Is CNC Machining A Good Option for Prototyping?

The old machining methods, such as milling or turning, have been around for several decades. With CNC technology, these old machining methods have become more precise and reliable than even and no longer depend on the level of skill of the human operator. Although CNC machining has always been one of the go-to options for prototyping, its position has now been challenged by the even more modern technology of 3D printing.

In 2020, is there still any good reason to have prototyping jobs done via CNC machining? What advantages does it have over 3D printing?

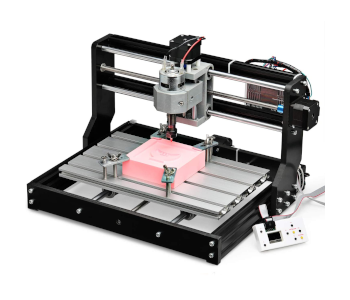

What is CNC machining?

Machining, in a general sense, refers to the use of various cutting tools to wear down a solid block of material into the desired shape. There is evidence of machining techniques being practiced way back in 700 BC, crude as these techniques may be. Around the time of the Industrial Revolution, steam-powered machining tools were developed, thus reducing the need for manual work. Various machining tools like mills, lathes, grinders, and routers were already around by then.

Around the 1950s, the development of computers and a growing market demand provided the impetus for the development of CNC machines. CNC stands for “Computer Numeric Control,” a method for the machining tools to be programmed using a computer and operate completely autonomously.

For a CNC machine to execute a design, the process needs to start with a 3D model typically designed in a CAD platform. This visual model is then converted into a series of G-Code commands. G-Code is a basic programming code recognized by CNC machines and is pretty much just a straightforward list of commands. For instance, the G-Code will command the tool to move to a specific location based on x and y coordinates and run for a specified length of time.

The use of CNC as a control mechanism has made machining a faster, more reliable, more precise, and safer process. Some CNC machines have been known to hit accuracy at a level of 0.001 mm. Being fully automated, CNC machines can attain this level of accuracy for each product they make, making them uniquely suitable for mass-scale production. The use of 3D models also grants manufacturers a higher degree of design freedom, which makes CNC machines suitable for prototyping.

CNC machining is an example of a subtractive manufacturing technique. This means that it cuts down unnecessary material from a solid block to create parts of the desired shape and size. This has advantages and consequences, as we shall see later.

Why consider CNC machining for prototyping?

For most of the history of manufacturing, machining has always been the go-to technique for prototyping. The mills, lathes, and turners are uniquely capable of creating custom-made parts, especially when they aided by a CNC program based on a 3D model. CNC machines work fast, are extremely accurate, and can be made to work with versatile designs.

The rise of 3D printing revolutionized the field of prototyping, effectively giving competition to CNC machining. In contrast to CNC machining, 3D printing is an additive manufacturing method. This means that it manifests 3D designs in the real world by adding one layer of material on top of another. This gives 3D printing a leg up when it comes to design freedom, although it’s not an absolutely perfect technique either.

However, CNC machining has one crucial advantage – strength. Since CNC machines create custom designs from a solid block of material, they retain the mechanical integrity of the original material. In contrast, 3D printing relies on the principle of breaking down the raw materials, either in the form of power of molten filament, and putting them together again. This creates natural weak points and parts that have poor tensile strength.

This means that prototypes made via CNC machining more than just look the part – they can also completely functional. This is rarely possible with 3D printing. CNC machining also creates prototypes that will more closely simulate an actual finished product, as 3D printers aren’t exactly suitable for mass-scale production.

Pros and cons of prototyping using CNC machining

The choice between CNC machining and 3D printing is often a question of compatibility. Each option has its benefits, as well as its limitation. For CNC machining, these are the pros and cons to consider:

PROS:

Suitable for functional or production-grade prototypes

While 3D printing is a quick and inexpensive way to come up with visual prototypes, they lack the mechanical integrity and strength for most functional uses. This is where CNC machining comes in. Prototypes made via CNC machining aren’t merely props or a visual representation of the finished product – they represent how the product will look, feel, and perform after it has been through an actual production line. CNC machined parts also have the advantage of having isotropic properties, which means that they are constant across all dimensions.

Product development can also greatly benefit from creating prototypes via CNC machining, especially if they have gone through the phase of nailing the look of the product. CNC machined parts provide an opportunity to test the prototype for function, strength, ease of assembly, resistance to wear, and longevity.

Extensive range of materials

For all the versatility of 3D printing, it actually has a limited range of materials it can work with. FDM printing is mostly plastic-based, with few exceptions made for composite filaments that may have other solid particles embedded in a thermoplastic matrix. DMLS and SLM techniques can produce metal parts from the sintering or melting of metal powder. However, these techniques are quite rare still suffer from poor mechanical integrity typical of 3D printing.

By its very principle, all a CNC machine needs is a solid block of any material. CNC machines can work with a wide range of both plastics and metals. Even hard metals, like titanium or stainless steel, can be cut down to shape using diamond-tipped drills and cutting tools.

CONS:

Reduced design freedom

Starting with a solid black and cutting it down from the outside limits the complexity of designs that can be recreated via CNC machining. In particular, designs with hollow sections and complex internal geometries may prove to be difficult or outright impossible for CNC machining.

There is another layer to this argument. If a prototype cannot be done via CNC machining, then how can it be recreated at a mass-scale production line? 3D printing may be capable of creating just about any type of geometry, but not many manufacturers use 3D printers as the primary means of production, especially if turnover times are a huge concern.

Thus, prototyping via CNC machining also serves to test the compatibility of a prototype with currently existing manufacturing equipment. This emphasizes a central point – just about all manufacturing lines use some form of CNC technology.

More expensive

Just about all elements of CNC machining are more expensive than 3D printing. From the CNC equipment, instrumentation expertise, the power consumed by the process, and the blocks of solid raw materials, running a CNC operation requires substantial expenses, both in terms of capital and operational costs.

CNC machines are also heavily specialized. A lathe has uses that are unique to a mill, as does a grinder. In some cases, a fully functioning prototype will require the work of several of these equipment. It’s not hard to imagine the costs of acquiring and operating a veritable array of CNC machines.

In contrast, a single 3D printer can be used to come up with a variety of prototypes. Since a 3D printer has fewer limits when it comes to part geometry, its major limitation is related to build volume. However, that can be easily remedied by splitting a 3D model into parts.

Creating prototypes from metals is obviously more expensive than using plastics, but the additive aspect of CNC machining also has a few undesirable consequences. Cutting down the material to create the desired shape means that a substantial portion of the original material becomes waste. Given how valuable these metals are, most manufacturers would opt to recycle the scrap metals for later use. However, recycling is also a process that costs money.

In contrast, an additive manufacturing process like 3D printing generates minimal waste. Unless a design needs support structures, a 3D printing process only consumes as much raw material as the design dictates.

Final thoughts

For as long as new products continue to be developed, prototyping will remain an essential part of any industry. The only question remains is how to best create these prototypes, considering factors such as visual appearance, functionality, mechanical integrity, and design freedom. Two technologies are at the forefront of addressing this dilemma – CNC machining and 3D printing.

CNC machining may be an old technology, but there’s no doubt that it still has a place in the modern industrial setting. The same can be said of prototyping. CNC machined prototypes are much stronger compared to 3D printed ones and more closely resemble how a part will perform after it has been manufactured in an actual production line. 3D printing may be the new kid on the block, but CNC machining will always be here to stay.