What are the Benefits and Limitations of Brushless Motors?

Drones are made up of a lot of small but essential parts that work together to keep them flying. One of the most important of these parts if the motor that drives the rotation of the drone’s propellers and generates lift. In the case of fixed wing drones, these motors allow the propeller to generate forward movement.

If you have been reading about drones or tried looking around at different models, then you have probably encountered the term “brushless motors”. What are these brushless motors and how do they work? Are they better? Read on as we attempt to explain in simple terms the benefits and limitations of using brushless drones.

What are brushless motors? How are they different from brushed motors?

To better understand what brushless motors are and how they work, we need to look at their classic predecessors – the brushed motors. Brushed DC motors have been around for more than a hundred years and was considered the standard motor technology for a very long period. Despite the development of brushless motors, brushed motors remain relevant until today, particularly for low-cost applications.

Brushless motors were first developed in the 1960s and were deemed to be the more efficient alternative to brushed motors. Nowadays, brushless motors can be found in high-end applications and devices such as computer hard drives, electric vehicles, and DVD players. They are particularly preferred for battery-driven devices such as cordless tools because of their increased efficiency, resulting in longer battery cycles.

Both brushed and brushless motors have rotors and stators. As their names imply, the rotor is the component of the motor that rotates while the stator is the component that remains stationary. In a brushed motor, the rotor is located in the center of the motor surrounded by a stator that has a pair of magnets with opposite polarity.

The rotation of the rotor of a brushed motor is driven by a changing magnetic field. This changing magnetic field is made possible by a commutator with brushes that come in contact with a current supply as the central shaft rotates.

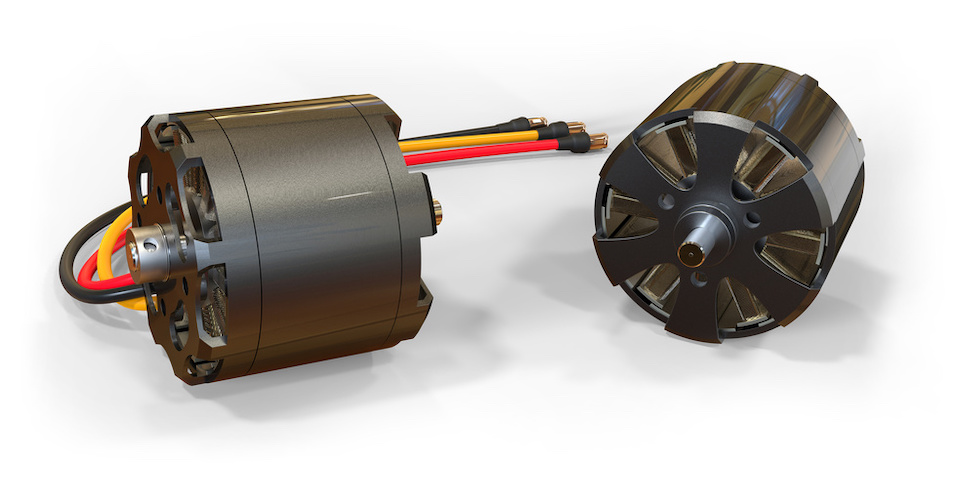

Brushless motors take a radically different approach to generating a changing magnetic field. Instead of a central rotor, the rotor of a brushless motor actually surrounds the stator. In this case, the rotor has a permanent set of magnets which reacts to the changing magnetic field of the stator.

The stator of a brushless drones can be composed of 6 or more pairs of electric coils, each one capable of generating its own magnetic field. As the rotor rotates, the magnetic field of each coil changes in turn, further driving the rotation of the rotor. The regulation of the current to each electric coil is via an electronic speed controller (ESC), so-called because it is capable of controlling the throughput of the entire motor.

On the surface, it is easy to differentiate a brushed motor from its brushless counterpart. Brushed motors are longer and more cylindrical, owing to the increased bulk needed by brushed commutator. They also often have vents, since the constant contact of the brushes generates heat after a while. They have two wires protruding from them, which connect to the positive and negative terminals of a power supply.

On the other hand, brushless motors are shorter and more compact. They have fewer moving parts and the contactless technology means that it generates less heat due to friction. Brushless motors typically have three or more wires protruding from them, and these typically connect to an ESC.

Nowadays, brushless motors can be found in most modern electronics. They are used in industrial-level applications such as aircrafts, medical devices, manufacturing equipment and tools, and robotics. In consumer-level products, they can be found in electric scooters, cordless power drills, DVD players, vacuum cleaners, and washing machines. Despite the persisting popularity of brushed motors, it is not hard to imagine that it is a piece of technology that will eventually be considered obsolete.

Brushless motors in drones

Right now, a vast majority of the higher-end professional and consumer drones use brushless motors. In fact, brushed motors can probably only be found in some of the toy-grade mini-drones.

