Cartesian, Delta, and Polar 3D Printers: What are They and What’s the Difference?

The increasing popularity and utilization of 3D printing technology have resulted in the evolution of 3D printers over the years. Heated printing beds, Bowden extruders, print bed enclosures – these are just some of the features and accessories that the 3D printing industry has come up with to create better quality 3D prints.

One of the most drastic and apparent changes that have come to 3D printers comes with the development of Delta and Polar 3D printers. These printer types massively deviated from the design and workflow of the traditional Cartesian printer. What’s the difference between the three types? Is one better than the other?

Coordinate systems: a short introduction

A coordinate system is used to define the location of any point in 2D or 3D space. This is typically done by a series of numbers, the order of which is usually significant. For a common example, the system of longitude and latitude defines the location of any point in the Earth using a pre-defined grid. Longitude and latitude readings can be further enhanced by defining the elevation of the point, determined as a function of atmospheric pressure measurements.

Coordinate systems play a big role in how 3D printers work. Each point in the 3D model is defined by a set of coordinates in 3D space, which the data translates into particular points in the real-world space of the build platform. Therefore, how the coordinate system defines the points of the model dictate the direction and distance of movement of the print head or the build platform.

The names of the different 3D printers – Cartesian, Delta, and Polar – provide an insight as to how they differ in terms of coordinate systems. Each coordinate system will be expounded upon on the individual sections below.

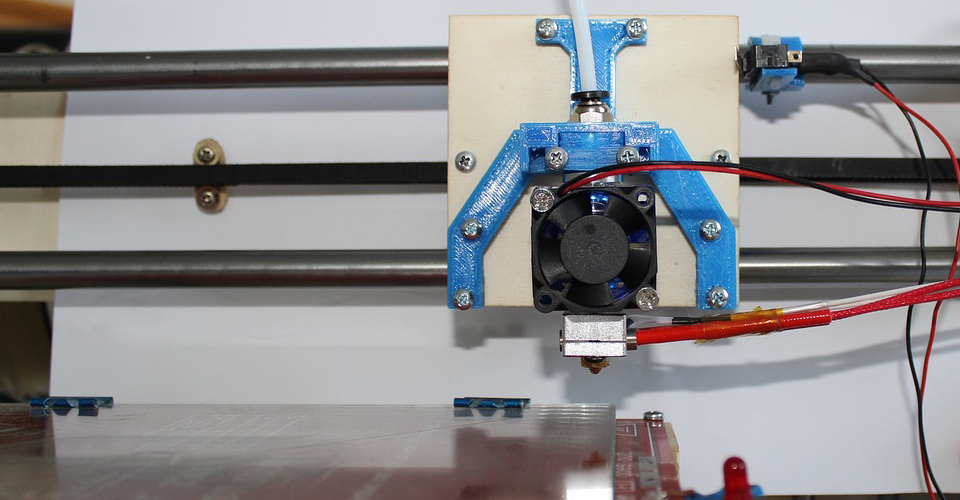

Cartesian 3D printers

By far, Cartesian 3D printers comprise the bulk of desktop and commercial FDM 3D printers used today. It is based on the Cartesian coordinate system, which is one of the most fundamental coordinate systems used in a wide range of industrial and academic applications. The cartesian coordinate system uses three numbers to define the location of a point in space – x, y, and z. The sequence of these numbers is important, as they are an industry standard.

Simply put, the x and y numbers define the lateral and longitudinal position of a point, while the z number defines its elevation. In a standard Cartesian 3D printer, each layer is printed using the x and y coordinates of every single point before the print head moves up by one layer height. It then proceeds to print the next layer that corresponds to the z coordinate of the print head’s current height.

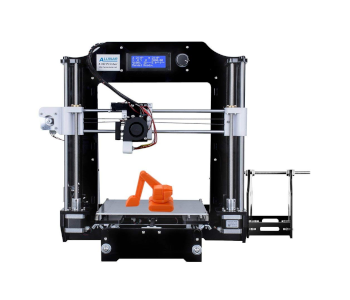

The biggest advantage of using a Cartesian 3D Printer is the fact that it’s the most common 3D printer out there. It’s easy to find a community of experts that can give you advice on how to tweak or troubleshoot your Cartesian 3D Printer. Finding replacement parts is also easy when you have a very common 3D printer model. If you’re looking for an affordable desktop 3D printer, chances are you’ll end up with one of a Cartesian variety.

Most of the efforts of the 3D printing industry have gone into making innovative and more user-friendly Cartesian 3D printers. Nowadays, Cartesian 3D printers can be purchased in ready-to-use, fully assembled kits. With minimal setup, you can have a be printing with your Cartesian 3D printer in a matter of minutes.

Cartesian 3D printers can have different motion schemes. Some models may have fully stationary build platforms, while others have platforms that can move in one or two directions. In any case, a Cartesian 3D printer will have a minimum of three stepper motors – one for each direction in the Cartesian plane.

Since the print head of a Cartesian 3D printer is typically suspended from above, they have much wider build platforms. This is perfect for printing models with wide bases. However, the height of a build that you can create with a Cartesian 3D printer is limited by the maximum height of the print head.

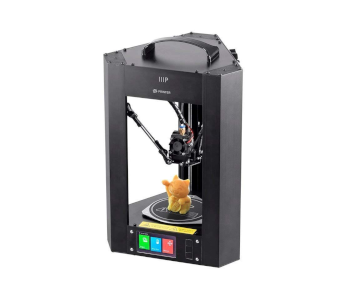

Delta 3D Printers

Delta 3D Printers are easy to identify by their appearance alone. In a Delta 3D Printer, the extruder is suspended not from above, but by three arms position in a triangular configuration. The three arms push and pull on the extruder to position it according to the model being printed.

