Beginner’s Guide to Computer Aided Design (CAD)

Technical drawing and design used to be considered a complex skill that only a select few could master like surgery or rocket science. Nevertheless, through Computer Aided Design software, design tasks have become much easier. Computer-Aided Design, (CAD), is the use of computer programs to create, modify, analyze, or optimize precision drawings and is often referred to as Computer Aided Design and Drafting, (CADD). By using CAD, people have been able to save time, energy, and money, consequently increasing the productivity and efficiency of the entire design process.

CAD programs are used to make technical drawings with dimensions and details that are representative of real-world objects such as buildings, cars, airplanes, tools, machines, and ships. These designs are used in various industries such as aerospace, automotive, fashion, film, entertainment, construction, planning, and civil works.

This guide will show you the ropes and help you get started in the world of Computer Aided Design. You will be able to understand what CAD is, its benefits, and how you can learn to use it. You will also get a glimpse of the best CAD software available in the market.

The History of CAD

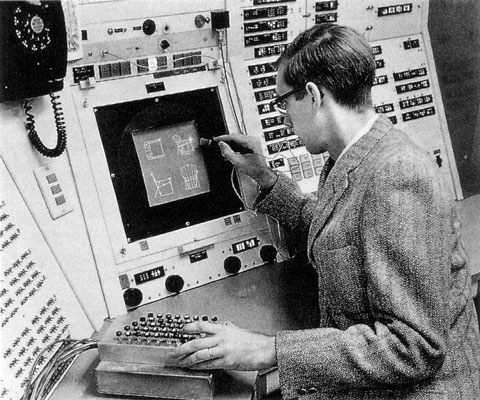

The development of CAD programs began as early as 1949 with applications that were used to analyze and optimize power systems, as well as design circuits using basic geometrical shapes. However, it was the invention of a program called Sketchpad by Ivan Sutherland in the sixties that really set the ball rolling for modern CAD technology. He developed the program as part of his doctoral thesis at Massachusetts Institute of Technology, (MIT), to demonstrate the fundamentals of technical drawing with a computer.

Between the sixties and seventies, the use of CAD was limited to large companies and institutions such as MIT, General Motors, Lockheed, and IBM mainly because computers were expensive and very few people had access to them. However, as computers became smaller and more affordable, people began using them in their homes, offices, and universities leading to a boom in the number of CAD users all over the world.

How CAD works

CAD software was designed to simplify the technical design process and save you the hassle of drawing with paper and pencils. In order to maximize your CAD experience, you need to have a good understanding of computers and technical drawing. The computer program can only do what you direct it to, so the first thing you need is to have a design idea in mind. Once you know what you want to draw, then you can convey the image to the machine.

It is easier to use CAD if you can make working sketches of your idea on paper before making detailed illustrations on the computer. Sketches save a lot of time when working with CAD because they help streamline your focus in accomplishing the task.

Most CAD programs have a small rectangular box or window at the bottom of the screen where you can type instructions or commands according to what you want to draw. This box is known as the Command Window. The programs have several commands and algorithms that result in different combinations of lines, shapes, and curves once typed into the command box.

Command Input Devices

A Command Input device, as the name suggests, is equipment that is used by the designer to feed instructions into the CAD software. The best way to feed commands into the CAD software is to use your regular mouse and keyboard because they are standard equipment that you would normally purchase with your computer. As you work more with Computer-Aided Design, you may develop preferences and working styles that require you to invest in more advanced input equipment such as light pens which use light sensors to choose items on the screen, and touch pads which can allow you to draw freely without the aid of a mouse.

Many CAD professionals invest in special CAD keyboards or mice. The mice are designed to suit the specific needs of a CAD expert. They often have scroll balls to help the user move up and down the screen easily, and some have ergonomic designs to reduce the strain or fatigue caused from using the mouse for long hours. The specialized keyboards have additional keys, shortcuts and sometimes, a non-conventional shape to make the CAD experience more comfortable for the user.

Bluetooth CAD Mouse

CAD users who work a lot on the move are big fans of Bluetooth mice because they are wireless, compact, and easy to travel with. They are preferred over USB wireless mice because they do not need a USB dongle which is normally inserted into the computer for connectivity. They instead use a Bluetooth signal. USB dongles often get lost when traveling.