Improvements in brushless motor design and ESC technology has become a new frontier in innovative drone technology, with companies like DJI and Yuneec coming out with their very own upgrades in recent years. Drone manufacturers are racing to see who can come out with quieter, lighter, and more efficient brushless motors. Improvements in these aspects of motor performance can result in better flight performance and longer flight times, two aspects which many drone pilots deem to be very important.

Advantages of brushless motors

1. Less maintenance

Brushed motors are notorious for having parts that get worn out after a while, requiring frequent dismantling and parts replacement. This is because the brushes of the commutator need to maintain almost constant contact with the terminals of the power source, even as the commutator rotates rapidly. When brushes get worn out and can no longer maintain contact, a brushed DC motor basically becomes useless.

This is less of a problem with brushless motors. In fact, there is essentially no contact between the rotor and stator of a brushless motor, so wear and tear are greatly reduced.

2. More efficient

The constant contact of the brushes with the power terminals of a brushed motor is necessary for it to maintain its rotation. However, the friction that this creates means that a huge portion of the energy generated by the rotational motion is wasted as heat. Generally, the efficiency of brushed motors is limited within the range of 75% to 80%.

On the other hand, brushless motors generate very little heat. There is still some energy loss due to air friction as the rotor rapidly rotates, but this is minimal. Brushless motors are capable of up to 90% efficiency. There are several customization methods for brushless motors that can enhance its efficiency, such as improved ESC algorithms, stronger magnets, and more heat-resistant coils.

3. Longer lifespan

The accelerate wear and tear due to constant contact of the brushes and the energy generated as heat means that brushed motors are expected to break down much sooner than brushless motors. Even for toy drones, it is generally not recommended to operate the brushed motors for longer than several minutes continuously. Without a chance to cool down, heat buildup in brushed motors can easily compromise the integrity of its coils or brushes.

For drones designed to fly for long periods of time, there is really no choice but to use brushless motors. Although there is still some heat generation due to air friction, this is kept at a manageable level. Brushless motors can typically run from 30 minutes to an hour continuously with no problems.

The brushless motors in drones have been shown to last several years with minimal maintenance, as long as they do not get damaged due to a crash. It is possible for the central shaft to get misaligned, or for fine sand and dirt particles to get into the motor mechanism. These conditions will certainly reduce the longevity of a brushless drone.

4. Smaller

Brushless motors have a smaller number of moving parts, giving them the advantage of more compact designs. This is especially important for modern ultra-portable drones that put a lot of premium in maintaining a form factor that is as small as possible.

5. Less noise

Most of the noise generated by brushed drones is due to the contact of the brushes with the power terminals. Despite the use of lubricants to reduce friction, this is a nuisance that is unavoidable when using brushed drones.

Brushless drones are much quieter. Although the rapid rotation of the rotor still creates a characteristic “whirring” sound, it is still a huge improvement to the screeching sound we have come to get used to with brushed motors. More recent developments in ESC design have also resulted in brushless motors that rotate more smoothly, eliminating the rapid “stop and go” motion of older technology.

Disadvantages of brushless motors

1. Expensive

The number one reason why brushless motors have not been as widely embraced as we would have expected it is the fact that it is much more expensive. This price barrier makes brushless motors an unsuitable technology for low-cost toy drones.

Brushless motors have a more sophisticated set of electromagnets. More electromagnets mean more conductive coil material, which is often one of the most expensive components of a motor. Brushless motors also require an additional electric component in the form of ESCs, which drive their prices even higher.

2. Complex wiring

Another huge advantage of a brushed motor is that it can be easily connected to a DC power source for it to run. Based on the concept of how a brushed motor works, all it needs is to be connected to the negative and positive terminals of a power source.

Brushless motors are not so simple. As mentioned, a brushless motor needs to be controlled to an ESC, which controls the flow of current to each electromagnet. Fortunately, pre-fabricated ESCs can typically be purchased bundled with brushless motors. Advanced drone pilots and drone racers are probably familiar with the process of installing their own ESCs and brushless motors to their customizable drones.

Final thoughts

The ability to convert electrical energy to rotational motion is one of the greatest technological developments of our time, a discovery that has gave birth to many aspects of modern technology as we know it. Brushed motors have reigned supreme for close to a hundred years, but brushless motors are quickly finding a place in a modern world that puts priority on using compact, reliable, and efficient technology.

Drones have been particularly well-suited to the adoption of brushless motors. With the increased power that brushless motors are capable of, drone propellers can generate enough lift even for bigger drones and heavy payloads. The compact design of brushless drones has made them suitable for ultra-portable applications, and their enhanced efficiency has greatly improved drone flight times.

With the reliability and improved efficiency of brushless motors, we don’t expect the drone industry to go back to using brushed motors. Even some of the toy drones being sold today have resorted to using brushless motors. The new battleground for drone manufacturers and designers has been how to design better brushless motors and ESCs in a bid to improve all aspect of flight performance.