What Is Digital Woodworking?

Woodworking is an old-fashioned craft that has stood the test of time. Even with modern manufacturing technologies, there is nothing quite like the style and feel of a finely crafted piece of wooden furniture. Power tools may be a lot more common now, but these still require a great level of manual skill on the part of the woodworker.

This does not mean that modern technology has no place in the field of woodworking. The practice of digital woodworking is now starting to gain ground. What exactly is digital woodworking and what is its unique appeal?

Harnessing the power of CNC

In a nutshell, digital woodworking simply pertains to woodworking that relies heavily on Computer Numeric Control (CNC) technology. This means that most of the cutting and carving work will be done via automated tools that are controlled by a computer algorithm.

Integral to the concept of digital woodworking is creating a design via Computer-Aided Design (CAD) and processing the model using Computer-Aided Manufacturing (CAM) software.

Digital woodworking is really no different from any other CNC process. It also starts with an initial design phase where a 3D model is generated in CAD. The role of the CAM software is to take this 3D model and generate a G-Code algorithm based on it. This G-Code is basically a set of commands that tells the machine how the cutting tool should move.

Benefits of digital woodworking

For traditional woodworkers, relying solely on a digital model and algorithm may seem like a strange concept. If you work exclusively with hand tools, making the transition to digital woodworking may be very drastic. However, those familiar with power tools should easily see how practical the technology can be.

Versatility

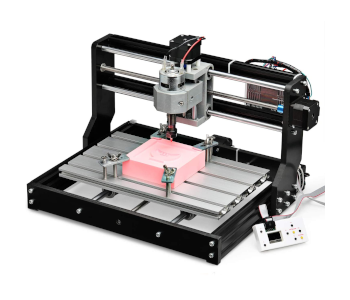

The standard equipment for digital woodworking is a CNC router. This has a movable rotating spindle where various cutting tools can be mounted. The motion of the spindle is controlled automatically with G-Code.

Even with just a CNC router, there are already a lot of intricate wooden products that can be made. It is possible to carve or cut into a wooden piece using a milling tool. The movable spindle can even be equipped with a laser for high-precision laser engraving and cutting.

Older CNC wood routers were typically restricted to working on a piece across a flat plane. This is no longer the case nowadays, as there are now routers that have provisions for rotary carving Such a feature looks like a standard CNC lathe but can produce designs that are not necessarily symmetrical to the axis of rotation.

Speed

With every step automated, a CNC process is significantly faster than doing the same piece manually. A huge speed boost comes from the fact that a CNC machine does not get tired – it rarely needs to take a break the same way that a human woodworker does. This makes digital woodworking so much more efficient than traditional woodworking methods.

Repeatability

As long as you have the G-Code algorithm set up and the piece is securely mounted on the router, there is hardly any reason for a CNC machine to make an error. This is ideal for when you need to do multiple copies of a single design. Digital woodworking is less prone to variability caused by human error.

Design freedom

Lastly, there are designs that are almost impossible to do using manual methods. This point is further emphasized when we consider the use of high-precision laser cutting and engraving. Although the detailed carvings made by digital woodworking can theoretically be done manually, a digital workflow still holds the advantage in efficiency and repeatability.

Collaboration

A digital woodworking workflow is founded on the use of digital 3D models as a reference for CNC machining. The great thing about the digital nature of 3D models is that they can be shared as you please. This means that a 3D model can be sent to another woodworker halfway around the world, who can then recreate the design with a reasonable level of accuracy. This eliminates the need to send meticulously measured blueprints.

In most cases, a finished piece will still require a bit of manual handling. After all, furniture still needs to be assembled, sanded, and painted before it can be considered a finished product. A CNC machine is just another addition to the array of tools that a woodworker can use.

The importance of design

In traditional woodworking, the valued skills are those that pertain to making complex geometries – perfectly fitting dovetail joints, smooth curved surfaces, or columns with captive rings. These require intimate knowledge of handling hand tools and power tools.

In the realm of digital woodworking, design is king. Developing design skills also requires experience. You may not have to pore over your CNC machine but on a CAD platform. Coming up with a good design doesn’t just involve creating a model that looks nice on the screen. The model must also be made in consideration of the limitations of the CNC machine.

Can the jig move precisely enough to create the small details in the model? Is the geometry of the model feasible on the CNC router or does the piece need to be mounted in a creative manner? These are small details that can be easily neglected in favor of a nice-looking design.

Digital woodworking enthusiasts have described the design as the “secret sauce” of the craft. Indeed, CNC machines are almost equally capable of the same things. Being able to come up with creative and innovative designs will then be the distinguishing factor in such an industry. This demonstrates that even in a process that is so heavily automated, the human touch of design is still the most valued.

Final thoughts

Digital woodworking is pretty much just a fancy name for woodworking using CNC machines. The name is apt, considering how heavily it relies on digital design platforms.

One characteristic of woodworking as a craft is that it cannot truly do away with manual steps. You may be able to carve a piece via CNC, but it still needs to be painted or finished by hand. Digital woodworking simply combines technology with a time-tested craft. It does not take away the soul of woodworking – it’s simply a tool that makes the process more efficient.