The main limitation is that they can only work with a Bluetooth enabled computer. If your computer is not Bluetooth enabled, you can either attach a Bluetooth receiver to it or opt for a USB wireless mouse. Another challenge faced by wireless devices is their power source. Some of these mice are rechargeable, while others need you to buy a separate battery. Battery life also varies from one mouse to the other.

| Make and Model | Picture | Battery life | Buttons | Special feature |

|---|---|---|---|---|

| Vic Tsing MM057 |  | 15 Months (AA Batteries) | 6 Buttons | 5 DPI Levels (800 – 2400) |

| Logitech M535 |  | 10 Months (AA Batteries) | 4 buttons | Laser-Grade Optical Sensor |

| Logitech MX Anywhere 2S |  | 70 Days (Rechargeable) | 6 + buttons | Can be used on 3 computers simultaneously |

Vertical Mouse

Vertical Mice are ergonomically designed to mimic the neutral “handshake” position. This concept is aimed at reducing stress and fatigue on the arm and wrist that occurs when you use an ordinary mouse for a long time. The vertical mouse has a wide range of functions due to the inclusion of additional programmable buttons, which can be reached by the user’s fingers, unlike the conventional mouse that only supports the use of two fingers.

| Make and Model | Picture | Sensitivity | Special feature |

|---|---|---|---|

| Jelly Comb MV014 |  | Adjustable DPI 800/1200/1600 | Scientific Ergonomic design |

| Delux M618 Plus |  | Adjustable DPI 800/1200/1600/ 2400/4000 | Ergonomic Design promotes user’s comfort |

| J-Tech Digital V628 |  | Adjustable DPI 600/1000/1600 | Can be used on 3 computers simultaneously |

Graphics Tablet

Graphics tablets are flat touch-sensitive panels that you connect to your computer via a USB port. People really like the wireless versions because they give you the freedom to move around. The tablets are fashioned to let the user make drawings freely without the limitations of a mouse.

In CAD programs, you can make free curves and abstract lines that would require several commands to achieve. Although graphics tablets are best suited for fine arts, painting, and photo editing programs, some architects and aerodynamics designers like to use them to make new unconventional curves and streamline drawings in their projects. Most of these tablets are equipped with customizable buttons for the user to assign functions, and a rechargeable pen for drawing.

Graphics tablets can be rated according to pressure sensitivity levels. The pressure sensitivity simply indicates how much you can vary the thickness or opacity of a line by the amount of pressure you put on it. It is designed to imitate the effect of using a paintbrush or soft pencil where the more pressure you use, the thicker the lines.

| Make and Model | Picture | Size | Number of buttons | Special feature |

|---|---|---|---|---|

| Huion H610PRO |  | 10 by 6.25 Inches | 8 Customizable buttons & 16 hotkeys | 2048 pressure Sensitivity levels |

| XP-PEN Star06C |  | 10 by 6 inches | 6 Shortcut keys and one dial | 8192 Pressure sensitivity levels |

| UGEE M708 |  | 10 by 6 Inches | 8 Customizable hotkeys | 8192 Pressure sensitivity Levels |

Types of CAD Software

Your choice of CAD program will depend on your budget, what you want to use it for, and your personal preferences. For example, architects and electrical engineers may end up using different CAD software simply because of the kind of drawings they want to make.

An architect may need a program that can produce a three dimensional model of a house including its interior finishes, color codes, and furniture layout to sell to a client, while an electrical engineer may simply need a program that can make a flat, black and white drawing of the electrical circuit to guide his electricians. All in all, at the fundamental level, CAD software can either be two dimensional (2D CAD) or three dimensional (3D CAD).

2D CAD

Two dimensional or 2D CAD systems were developed in the seventies and basically consisted of drawings that existed on one flat plane representing only the length and width of an object. These were made using a combination of straight or curvy lines as well as basic geometric shapes such as circles, triangles, and rectangles among others. AutoCAD and CADkey are among the most common 2D CAD programs in use.

3D CAD

Improved computational power and algorithms in the eighties made it possible to incorporate a third dimension into the basic 2D CAD programs and birthed three dimensional or 3D CAD. The 3D CAD systems include the dimension of depth or height in technical drawings enabling the designers to create life-like models of their projects and spin them around to display different angles and views. This helps to visualize a new concept, especially when communicating it to people who may not have technical backgrounds such as marketing teams, clients, and local authorities when seeking permits or support on a project.

3D CAD systems initially only modeled arcs and lines and were referred to as 3D Wire-frame Models. They presented a skeletal representation of the finished product and displayed all internal components of the system.

After wire-frame models, software developers came up with 3D Surface Models. These programs use algorithms to model the outer surface of the designed objects. Their ability to form smooth curves and shapes made them ideal for making the first 3 D models of airplanes, cars, ships, and other objects that had streamlined features.

