Cardboard Spool Vs. MasterSpool – Which is More Sustainable?

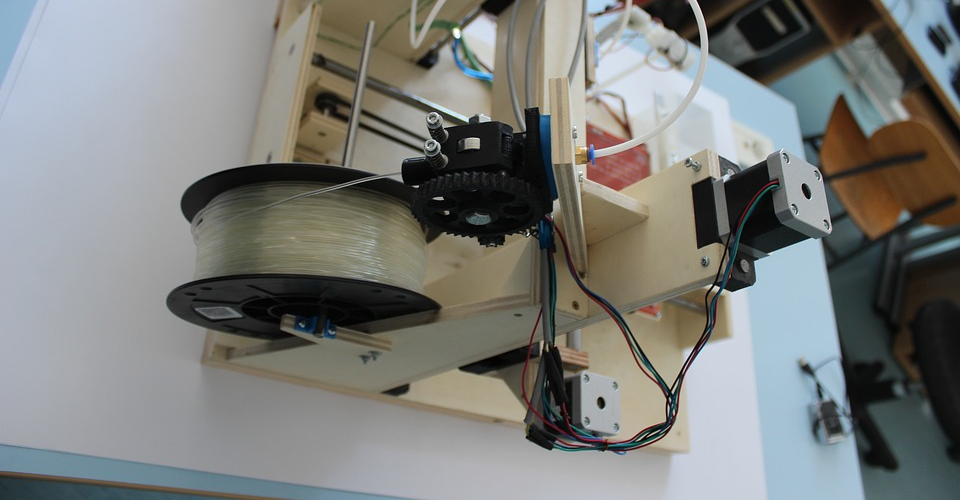

FDM technology has played a huge role in making 3D printing more accessible than ever. Filament-based 3D printers are cheap, easy to learn, and make use of similarly inexpensive plastic filament as raw material.

One problem that is yet to be resolved is the huge amount of waste generated by 3D printing. While the use of plastic-based filaments is all but unavoidable, there is even more waste coming from the plastic spools that the filaments come in. There are two proposed solutions to this problem – spools made of cardboard or “MasterSpools.” Which solution is more practical and sustainable over the long run?

The problem of plastic spools

Anyone who has been 3D printing with filaments can probably relate to the problem of plastic spools. These empty spools can accumulate very quickly, hogging up precious space in our workshops. While there are several ways to repurpose a filament spool, you’re only going to need so many DIY desktop organizers before you find yourself with an excess of empty spools again.

Ideally, the best solution to this problem is for these empty spools to be reused. However, this does not seem possible for now in the absence of filament manufacturers that will support such an initiative. We know of only two brands – Filamentive and Azure Film – that provide incentives for customers who return empty spools.

This problem stems from the fact that plastic spools and other plastic products are so cheap to manufacture. It is more profitable for these brands to keep on producing new plastic spools than to spend on the shipping of used spools for reusing.

The burden now falls to the recycling facilities, not all of which are equipped to handle the shape and material of empty filament spools. Also worth considering is the fact that not all places even have recycling facilities – this is very important in the context of the global reach of filament-based 3D printing.

Buying filaments in cardboard spools

A seemingly obvious solution to this problem is to stop using plastic for filament spools. This is the approach taken by brands such as ProtoPasta and SainSmart. Instead of plastic, the spools from these brands are made of corrugated cardboard.

The idea behind using cardboard is fairly obvious – it comes from more sustainable sources and can be more easily recycled. For their part, ProtoPasta recognizes some buyers may feel that filament in a cardboard spool is less premium. However, they have stuck to their guns for the last few years and seem committed to waste reduction, even though their choices can be unpopular.

If this idea was so good, then why aren’t more filament manufacturers doing it? There are a couple of reasons for this. The use of cardboard over plastic spools does not necessarily translate to cost savings on the part of the manufacturer. In some cases (and with enough volume), plastic spools can even turn out to be cheaper than cardboard ones. For this reason, filament from brands like ProtoPasta are still significantly more expensive than those from Hatchbox and eSun – only two of the many filament brands that use plastic spools.

Durability is another area where cardboard spools suffer. Plastic spools are very tough, have good flexibility, and are virtually weatherproof. It does not help the sustainability movement that there have been cases of cardboard spools getting damaged or deformed either during shipping or when in storage. There’s pretty much no going around the fact that plastic is a lot stronger than cardboard.

