CO2 Laser vs. Fiber Laser: How Are They Different?

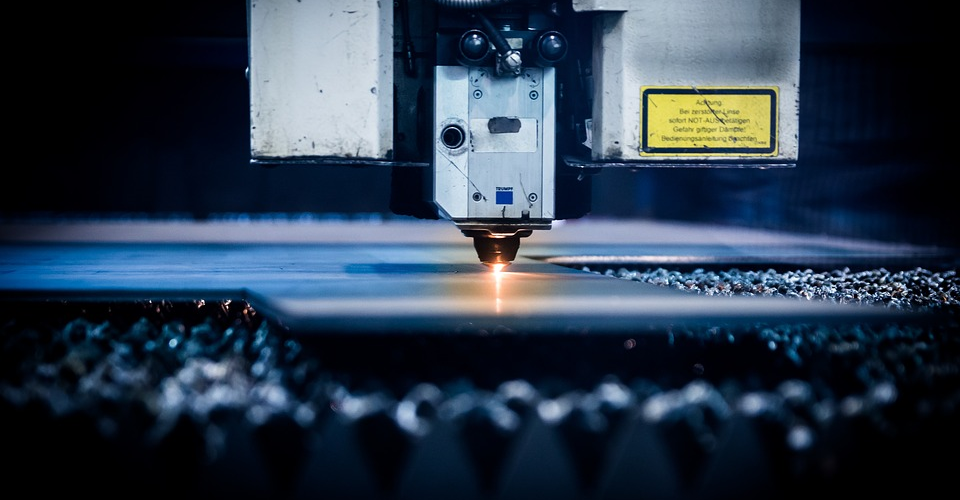

Lasers are still relatively new tools in the manufacturing industries, but many would agree that they have huge potential. They are fast, suitable for a wide range of materials, highly reliable, able to reproduce intricate designs, and are mostly automated. Using a laser for cutting, making, and engraving presents a lot of benefits compared to the more traditional rotary tools.

When making the shift to laser technology, a manufacturer is given another choice – to pick between either a CO2 laser or a fiber laser. As with any worthy dilemma, there are benefits and drawbacks to be considered in either option.

Fiber Laser

How they work

A fiber laser is made of several essential parts, but we are going to focus on just two of them to understand how they work. The first is the laser’s active gain medium, which is an optical fiber doped with rare earth elements. The most commonly used element in fiber lasers is erbium, although there are others that use neodymium, thulium, and ytterbium among others.

What makes rare earth elements so special? The rare earth elements, present as ions in the optical fiber, can absorb light in almost every region of the visible to near-infrared spectrum. In practice, this means that a cheap diode laser pump can emit light at 980 nm, which will then be decayed by an erbium-doped fiber to an equivalent of 1550 nm. This results in greater control of the laser and the emission of a high-power laser beam.

Rare earth elements are very optically stable are relatively insensitive to host materials. Regardless, there are specific host glasses considered to be most suitable for each of the commonly used rare earth elements. For instance, silicate glass is used for ytterbium-doped fibers, while phosphate glass can be an alternative option for erbium-doped fibers. The metastable states of rare earth elements have longer lifetimes and have high quantum efficiency.

For the photons emitted by the laser diode to be constricted within the fiber core, they are entrapped by the second essential part of a fiber laser – the Fiber Bragg Grating. This is simply a cylindrical section of glass with a cladding that has sections of a different refractive index than the rest of the glass material. This allows for selective transmission of the photon particles inside the fiber core, which means that some of the light is transmitted while the rest is reflected back.

The amplification of power via internal reflection is what is referred to as optical gain. Due to the compact nature of a fiber laser, its active region can be equivalent to several kilometers long. This also means that a fiber laser has a very high surface area to volume ratio, meaning that it generates relatively low heat for the amount of power it generates.

The Fiber Bragg Grating not only helps with the control of the emitted laser beam, but the internal reflection of the photons allows for more absorption of pump light by the core. This allows fiber lasers to be ultra-focused and deliver a high power output.

Pros

Delivers a high-powered laser beam

The unique design of a fiber laser allows it to output a high-quality laser beam using a cheap diode light source. Quality, in this regard, relates to both power and precision. The high optical gain of fiber lasers means that they can have power outputs of up to 6 kW. When the laser is ultra-focused, it is powerful enough to easily cut through thick metals. In terms of intensity, a fiber laser can be up to 100 times more powerful than a CO2 laser.

The mechanism of internal reflections within the core of the fiber also allows for a fiber laser beam to be extremely small. Aside from the power magnification of such a design, it also means that fiber lasers are suitable for highly precise cutting and marking needs.

High efficiency

A fiber laser can convert 70% to 80% of the power input, which is a much higher mark than other laser technologies. This has two distinct benefits. In the long term, large-scale manufacturers can save on the power costs of running a fiber laser. The high efficiency also means that less of the input energy turns into “waste” heat, which means that fiber lasers are relatively easy to keep cool despite operating at a high power output.

Resistant to noise and vibrations

The optical gain of a fiber laser is dependent on a medium that is inherently flexible. It does not rely on sensitive optics – instead, all its reflective components are housed inside the fiber. This makes a fiber laser much less sensitive to movement, vibration, or low-amplitude noise. This is quite advantageous in the heavy environments found in most manufacturing industries.

