How Much Does it Cost to Own and Use A 3D Printer?

Expect to spend an initial amount of $600 on buying an entry-level 3D printer and the initial stock of tools and supplies. After this, your recurring costs will depend largely on how frequently you use your 3D printer. The cost of additional supplies, maintenance, and power usage can range between $100 to $200 per year.

Whether you’re going into 3D printing as a hobby or a side business, it will be wise to anticipate significant expenses. These costs will include not just the 3D printer and the supplies, but also the cost of power use and maintenance of the hardware. To avoid surprises, let’s break down the usual costs associated with 3D printing.

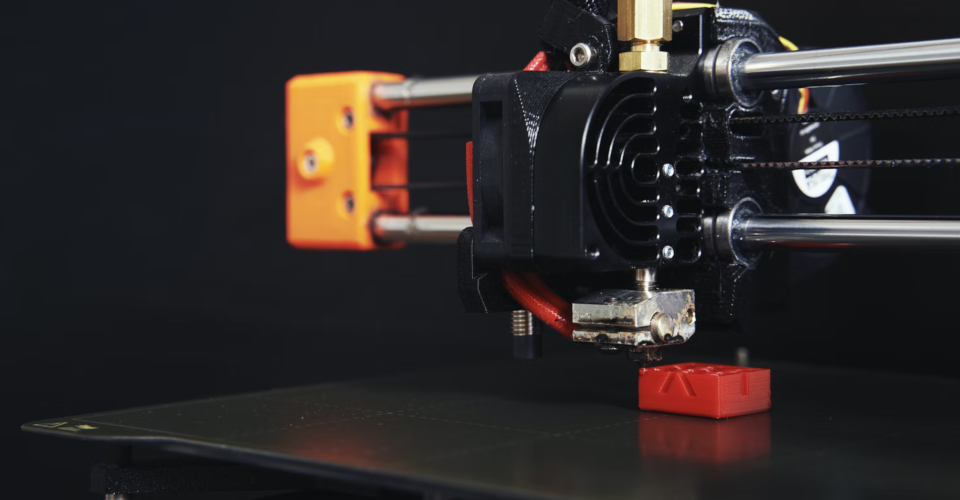

The 3D printer

The most obvious cost of 3D printing naturally goes to buying a 3D printer. In recent years, SLA and FDM printers have become incredibly more popular and more common. This means that there are now more options for inexpensive entry-level 3D printers using different technologies.

This also means that there is now a much wider range of prices for entry-level 3D printers. On one end, we have FDM and SLA printers that cost less than $400:

- ELEGOO Mars 2 Mono Resin 3D Printer

- ANYCUBIC Photon Mono Resin 3D Printer

- Creality Ender 3 Pro 3D Printer

- ANYCUBIC Mega Pro 3D Printer Kit

- FlashForge Adventurer 3 Lite FDM Printer

Each one of the printers on this list has been a mainstay in the 3D printing community and has been heavily recommended for beginners. A huge benefit of entry-level 3D printers is that they are typically small, making them ideal for workshops that have limited space. However, this also means that these 3D printers have smaller build volumes.

Even if you’re just a beginner, you don’t have to restrict yourself to inexpensive models. A great thing about this era of 3D printing is that it’s very easy to get into. 3D printers are specifically designed to be user-friendly even when they have advanced features. Popular 3D printers also have thriving online communities that users can get in touch with for help.

If you’re willing to spend more than $500 on a higher-end 3D printer, these are excellent options:

- ANYCUBIC Photon Mono X Large Resin Printer

- Flashforge Creator Pro 2 with Independent Dual Extruders

- Dremel DigiLab D320 3D Printer

These printers straddle the line between being hobbyist and professional models. They are larger and more expensive but not necessarily more difficult to use. These printers make good investments if you’re serious about getting into 3D printing and don’t want to get a 3D printer that might get outdated soon.

Of course, there are 3D printers that are much more expensive. If we move into the realm of professional 3D printers, you could look at spending between $2000 to $6000. This is not something to consider for beginners, so we’re sticking to our recommendation. If you’re just starting out, you can make do with a budget of $400 for the 3D printer.

Tools and supplies

You will find quickly enough that the 3D printer is not the only initial expense if you’re getting into 3D printing. There can be more than a dozen peripherals, such as tools and supplies, that you will need to have before you come up with your first project.

The list of necessary tools and supplies will depend greatly on whether you are printing with filament or resin. For clarity’s sake, we are making separate lists for each type of 3D printer.

