoping to see was a recommended nozzle size I’ve been trying a 0.2 hardened nozzle I’m still learning but not much luck with it so I will trying 0.3 next.