How Much Electricity Does A 3D Printer Use?

While 3D printing is certainly a fun little hobby, there’s no question that it can also get pretty expensive. Between the cost of the printer and the plastic filaments, you can easily spend several hundred dollars just to get started. One other recurring cost we should not ignore is the cost of the electricity that a 3D printer consumes.

Whether you 3D print for fun or as a business, the money you spend on electricity is something you need to keep in mind. Just how much electricity does a 3D printer use and what can you do to keep your power expenses low?

First step: check your printer’s power rating

As with any electrical device, your 3D printer should have a power rating. For instance, a 3D printer that requires a 30 A 12 V will draw up to 360 Watts of power (Power = Current x Voltage). This is a very high figure, but only because this is the maximum power that this particular 3D printer can draw.

There could be a very significant difference in power draw if you’re printing at high temperatures, high speeds settings, or with a heated bed. Between different models, however, you can expect printers with larger build platforms to consume more power, as well as those that can print at higher temperatures.

What factors contribute to how much power 3D printing consumes?

If you’re interested in determining specifically how much power your 3D printer requires, then the best way would be to use an electricity usage monitoring tool. These tools act as an interface between your 3D printer and electrical socket, giving you an accurate measure of the volts, amperes, and wattage that the 3D printer consumes. The Kill A Watt Electricity Usage Monitor from P3 is a good example.

It would be impossible to isolate any single part of the 3D printing process and check how it contributes to a printer’s power consumption. What we can do instead is to take stock of these factors and infer how much electricity they are using.

Heating at the hot end

One of the most power-draining parts of a 3D printer is the hot end, specifically the part of the nozzle that melts the filament. Exactly how much power this process consumes depends on what temperature you set it to, which is also based on the type of filament you’re working with. If you work with a lot of high-temperature filaments, such as Nylon or ABS, then you’re probably using up a good deal of electricity on this part alone.

Heating of the print bed

The temperature of the print bed goes hand-in-hand with the nozzle temperature. This is a measure that improves bed adhesion and prevents warping, which is one of the perennial problems when working with high-temperature filaments.

There are two factors to consider when assessing the power consumption of a heated bed – the temperature setting and the size of the bed. The temperature also depends on the type of filament you’re printing with. The bed size is a function of your 3D printer. The larger the bed, the more power it will take to maintain it at the set temperature.

Heat losses

The components of a 3D printer can go to temperatures above 200 °C. They also have to stay at that temperature, so any heat losses to the environment will have to be compensated for by the heating element. This is another problematic affair for high-temperature 3D printing, as a hotter nozzle and print bed will inevitably also have higher heat losses. If there’s a way to minimize heat loss, then you could save a great deal in power costs.

Stepper motors

There are two important sets of stepper motors in a 3D printer: those that control the extruder gears and those that control the movement of the nozzle. While these motors are very small and consumer little power, they also have to constantly run for the several hours it takes to finish a single 3D printing project.

Control board

The control board or the “brain” of the 3D printer is made up of multiple electrical components that help control the temperature of the printer, the location of the nozzle, how the extruder gears run, and various other trivial tasks. Despite the importance of this function, the control board doesn’t really use up a lot of power.

The conclusion we can derive from this little exercise is that most of the power that a 3D printer consumes goes towards the heating of its nozzle and print bed. While not surprising, this fact also gives us an inkling of how we can possibly reduce the power consumption of our 3D printing projects.

Comparing the power consumption of different 3D printer models

Since it would be impossible to quantify the exact power consumption of a 3D printer without specifying a model, we’ll take a look at how much power different 3D printer models consume and how these translate into costs.

Let’s start with the Monoprice Mini Delta, a very small and inexpensive Delta-type 3D printer that has proven quite popular with beginners. Among its distinguishing characteristics are the small build platform and a print head controlled by three stepper motors. According to the data, the Monoprice Mini Delta only consumes up to 45 Watts during preheating of the bed and the nozzle. The power consumption slightly increases to 60 W during printing, likely due to the effect of the stepper motors.