Despite the unusual configuration of Delta 3D Printers, it still builds prints according to the Cartesian coordinate system. Instead of positioning the print head according to x, y, and z positions, each of the three arms changes its angle to position the print head on the build platform according to the model. Hitting the precise location is done by a series of trigonometric functions that consider the angle of all positioning arms. Due to their triangular build, Delta 3D Printers typically have a circular build platform which makes them more appropriate for circular prints.

The biggest advantage of Delta 3D Printers is the fact that they were built for speed. By using three arms to control the position of the print head, a Delta 3D Printer manages to move the weight of the stepper motors away from the extruder. Delta 3D Printers also typically use a Bowden extruder to further lighten the print head. This allows the print head of Delta 3D Printers to move extremely fast. If you need a print to be done quickly, then using a Delta 3D Printer is still your best bet.

Unfortunately, Delta 3D Printers are not immune from problems of inertia and momentum carryover that limit the printing speed in Cartesian 3D Printers. Although they are designed for speed, Delta 3D Printers have earned a reputation for having low precision, resulting in prints with less detail and a rougher finish.

Delta 3D Printers are also a little more complex compared to their Cartesian counterparts. Most Delta 3D Printers come in kits that need to be assembled, which is fine for more experienced users but may be off-putting for beginners. The use of Bowden extruders is quite limiting in terms of the types of filament that you can use with Delta 3D Printers. As many 3D printing professionals know, Bowden extruders are problematic when used with flexible filaments due to the increased chances of the filament deforming along the longer filament path.

Delta 3D Printers are thin and long. They typically have a small, circular base that limits their use to models with small bases. However, they excel in building tall models. If you’re planning on building a model of a Greek column, then a Delta 3D Printer may be just the thing for you.

Polar 3D Printers

Of the three types of printers discussed here, the Polar 3D Printer is certainly the rarest. This is still considered an emerging design, but more and more 3D printing professionals are starting to recognize how advantageous it could be. Instead of using a Cartesian coordinate system, Polar 3D Printers use a polar coordinate system. In this system, points are defined using only two numbers: an angle in 3D space, and a separation distance (or radius) from a pre-defined center.

Watching a Polar 3D Printer in action is mesmerizing. The moving mechanisms are very different from what we are used to seeing in Cartesian 3D Printers. Instead of a stationary build platform, the print bed of a Polar 3D Printer can rotate, move left and right, or move back and forth. This makes it possible to have a print bed that is almost stationary – it only moves up and down when switching to another layer. This very ingenious design allows Polar 3D Printers to create great build volume using a much smaller space.

Polar 3D Printers are also very power-efficient since they can function with just two stepper motors: one to rotate and move the build platform, and another to control the elevation of the print head.

Obviously, the biggest disadvantage of using a Polar 3D Printer is that it’s not yet so common. There’s limited support or parts available for these types of printers. Their rarity also makes them expensive – a Polar 3D Printer will cost more than twice a comparable Cartesian 3D Printer. However, the wider acceptance of Polar 3D Printers seems to be on the horizon. Hopefully, this brings about better accessibility for this type of technology.

Which one is better?

Each type of 3D printer has its own merits, so it’s unfair to categorically state that one is better than another. Cartesian 3D Printers enjoy the advantage of being so common and popular that they have now become so much cheaper and more user-friendly. They also function more intuitively – our brains are wired to easily comprehend movement and positioning in the Cartesian coordinate system. If this your first foray in the world of 3D printing, then we strongly recommend starting with a Cartesian 3D Printer.

Delta 3D Printers should be reserved for more specialized applications. This type of 3D printer can build fast and build high – two characteristics that introduce a host of problems on their own. It will require a deep understanding of how layer adhesion works before you can get good results with a Delta 3D Printer. If you think you have a good handle of the techniques and adjustments needed to get good results in a variety of 3D printing conditions, then you may consider getting a Delta 3D Printer.

Polar 3D Printers are still a bit too specialized and expensive for casual 3D printing. Admittedly, there are a lot of advantages to using Polar 3D Printers, such as a smaller footprint and more efficient power consumption. They also print fast and excel in creating builds with a lot of circular elements. However, the technology is firmly still in the development phase, and there likely aren’t many experts in this field that you can rely on for support. Our suggestion is to let the technology mature for a while so that you can get it in a more affordable and user-friendly form.

The future: 3D printers with robotic arms

Outside of these three types, a few inventive and enterprising people have come up with even more exotic ways of 3D printing. One example is the Selective Compliance Assembly Robotic Arm (SCARA) which was developed by Nicholas Seward. As its name implies, this 3D printer uses a print head mounted on an articulated arm, much like a robotic component of a car assembly line. The articulated arm affords a much a higher degree of mobility which, in theory, should be able to produce more complex builds.

Naturally, this type of 3D printing technology is not yet available on a commercial scale. Right now, it’s just a glimpse of what the future of 3D printing could look like. As long-time 3D printing enthusiasts, we are looking forward to this level of 3D printing technology to take off.

Final thoughts

It’s pretty amazing to see how far 3D printing technology has come. From industrial-sized 3D printers, we are now in the era where desktop-scale builders can come up with their own inventive builds using very user-friendly and affordable 3D printers.

The branching out of FDM printers into Cartesian, Delta, and Polar varieties may just be the start of how consumer-scale 3D printing technology could diversify. With better technology, we may reach a point where we no longer have to compromise between printing speed and build quality.