Electrically Conductive Adhesives: What It Is and Where to Buy

Most of us are familiar with the idea of soldering together electrical components to create not just a physical bond between them, but also a conductive connection. What is a lesser-known topic is the use of electrically conductive adhesives in cases where the soldering technique just won’t do.

What is an electrically conductive adhesive, and what is it made of? What are its common applications? If, after reading this article, you realize that you could use a conductive adhesive for your next project, then we’ve also come up with a helpful list of some of the best conductive adhesives that you can buy.

What is an electrically conductive adhesive?

As the name implies, an electrically conductive adhesive is an adhesive made of conductive particles suspended in a sticky compound. With about 80% of the mass of the adhesive made of the conductive particles, they are spaced closely enough to each other to allow a substantial current to pass.

There are two broad classifications of conductive adhesives based on how they conduct electricity: isotropic and anisotropic. An isotropic adhesive conducts electricity equally in all directions, while an anisotropic adhesive restricts the current flow in one direction only.

The composition of conductive adhesives can vary greatly from one product to another. The base adhesive is typically a 2-component epoxy, although acrylate and polyester are also quite common. The conductive component plays a huge role in determining the cost of a conductive adhesive: inexpensive ones use iron, which has poor conductivity, while the most expensive ones use either silver or copper.

Aside from an obvious effect on the price, the combination of adhesive base and conductive material also affects the physical and chemical properties of a conductive adhesive such as its viscosity, mechanical strength, thermal expansion, reaction to humidity, and its curing process. All these things need to be considered when choosing a conductive adhesive based on your application.

Applications of electrically conductive adhesives

Speaking of applications, how are electrically conductive adhesives used anyway? What are their advantages over old-fashioned soldering?

1. Binding temperature-sensitive electrical components

The main application for conductive adhesives across many industries is for holding in place electrical components that are sensitive to high temperatures. With this limitation, soldering as a means of adhesion will be instantly ruled out. A conductive adhesive is a convenient, safe, and strong alternative to soldering.

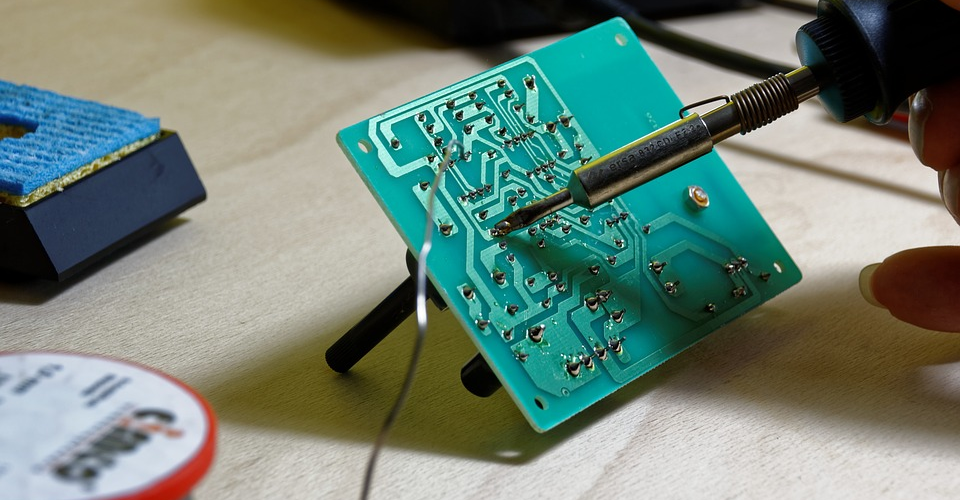

The most common application of conductive adhesives in the electronics industry is in the manufacture of printed circuit boards (PCBs) where either the components or the substrate is temperature-sensitive. There are also a bunch of common electronics that can be damaged or warped if exposed to the high temperatures of solder such as RFID tags, LCD displays and touch panels, and LEDs.

2. Creating a makeshift Faraday cage

One of the more creative uses of a conductive adhesive is making your own inexpensive makeshift Faraday cage, a container that isolates its contents from all sources of electromagnetic signals. A Faraday cage is usually employed for technical or scientific measuring devices that are very sensitive to electromagnetic noise or interference.

Normally, a Faraday cage is made out of a conductive solid material, such as a metal mesh or a box layered with aluminum foil. If you’ve got a good amount of conductive adhesive handy, then you can turn any container into a Faraday cage by making your own conductive mesh. Just make sure to keep the spaces small enough to block those high-frequency signals!