Peripherals for FDM printing

Filament

Most 3D printers come with a few sample filament rolls but let’s be honest here – those will not last long and probably are not the best 3D printing filaments out there. To make the most of your experience, it would be good to buy new filaments that are in the material or color that you’re interested in. This makes you more invested in coming up with your first few projects.

Most 1-kilogram filament spools cost less than $25. You can find several high-quality filaments in this price range from trusted brands such as Hatchbox and Overture. You will also find that the cheapest filament types are those made of PLA, ABS, or PETG.

For your first foray into 3D printing, setting aside about $100 for a set of different filaments should get you through a few months. Make sure to get at least one spool of PLA in your favorite color, as this is certainly the easiest filament to print with.

Scraper and putty knife set

Removing a finished print from the build plate is a momentous occasion whenever you complete a 3D printing project. However, it can result in a disaster if you’re not careful and if you’re not using the proper tools. We recommend getting a scraper and putty knife set for this crucial step.

Silica gel

One of the most important rules of filament storage is to keep it away from moisture. This means that your filament spools should be kept in airtight bags or containers, ideally with some packets of silica gel. The great thing about silica gel is that it’s inexpensive and spent silica gel can be regenerated simply by drying them in an oven.

Tape and other adhesives

When you start dealing with filaments that are prone to warping, you will be thankful that you have some adhesives on hand. Acceptable adhesives range from blue tape, Kapton tape, glue stick, or hairspray. None of these are expensive so there’s no reason not to get all of them.

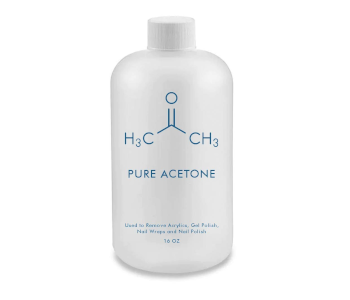

Acetone

Acetone is the ideal post-processing agent if you’re printing with ABS. Through a process called acetone vapor smoothing, you can make the surface of your ABS prints impeccably smooth with minimal effort. Acetone is fairly inexpensive so it would not hurt to have a bottle lying around, but keep in mind that this is still a flammable and toxic solvent.

Pliers

Supports are a natural part of 3D printing, particularly when you start printing more complex models. They are also quite annoying because you likely have to remove them manually. Different situations may call for different pliers, so we recommend just having a set of pliers ready.

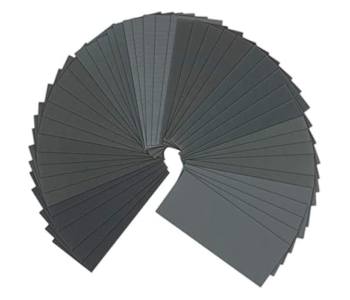

Sandpaper

Sandpaper is a staple tool in 3D printing, particularly in post-processing. It may be old-fashioned but sanding a 3D print smooth is still one of the most reliable techniques because of how much control it gives. It’s a good idea to have a set of sandpaper of different grit grades. They are fairly inexpensive.

White lithium grease

You will have to reapply white lithium grease on the linear rods of your 3D printer every few months, just to make sure that they are moving uninterrupted. A single tube of white lithium grease should last a few years.

PTFE tube

In a filament printer, a segment of PTFE tube sits between the extruder and the heater block. This allows for low-friction movement of the filament while also preventing “heat creep” that will disrupt extrusion. This PTFE tube inevitably gets worn down over time. When this happens, it would be nice to have a few meters of PTFE tubing that you can just cut segments off from.

Peripherals for SLA printing

Resin

Again, your new 3D printer might come with a bottle or two of resin, but you will eventually have to buy more stock. Photopolymer resin has gotten a lot cheaper in recent years. If you know how to store and recycle them properly, two 500-gram bottles should last you a long time. We recommend getting high-quality but affordable resin from ANYCUBIC or ELEGOO.

Isopropyl alcohol

You are going to need a lot of isopropyl alcohol (IPA) in resin printing. This will mostly be used for washing finished prints but is also handy for general cleanup of your working area. High-concentration IPA is more effective for washing off the excess resin, but keep in mind that this grade of IPA is not meant for skin contact. It would be a good idea to have at least 2 liters of IPA on stock.

Washing station

Once a finished resin print has been taken off the build plate, it needs to go to the washing station. This does not need to be anything fancy – a plastic contained deep enough to submerge your resin prints will do just fine. Ideally, this container should be sealed so you can shake the resin print around without worrying about leaks.