Minimal maintenance needs

Not having to rely on sensitive optics also makes fiber lasers require very low maintenance. With most fiber lasers rated at a minimum of 100,000 operating hours, fiber lasers are essentially “fit and forget” machines. Even when they require maintenance, the costs of maintaining fiber lasers are typically only about half of the other lasers.

Cons

High initial costs

While you may save on power and maintenance costs with a fiber laser in the long run, the machine itself is very expensive. A fiber laser machine will cost at least $40,000, with high-end models even reaching up to the million-dollar range. This makes fiber lasers inaccessible for smaller manufacturers and those who are looking for a laser engraving machine for small-volume orders.

CO2 Laser

How they work

CO2 laser technology is one of the earliest lasers to be developed and is one that is still widely used today. CO2 lasers have fairly simple mechanisms, are relatively efficient, and remain to be the highest-power continuous wave lasers used today.

The active laser medium of a CO2 laser is a discharge tube filled with gases. Despite its name, the gas chamber of a CO2 laser is actually filled with equal parts of carbon dioxide and nitrogen with smaller percentages of helium, hydrogen, and xenon. The proportions of each gas may be altered according to the specific application of the laser.

The input of a CO2 laser is an electric current introduced directly into the gas discharge tube. The impact of electrons results in the addition of energy into the nitrogen molecules in the chamber, causing them to vibrate. Nitrogen cannot lose this energy by photon emission but instead will transfer the vibration energy to the carbon dioxide molecules via perfect resonance.

Carbon dioxide, in its excited state, has the potential to release the excess energy as photons. However, this will only occur once the carbon dioxide gets in contact with the relatively cold atoms of helium.

The energy of the photos released from the change in transition level of electrons in the carbon dioxide is relatively low and does not have enough intensity to cut or engrave most materials. To amplify the strength of the beam of a CO2 laser, a series of internal reflections is generated by an array of mirrors surrounding the discharge tube.

A typical CO2 laser build consists of a gas discharge with a total reflector at one and a partially reflecting mirror at the output. The mirrors used are usually silvered, although gold mirrors can be found in lasers meant for high-powered equipment. The windows and lenses are usually made of zinc selenide, but some more expensive models use diamond windows because of their superior hardness and high thermal conductivity.

There are some ways to customize the parameters of CO2 lasers. The first is to vary the isotopic ratio of the carbon and oxygen atoms in the discharge tube. For instance, heavier isotopes will release light with a longer wavelength. Some CO2 lasers also come with adjustable diffraction gratings. This allows for fine-tuning of the frequency of the emitted laser beam.

Pros

Lower initial cost

CO2 lasers remain the preferred technology for a wide range of industries because they deliver reliable performance at a fraction of the cost of fiber lasers. The price of equipment for CO2 laser cutting or engraving starts at $35,000 but rarely goes beyond $100,000. This makes for faster return of investment, even for small-volume orders.

More suitable for diverse materials

CO2 lasers are much easier to control. Combined with their inherently lower power outputs, this makes CO2 lasers more suitable for a wide range of materials, including non-metallic ones like textiles, wood, and plastics. This versatility is one of the primary reasons for why CO2 lasers have remained very popular, despite being one of the earliest laser technologies. CO2 lasers are used for industrial cutting and marking, for selective laser sintering, laser spectroscopy, maxillofacial surgery, and skin treatment.

Faster for cutting metals

Although the more precise control of fiber lasers makes them ideal for cutting through thin metals, CO2 lasers are the more preferred solution as a cutting tool for thicker materials. This is because CO2 lasers have better piercing performance and can cut through straight lines faster. They also typically leave smoother surfaces at the cut edges.

Cons

Sensitive optics

CO2 lasers rely on a complex array of mirrors for internally reflecting the photons released by the carbon dioxide molecules. This creates the amplification effect that allows CO2 lasers to emit a high power output. The biggest downside of relying on sensitive optics is that they can be easily misaligned or damaged due to external forces. This makes them less suitable for heavy-duty use. The frequent maintenance needs of CO2 lasers also mean more downtime which could lead to losses in high-volume production.

Less efficient

Compared to most other lasers, the 20% to 30% efficiency of CO2 lasers is not bad at all. However, they pale in comparison to the relatively new technology of fiber lasers. A fiber laser only consumes about a third of the power of CO2 laser with comparable power output. Considering the lower efficiency and the maintenance requirements of a CO2 laser, operating one may turn out to be more expensive in the long run than a fiber laser.

Which one should you get?

The dilemma between CO2 lasers and fiber lasers is an interesting one in that it represents a new laser technology with one that has pretty much set the foundation for all types of lasers. CO2 lasers have been around for decades and remain in wide use, demonstrating just how reliable it is as a manufacturing tool. On the other hand, fiber lasers boast of the power and efficiency improvements we have come to expect from more modern technology.

CO2 lasers remain popular because of two factors – versatility and cost. They have been used traditionally for a wide range of materials, owing to their demonstrably lower power output. They are also a lot cheaper, which makes them a more attractive option for small-scale industries.

Fiber lasers also have two distinct advantages – speed and efficiency. Although they require higher capital cost, fiber lasers have the potential to be more economical in the long run. This is because the higher throughput of fiber lasers provides greater production capacity. The efficiency boost will also generate savings when it comes to power costs.

Further advancement in fiber laser technology may eventually allow them to be priced more competitively with CO2 lasers. Until then, however, they will only be more practical for industrial applications meant to fulfill high-volume orders. For smaller industries or less frequent applications, the lower price of CO2 lasers makes them the more reasonable option.