What is a MasterSpool?

The MasterSpool is a 3D printable spool design that can be opened apart at the middle and transferred from one filament to another. The idea behind the concept was to make truly reusable spools that do not need to be returned to the filament manufacturer.

If this idea takes off, it will mean that filament manufacturers can start shipping their products without a spool. The alternative packaging for the filaments meant to be used with MasterSpools uses simple cable ties and shrink-wrapped plastic. Although these are still non-sustainable, they still use much less plastic than the 250-gram spools used today.

Since the concept was first developed in 2016, the design of the MasterSpool has been revised and improved multiple times. It remains free for everyone to use and can be downloaded from Thingiverse.

To support the cause, some brands such as FilaCube and 3D Solutech have started to offer MasterSpool-compatible options for their filaments. There are also filaments (such as this one from SUNLU) that ship in a reusable MasterSpool.

The challenges of MasterSpool adoption

The biggest barrier to making filaments MasterSpool-ready lies in the manufacturing process. Under normal circumstances, the filament is extruded, cooled, and wound on the same spools in which they ship. The MasterSpool concept overhauls this process significantly. The filaments will have to be spooled in an intermediate spool, removed, and packaged differently. Making this change in the process can be a huge investment for the manufacturer.

Making this investment would have been fine if most 3D printing users favor the shift to the MasterSpool. This does not seem to be the case. Many buyers still prefer the convenience of single-use plastic spools. After all, a filament that has been pre-wound at a spool doesn’t take a lot of work on the part of the buyer and will behave more predictably.

Relying on customers to transfer a filament from its packaging to the MasterSpool will inevitably result in failures. When this happens, the customer will have no choice but to wi

There’s also the difficulty of having to print a new MasterSpool for every new filament that a customer buys. This is fine if you’re keeping five to ten spools at a time on reserve, but 3D printing businesses that can have an inventory of a hundred filament spools would have a really hard time keeping up.

Despite being a simple concept, almost two-thirds of respondents in a survey said that they prefer using filaments with cardboard spools than having to print and use a MasterSpool. The appeal of “plug and play” spools very likely plays a huge role in this consumer behavior.

Which option is more sustainable?

While both options are more sustainable alternatives in the context of their environmental impact, we still need to determine which one is more “sustainable” in terms of market adoption. After all, a strategy will only be effective if the consumers and manufacturers will support the movement.

While the MasterSpool Initiative is a brilliant concept, it is still struggling to find its footing after all these years. It all comes down to the lack of convenience – using a MasterSpool meant transferring a new filament to the spool every time. If something goes wrong mid-way, then you end up with an even bigger problem.

Even the filament manufacturers aren’t all that crazy about overhauling their filament winding equipment to accommodate these “spool-less” filaments. This extra step introduces more unpredictability to the process, which means that filament quality may suffer.

So far, it seems that more people are warming up to the idea of cardboard spools. While it’s still not universally accepted, the idea of filament in cardboard spools seems more palatable to 3D printing enthusiasts.

Even though cardboard spools seem to be the more sustainable option right now, they still need a lot of work. There are still a lot of cardboard spools in the market right now that aren’t readily recyclable because of paints and wax coatings. If filament manufacturers were sincere about their efforts to be more environmentally sustainable, they would do away with “greenwashing” practices and make cardboard spools that are truly recyclable or biodegradable.

This doesn’t mean that we can do away with the MasterSpool concept. This movement has had significant support through the years, both from users and filament manufacturers. There has also been a concerted effort to improve the design of the MasterSpool. With improved designs and better industry support, we may yet see the MasterSpool movement gain a larger following.

While it’s true that transferring unspooled filament to a MasterSpool is less convenient for the buyer, we must also accept a certain threshold of inconvenience in the name of sustainability. Change, especially when it’s for a good cause, rarely comes without effort. “Spool-less” filaments still generate less solid waste and will be better for the environment in the long run.

Final thoughts

The environmental impact of 3D printing has always been an issue that has hounded this industry. 3D printing product prototypes and commercial products is one thing, but can a person doing this for fun really justify all the solid waste generated by the activity? There is no question that the 3D printing industry needs to do better.

One area that can be more easily addressed is the use of single-use plastic spools. While these are convenient, they often just find their way into landfills or recycling facilities. The MasterSpool concept and cardboard spools provide more sustainable options but are yet to make a dent on the market that prefers the convenience of single-use plastic spools.