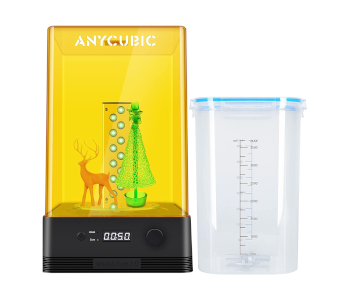

UV curing station

A UV curing station could be the most expensive you will get for your resin printer. This ensures the full curing of your resin print so that it becomes as strong as possible. Commercial UV curing stations some with a turntable in an enclosed chamber that has been internally lined with UV light. The cheapest ones you can get will cost around $50. The wash and cure station from ANYCUBIC is a lot more expensive but offers good value for money in terms of quality and ease of use.

Nitrile gloves and safety goggles

Whenever you’re working with resin, you must always protect yourself with a pair of nitrile gloves and good safety goggles. Photopolymer resin is a toxic compound and may cause irritation if it comes in contact with your skin or eyes. Keep in mind that gloves contaminated with resin must be disposed of, but make sure to cure the resin under sunlight first.

Spare FEP sheets

The FEP sheet in a resin printer acts as the clear boundary between the light source and the photopolymer resin. A single sheet typically lasts for a long time, but any kind of damage such as scratches or cloudy spots will warrant a replacement. Make sure you have spare FEP sheets on hand so that you can continue with your project even when you damage the sheet you are using.

With so many possible tools, accessories, and supplies that you will be needing, it’s tough to come up with a price estimate. To be on the safe side, we suggest setting aside about $200 for these peripherals. You don’t need to buy anything all at once, but make sure that you have the bare minimum before you get started. This can save you from the frustration of having to buy something online when something breaks down or if you run out of supplies.

At some point, you will have to buy new stocks of filament, resin, or other supplies. This depends largely on how heavily you use your 3D printer or how much you want to explore new materials. This is quite a rabbit hole that you can fall in. Setting aside $25 per month for new supplies is considered conservative, but should be acceptable without going overboard.

Power usage

As with any electrical equipment, your 3D printer will be consuming a fairly notable amount of electricity. In the case of filament printers, much of this power will go towards the heater block and the heated build plate. For resin printers, the power will mostly go to the array of UV lights that cure the resin.

3D printers also have an entire assembly of stepper motors, digital displays, fans, and control boards that require power. All of this hardware is activated for the entire duration of printing your model. The power draw of your 3D printer is another factor that you should consider in estimating the operational costs of 3D printing.

The amount of power that a 3D printer draws will depend on the specific model and how the printer is being used. For instance, printing with filament at 240 C will certainly consume more power than printing at 180 C. For this reason, the power rating of most 3D printers is given as a range.

From a random sampling of desktop 3D printers, we can assume a power rating range of 60 W to 250 W, or equivalent to 0.07 to 0.24 kWh. With an average electricity cost of 13.31 cents per kWh, this will translate to between 0.93 to 3.19 cents per hour. If you run your 3D printer for 8 hours per day and 5 days per week, you will only end up spending $2 to $5 per month or about $30 to $60 per year. This is actually not that expensive and is comparable to the power costs of running a desktop computer.

Maintenance

The cost of maintenance is an often-forgotten part of owning and running a 3D printer. Over time, 3D printer parts can break down or get worn out. Addressing this may be a simple task of replacing parts or having the printer repaired or serviced by the manufacturer.

Maintenance services are something you might want to consider when buying a 3D printer. Some manufacturers may offer extended warranty options that can help you save on maintenance costs, at least for the first few months of owning the 3D printer.

In terms of replacement parts, you likely will not be spending a huge amount as long as you use your 3D printer properly. The part that you will likely replace most frequently is the nozzle. Fortunately, brass nozzles are very cheap. We also recommend getting a few hardened steel nozzles should you decide to print with composite filament. There are nozzle sets available that have a combination of brass and hardened steel options.

You will also likely need to replace the print bed after some time. You can choose to either use a magnetic build plate or one that is made of glass. The glass option is a little more expensive but generally provides much better finish quality.

Overall, the maintenance costs of a 3D printer should not exceed more than $50 per year. It’s worth noting at this point that doing maintenance regularly is a great way to avoid more serious hardware breakdowns. Spending a few dollars to replace a few parts when needed might actually save you a larger amount spent on repairs further down the road if you had failed to maintain your 3D printer.

Final thoughts

3D printing is a field that has become a lot more accessible in recent years. A few years ago, you would not be able to buy an SLA printer for less than $1000. Nowadays, there are SLA printers and FDM printers from reputable brands that retail for less than $200.

If you’re going into 3D printing, then it’s worth knowing exactly how much you will eventually spend on this little hobby. It can be quite expensive, but you can save some money by doing proper maintenance of your 3D printer and using tools and supplies from reputable brands.