The most popular 3D CAD programs are referred to as Solid Modeling Software because they have the capability to model every part of the product representing both internal and external components as they would appear in reality. The designers are able to feed details such as the dimensions and density of the materials chosen in order to determine the overall weight of the structure. Some of the best solid modeling software in the market includes SolidWorks and Unigraphics NX.

The Benefits of CAD

CAD software is used in a wide range of technology firms because it saves a lot of time and resources. Before the development and commercialization of CAD, draftsmen were only able to express their work physically on paper. Drawing by hand was a time consuming and physically exhausting exercise. It required close attention to detail and had very little room for error. CAD programs enable the draftsmen to make accurate drawings in a short time with fewer mistakes. Also, modifications to the design can be made quickly and easily. We have highlighted a few benefits of using CAD here below.

Easy File Sharing

Globalization has made it possible for people from different parts of the world to bring their minds together to accomplish mutually beneficial projects. Sharing of concepts and ideas has never been more commonplace as it is today. Multinational companies have employees from different countries and time zones carrying out joint tasks and contributing to the development of collaborative projects.

Before people began using CAD, several man-hours would be spent in meetings, making drawings as well as copies and a lot of time was lost waiting for mail correspondence between vested parties in order to accomplish a single project. All drawings needed to be absolutely accurate as any adjustments would cost too much time and money to incorporate.

CAD has simplified the digitization of technical drawings allowing designers to work together without ever having to meet physically thus saving a lot of travel expenses and other challenges. Active files can be shared and worked on by people with different professions and skill sets at various stages of a project.

For example, an architect can develop the basic framework of a new skyscraper building and send it to a structural engineer to evaluate the structural integrity and determine the best materials to use. After feedback, a sanitation expert can have their take on the water supply and drainage systems. An electrical engineer can then add in the electrical system design and finally, an interior designer can furnish the rooms and select the color themes before presenting a complete concept to the client. All of these specialists are now able to offer their services independently without leaving their homes or offices.

Multiple Layered Drawings

CAD software allows designers and technicians to work on different layers or planes before bringing them together to form a complete design. Layers allow you to isolate parts of your drawing and work on it without the interference or obstruction of other parts of the structure.

Layers are very useful for mechanical drawings that have several interconnecting parts and overlapping components. For example, when designing airplanes, the designer needs to make separate drawings for the outer body of the aircraft (airframe), the fuel system, the hydraulic system, the electrical system, and many other components that need to come together as parts of one finished product. Since all these systems can get mixed up on a single two-dimensional paper, layers come into action.

Manual design methods require the designers to make a number of drawings of the same scale on transparent paper and then place them one on top of the other in order to represent an entire project. CAD programs have layers that make this possible at the click of a mouse. They allow you to use different colors and names for the layers and give you the freedom to adjust any part of any layer without redoing the whole project.

High Drawing Accuracy

CAD systems have preset algorithms that have been programmed to increase the accuracy of drawings. They make it possible to identify the starting point, midpoint, and end point of any straight line in the model automatically. This is useful for symmetrical and interconnected illustrations. There are several ways to make precise drawings in CAD systems. For example, you can use a computer keyboard to type the predetermined length of lines and the exact angles of polygons in order to minimize errors.

Reliable Documentation of the Design Process

With CAD systems, you will be able to keep records of your drawings throughout the entire design process. They help you to document and keep records of your work progress in a neat and presentable format. These records can come in handy when you try to explain your work process to trainees, clients, or superiors.

The systematic documentation function built-into the CAD software is also useful when defending patent cases. The program will be able to show the dates and times that a project was worked on as well as the specific computer that was used. This is could be instrumental information whenever you need to defend the authenticity of your work.

Structural integrity

Advanced CAD systems such as solid modeling programs are able to simulate stress tests on 3D models. This function is most beneficial for products that have moving parts or that are designed to bear certain loads. Solid modeling software such as SolidWorks will allow you to input the product material, its density, and performance features and limitations. Some programs have preloaded features of materials such as cast iron, steel, and titanium so that you only need to select them from a given list.

Once you have designed the product and assigned the material details, you can initiate a stress analysis test on the model to see at what point the system fails. It is also useful when designing molds and you need to know whether the material in the mold will flow correctly.

Manufacturers save a lot of money and time by making use of features like this one. It enables them to identify flaws in the design of their products before they spend valuable resources to make a prototype. The stress analysis test and other similar applications help the user to modify the design freely until they find a configuration that fulfills the desired performance requirements.

These CAD options also help manufacturers simulate the use of different materials to make the same product enabling them to select the best material based on cost and performance without spending a cent.

Getting Started With CAD

Now that you have a pretty good idea what CAD is and how it works, it is time to figure out how to start your own CAD story. There are several things to look into when you are getting started with CAD software but we will only list a few of them here to get you off on the right track.

