Diode Lasers Vs. CO2 Lasers – Which One is Best for Laser Engraving?

In recent years, laser engraving technology has transitioned from being purely for industrial use to a craft that hobbyists can explore. We can now buy fairly inexpensive laser engraved products made of paper, wood, or leather.

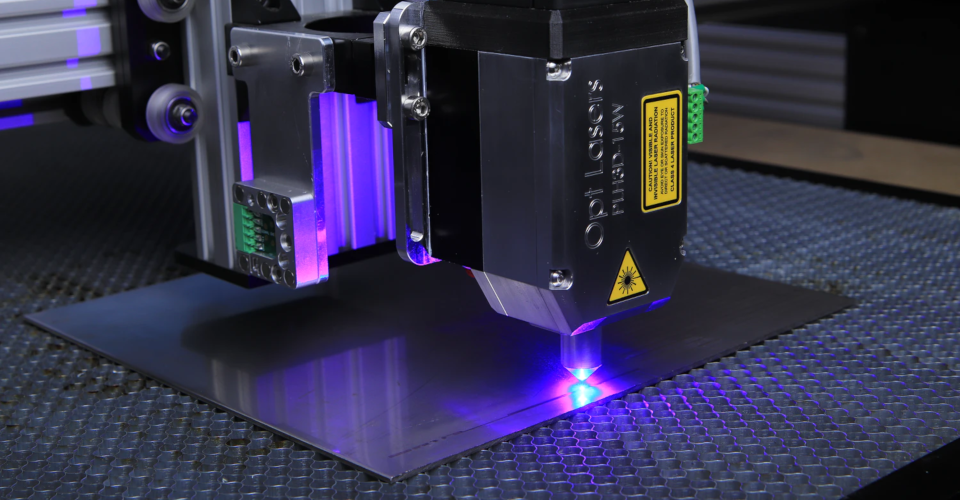

This new trend has been made possible mostly through the use of inexpensive diode lasers. What exactly are these diode lasers and how do they work? How do they compare to CO2 lasers – another laser technology that was quite popular for hobbyists?

What are CO2 lasers?

We have already covered the basics of CO2 laser technology in a past article comparing it to fiber lasers, so let’s just do a brief summary here. A CO2 laser has a discharge tube filled with gases as its active laser medium. Despite the name, the discharge tube is not just filled with CO2 – it is combined with nitrogen and very small portions of helium, hydrogen, and xenon.

An electric current is introduced in this gas discharge tube, resulting the addition of energy into the nitrogen molecules. These molecules vibrate because of the energy which is then transferred to the carbon dioxide molecules via perfect resonance. When the energized carbon dioxide molecules come in contact with helium, excess energy is released as photons.

The photons from the discharge tube go through a series of internal reflectors to accumulate enough energy to engrave or cut through most materials. These mirrors are typically made of either silver or gold. The wavelength and intensity of a CO2 laser can be adjusted by controlling the isotopic ratio of carbon and oxygen atoms in the discharge tube.

What are diode lasers?

The central element of a diode laser is the semiconductor diode. This is more specifically a p-n junction diode made of one p-type and one n-type semiconductor. The p-n junction acts like a turnstile that allows electrons to flow across the barrier.

A laser diode typically uses semiconductors made of alloys of aluminum or gallium arsenide. Electrical current is supplied through the diode, inducing the flow of electrons through the p-n junction. These electrons combine with holes on the other side of the junctions, in turn releasing excess energy in the form of photons.

The gap between the two semiconductors acts as the “mirror” that magnifies the intensity of the photons. The photons bounce back and forth across this gap and also collide with other incoming electronics. This “resonance” helps produce even more photons. It takes several hundred collisions to attain the desired optical gain in a diode laser.

In more complex applications, several semiconductor diodes can be stacked together. The multiple beams from these diodes can be focused into a single beam, making the output considerably more powerful. This also makes it possible to create multiple lasers with different wavelength values.

CO2 laser – Pros and Cons

Of the two, CO2 lasers are considered the more appropriate for heavy-duty applications. CO2 lasers are fairly common in industrial settings, especially for cutting through metals and glass. Here are some of the benefits and drawbacks of using CO2 lasers:

PROS

More powerful

When it comes to raw power, CO2 clearly holds the advantage. The output of CO2 lasers ranges from 25 W to a maximum of up to 400 W. CO2 lasers can cut through wood, acrylics, glass, and certain metals.