3. Grounding samples for scanning electron microscopy (SEM)

Scanning electron microscopes work by emitting a pulse of electrons towards a sample and recording their reflections, resulting in a highly detailed image that no light microscope can replicate. It’s an invaluable technology that has been used in various scientific and technical fields.

A challenge in SEM analysis is in ensuring that the sample you are analyzing is grounded to prevent any electrostatic accumulation from the bombardment of electrons. A dab of conductive adhesive fulfills this purpose, simultaneously grounding the sample and keeping it fixed on the analysis platform.

The top 4 best electrically conductive adhesives

1. MG Chemicals 2-Part Silver Epoxy Adhesive

If you need a conductive adhesive that can create enough volume to bridge a gap, then an epoxy-based adhesive is exactly what you’re looking for. This two-part epoxy from MG Chemicals has very good conductivity, mixes in a convenient 1:1 ratio, and provides a total 10 minutes of workability. MG Chemicals also sells a variant of this epoxy with 4-hour working time that is suitable for doing large-scale jobs.

It takes about five hours for the epoxy to fully cure in room temperature. You can cut that time down to as low as 15 minutes by exposing it to higher temperatures. When fully cured, the adhesive has very good binding properties and can withstand thermal and mechanical shocks. The separate epoxy components can be safely stored at room temperature and have a long shelf life.

2. MG Chemicals 9410 1-Part Conductive Adhesive, 3-mL Dispenser

A two-part epoxy that you mix and apply like putty is great for filling in large cracks or for other applications that don’t require a delicate application process. However, if you’re working with PCBs or small electrical components, you need an adhesive delivery system that’s a bit more refined and precise. This is the exact purpose of this one-part adhesive by MG Chemicals that is packaged in a syringe with a fine tip.

One disadvantage of a one-part epoxy is that it usually requires exposure to high temperatures to be fully cured. In the case of this product, a minimum temperature of 90 °C will be needed. If the components you are working with cannot withstand this heat, then you simply need to get another conductive adhesive.

Although the product is advertised as having a shelf life of 4 months at room temperature, it’s easy to lose track of how it’s stored, and you could end up with a syringe full of cured epoxy just when you need it. For this reason, we recommend storing this epoxy in a freezer or refrigerator.

3. MG Chemicals 9400 1-Part Conductive Adhesive, 3-mL Dispenser

This product is essentially the same as the 1-part adhesive above, but this version only needs exposure to 70 °C to cure. If the components you’re working with are too sensitive to heat, then this is a good alternative. It also comes in a small syringe with a narrow tip, allowing you to apply them delicately and precisely.

4. Sciplus 400 Electrically Conductive Soldering Gun Wire in A Jar

Despite a cartoonish packaging, this “soldering gun wire in a jar” from Sciplus 400 looks like it has potential. It claims to be an alternative to a soldering iron in situations where you simply don’t have one on hand or can’t be bothered to set it up. It can conduct current in low-voltage circuits and cures in about 24 hours.

The product itself is a black, semi-viscous paste that can be applied using a brush or a toothpick. It works fine for application to thin wires but does not create enough volume to fill in gaps or cracks. When fully cured, the adhesive also does not have a lot of durability, cracking and falling apart with a small amount of stress. Thus, this “wire glue” isn’t something we would recommend for moving parts.

Another reason why we picked this product last is the fact that it’s so cheap that it doesn’t even tell you what its adhesive agent or conductive materials are. With no information to go on, it’s very hard to predict how this adhesive will perform or under what circumstances it can ideally be used. If we had to hazard a guess, we would say that the glue’s conductive material is graphite, which explains why it can only accommodate such a small current.

Final thoughts

An electrically conductive adhesive is a great tool to have in your kit for when you just want to do a quick fix of your electronics, or in situations where soldering is simply out of the question. They are mostly used in scientific or industrial scenarios, which means that the best products aren’t exactly the kind of stuff that you can just buy online. If you’re considering using a conductive adhesive, then we recommend splurging for the best one you can get – something epoxy-based and infused with silver particles for maximum conductivity. It can get pricey, but you really get what you pay for.

Such a product is useful but one that cures at around 60f would suit most home users.

I need to solder where a soldering iron, flame, won’t go and a normal soldering iron is inadequate. A blob of this stuff on each surface(inside a starter motor tube) to provide an earth path is what I need.