Software Choice

Your choice of CAD software is based on a wide range of factors such as your purpose for using CAD, budget, and personal preference among others. However, a lot of people simply start out with whatever software is available to them.

AutoCAD, developed by Autodesk, is the first CAD software that most people use. AutoCAD is the preferred CAD software for universities and students because it is easy to teach and it offers several training options including membership of the Autodesk Design Academy. The Autodesk Design Academy provides free educational resources, self-paced online courses, tutorials, and competitions to help you learn the program. The most recent version of this software is AutoCAD 2019 and is available through subscription on the Autodesk website. It is the highest ranking CAD software in 2018.

If you are looking for a balance between great functionality and affordability, TurboCAD Deluxe is the product for you. It is reasonably priced at under $200 and comes highly recommended for user-friendliness. TurboCAD deluxe has additional tools such as House Wizard TM that helps you learn how to use the program quickly.

Another program to keep an eye out for is Solid Works. This program is one of the easiest to use on the market and it has built-in tutorials to help you understand its quirks and shortcuts. Solid Works incorporates stress analysis functions that can help to check the integrity of your design. Solid Works is intermediate software because it is easy to use but does not have very high rendering capabilities. It has a user-friendly interface that makes it a good learning tool and a ready option for teaching solid modeling in schools. Solid Works is a product of Dassault Systems who are famous for producing one of the most expensive CAD software, CATIA. CATIA is a product of choice for seasoned engineers. Despite its high price, it offers some of the most powerful CAD tools suitable for designing complex engineering systems for use in the hydropower, aerospace, and thermal power industries.

Computer System Compatibility

Your choice of software must be compatible with the equipment available to you. It is important to find out if the processing speed of your computer or laptop is good enough to operate the software you want to install. You also need to know the amount of RAM (the memory available to run programs), disk space, and the operating system recommended for each CAD software. The collection of this information for a particular CAD program makes up the system requirements. The lowest configuration of components acceptable to make the program work is defined as its minimum system requirements.

As CAD technology improves, you find that newer software has higher system requirements than an older version of the same software. This is the case with Autodesk who release a new version of AutoCAD every year. For example, AutoCAD software from 2016 and above needs 4 GB RAM for 64 bit systems while the previous versions only needed 2 GB RAM.

If you are just getting started with CAD, or if you only have access to basic computers with low specs, we advise you to either go for 2D CAD programs or older versions of CAD software. Older versions of software are often cheaper and contain lower system requirements. 2D CAD software often has low system requirements when compared to 3D CAD systems. Further, as a beginner, it may be good to focus on and master the 2D system before moving on to the three-dimensional programs.

Training

As a CAD beginner, it is important to invest in training opportunities. It does not matter how good your software is if you don’t know how to use it. A large number of CAD users have not mastered the potential of the software they have and as a result, they waste a lot of time going round in circles.

Most credible CAD software producers also offer training tutorials and online courses to go with their products. Nevertheless, the wider CAD community has made support services available and easily accessible through forums, YouTube channels, and dedicated websites. Below are a list of three free and three paid CAD training programs that can be found online.

Paid learning programs usually have more resources and often include support to answer your questions and manage your account. You can find a private tutor in case you need special attention in your study of CAD. Tutors cost much more per hour than online courses or university classes, but you can learn a lot in a very short time. A good tutor can improve your performance quickly because he can identify your unique challenges and help you overcome them.

Conclusion

CAD software has revolutionized the world of technical drawing and drafting. The impact these of programs are endless because they are used in a wide range of industries including aeronautical, automotive, fashion, and the film industry.

The most important thing you can do if you are interested in CAD is to start collecting information. Reading tutorials and books or attending classes can really help you make informed decisions when you want to buy the program for your own use.

This beginner’s guide basically gives you a glimpse into the world of Computer-Aided Design. The best way to get started is to take action. Borrowing from ancient Chinese wisdom, ‘A journey of a thousand miles begins with one step’.

Contents

- The History of CAD

- How CAD works

- Command Input Devices

- Bluetooth CAD Mouse

- Graphics Tablet

- Types of CAD Software

- 2D CAD

- 3D CAD

- The Benefits of CAD

- Easy File Sharing

- Multiple Layered Drawings

- High Drawing Accuracy

- Reliable Documentation of the Design Process

- Structural integrity

- Getting Started With CAD

- Software Choice

- Computer System Compatibility

- Training

- Conclusion

https://freeuptodatesoftware.com/cms-intellicad-premium-free-download/uilt With intellicad 10.1 Engine.