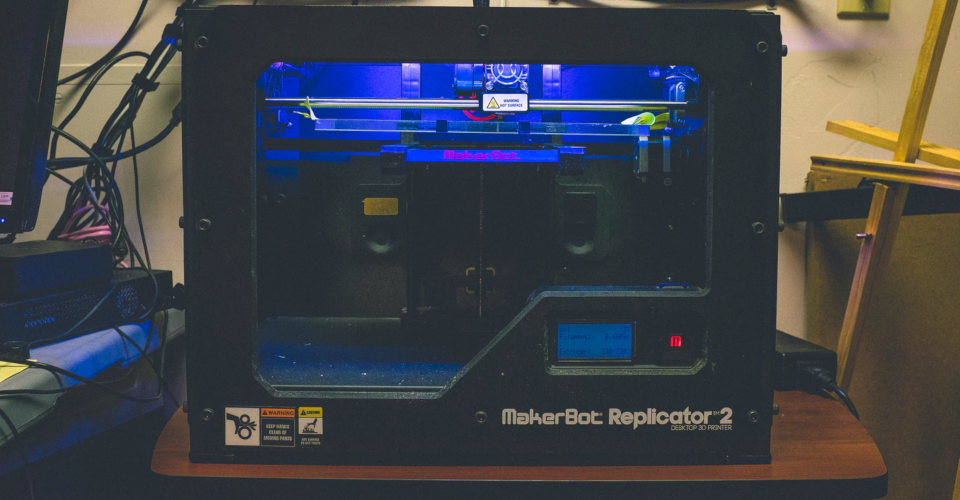

To provide a contrast, let’s look at the power consumption of the Flashforge Creator Pro. This is a much more expensive 3D printer with a larger print bed, a rigid metal frame, and an integrated enclosure. Preheating the large print bed took a staggering 300 W of power, while the nozzle required a slightly lower 280 W. The enclosure proved to be very instrumental in keeping the heat loss down and helping the printer stabilize to about 250 W of power while printing.

The two 3D printers we referenced here give us a useful range for how much electricity models of different levels of sophistication can consume – from 60 W to 250 W during printing. Translated to kWh, this range corresponds to 0.07 to 0.24 kWh.

This also allows us to compare the power consumption of 3D printers to other devices we have around the house. For instance, a typical desktop computer consumes about 1.05 kWh – more than four times the power consumption of the Flashforge Creator Pro.

Based on data on electricity rates from April 2020, the average US residential customer pays 13.31 cents per kWh. This means that you will only pay roughly 3.2 cents for every hour that you use the Flashforge Creator Pro. The numbers for the Monoprice Mini Delta are even more pleasantly surprising – you pay less than 1 cent for every hour of use.

These numbers would probably come as a relief for 3D printing enthusiasts, especially those who leave their printers running for hours on end. While it’s no excuse to wantonly waste electricity, it’s still comforting to know that you’re not taking a huge hit on your recurring expenses just because you’ve gone into 3D printing.

Tips to reduce your 3D printer’s power consumption

Despite coming to terms with the fact that you aren’t likely adding a huge amount to your power bill just because you’re using a 3D printer, many of you will probably still appreciate any tips on how you can reduce that power consumption.

1. Use a printer with an enclosure

As our analysis of the Flashforge Creator Pro has shown, the presence of a print bed enclosure can significantly reduce the power consumption of a 3D printer during the printing process. This becomes even more pronounced if you are printing with a filament that requires high temperatures for both the nozzle and the print bed. If you’re using an inexpensive printer that does not have an integrated enclosure, then you can simply make one yourself using a couple of plastic sheets and wooden frames. There are lots of tutorials online for DIY 3D printer enclosures.

2. Shorten the printing time

Time is a factor that we haven’t talked about much but is certainly one of the most essential in determining how much power a 3D printer consumes. If you can cut down the printing time of your project, then you can significantly reduce its power costs.

There are several ways to achieve this goal, but there are two that are particularly effective: increasing the printing speed, and printing with thicker layers. Obviously, this isn’t the type of advice that you can take in a vacuum. You’ll have to consider other factors such as printing temperature, type of filament, and the level of quality of the finished product when making such adjustments.

3. Print with high-temperature filaments only if necessary

Experiment with different types of filament materials is a natural part of 3D printing but sticking with those that require very high printing temperatures can get pretty expensive in the long run. Not only do these require more heat in the nozzle but also a similarly hotter print bed. A difference of 30 to 40 °C may not sound like much, but every little bit counts – at least, depending on which perspective you take.

If you’re concerned about consuming too much power on your 3D printer unnecessarily, then you might want to stick with low-temperature filaments like PLA if you’re printing just for fun. Not only will PLA deliver savings on power, but it’s also the more environmentally conscious filament choice because of its biodegradable nature.

Final thoughts

Giving some thought to how much power each of our electrical devices regularly consumer is just part of being a responsible consumer. This same principle applies to 3D printers. With 3D printing quickly becoming a hobby for more and more people, now is the perfect time to be more conscious about how much power 3D printers consume.

It’s a nice surprise to discover just how power-efficient 3D printers are, especially compared to computers and TVs we normally have around the house. Still, that’s no excuse to not make any efforts to reduce the power consumption of our 3D printers. With responsible use, we can keep our power costs down while doing our duties as responsible citizens.