With a higher power output, CO2 lasers are also able to cut or engrave through materials faster. This is valuable in an industrial setting where productivity and quick turnover are critical performance indicators. For this reason, it is very common to see CO2 lasers in industrial manufacturing facilities.

CONS

Larger footprint

CO2 lasers are not compact. Aside from the long glass tube that the laser needs for optical gain, a CO2 laser also requires a cooling mechanism and external shielding. For this reason, substantial workspace needs to be set aside before a CO2 laser can be used. Applications with a higher power requirement will also need a larger workspace on account of a larger gas tube.

Fragile construction

Aside from being quite bulky, the CO2 laser is also very fragile on account of having an assembly of very tiny and intricately positioned mirrors. These mirrors must not be removed from alignment, lest the laser stop functioning as intended. Moving a CO2 laser around frequently is not considered good practice because of these characteristics.

More expensive

With a requirement for high-precision engineering, CO2 lasers are typically more expensive than diode lasers. This is another huge reason why CO2 lasers are not normally used for hobbyist applications or in small manufacturing businesses.

Diode laser – Pros and cons

To demonstrate just how simple diode lasers are, the typical laser used in a standard laser pointer is a low-energy diode laser. That should already tell you how diode lasers are different – they are cheaper, smaller, and can be powered by a small battery.

PROS

Less expensive

Nowadays, you can buy a standalone diode laser kit for less than $200. In comparison, a CO2 laser engraving kit will cost at least close to $500. This has made diode lasers quite popular in the hobbyist community, or even for those who want to start small enterprises.

Compact, lightweight, and robust

Diode lasers are very small and light, making them the perfect candidates for DIY projects. They are commonly found in 3-in-1 machines that combine a laser engraver with a 3D printer and CNC machine.

Portable laser engravers are also slowly becoming popular nowadays, all of which are based on diode laser technology. It also helps that diode lasers are quite robust – the regular movement of a diode laser is not a problem since its semiconductors do not need to be aligned perfectly to work.

CONS

Not as powerful

The biggest tradeoff of using a diode laser is that it has significantly low power. A single diode outputs a maximum of 10W. While stacking diodes is possible, it is not common practice for laser engraving.

Cutting through paper or balsa wood or engraving in leather are not problems but working with metal or thicker wood might be less realistic. If you’re working with more challenging materials, then expect to do several passes and spend a long er time with a CO2 laser.

Limited applications

Settling with a diode laser means simply accepting that you cannot engrave or cut through many materials. Diode lasers do not have enough power to engrave metal or glass unless some coating has been applied to them. Diode lasers also struggle with any surface that is glossy, transparent, translucent, or painted completely white.

Which one should you get?

Choosing between the two is a simple matter. Diode lasers are cheaper, smaller, more robust, and easier to use. This makes diode lasers a lot more practical for casual use, or if you just want to take on laser engraving as a side hobby. You can also start a small laser engraving business with a diode laser, although you will have to focus on leather or paper goods. If you already own a 3D printer, you can convert it into an automatic laser engraver using a diode laser and with some software changes.

A CO2 laser is more appropriate for professional applications. Owning and operating a CO2 laser can get very expensive, so it really should be done if there’s a chance for profit or in aid of research. A CO2 laser is finicky, fragile, takes up a larger workspace, and requires a considerably higher level of skill to operate. Using one also requires more stringent safety measures because of the power levels you will be requiring.

If you’re buying a CO2 laser for its capabilities, then a CO2 laser is a worthwhile investment. A diode laser, on the other hand, is more suitable for DIY hobby projects.

Final thoughts

Laser engraving is slowly becoming popular as a hobby, but it can still seem intimidating for most people. This can also be a good thing – after all, even low-powered diode lasers can be potentially harmful if used without the proper safety measures.

Whether you get a diode laser or CO2 laser, keep in mind that you will be dealing with a narrow ray of photons with very high energy levels. Any laser can easily start a fire or cause injury to a person. Just as with any fancy new technology, safety is of utmost importance before you start using any type of laser engraving machine.