How to Finish Your PLA Prints – Easy Techniques

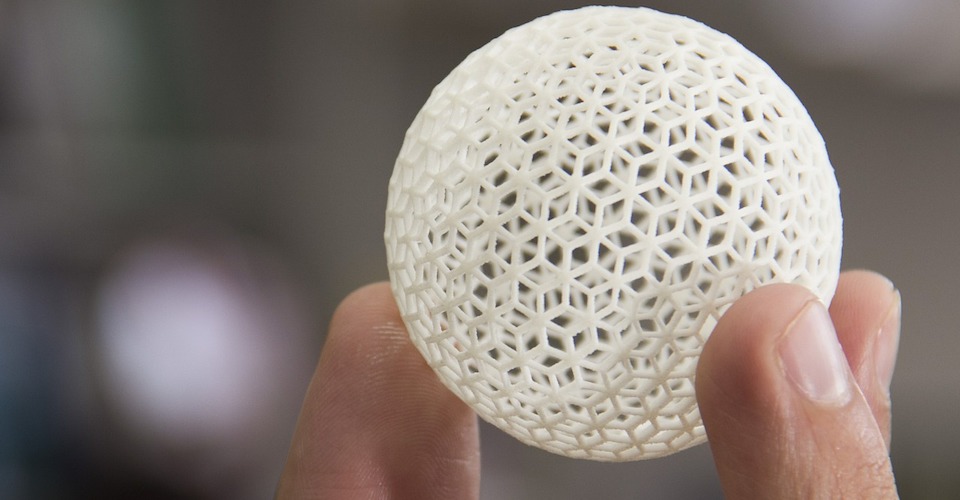

3D printers have come a long way in the last couple of decades. Nowadays, 3D printers are smaller, faster, more flexible, and easier to use than ever. Almost all of the desktop printers in use nowadays are of the Fused Deposition Modeling (FDM) type, which has become popular because it is cheap and relies on simple operation principles. However, even the best FDM printers have not yet overcome one of their biggest limitations – prints coming out with visible layer lines.

Fortunately, there are several ways for you to achieve a smooth finish in your PLA print. Depending on how much time and effort you’re willing to spend on the finishing process, it’s possible to get finish quality ranging from mere removal of layer lines to a glossy, glass-like surface.

What is PLA and why do you need to finish a PLA print?

Polylactic Acid (PLA) is one of the two most popular filament materials used for FDM printing. It’s cheap, easy to use, versatile, and available in a variety of colors. It’s quickly solidifying its role as the default material for 3D printing due to its odor-free, low-warp and environment-friendly characteristics. PLA is made from corn starch, a fully renewable source, and is manufactured using less energy compared to petroleum-based plastics.

FDM technology is based on the buildup of successive layers of filament material to form a three-dimensional object. Although tweaks on the 3D printing software can be made to reduce the layer height of a print, it is still impossible to create a print completely devoid of layer lines right out of the FDM printer.

While an unfinished PLA print is still perfectly functional, its visual appeal can be massively improved even with the most basic finishing techniques. If you are attempting to do 3D printing for any commercial purpose, then mastering these finishing techniques will be a valuable addition to your skillset.

PLA finishing methods

Petroleum-based materials, such as ABS, have very easy and passive methods of finishing that involve vaporizing of a suitable solvent. Unfortunately, PLA lacks this quality of convenient solubility. This means that the finishing techniques for PLA are a little more involved. If you want to get a high-quality finish with your PLA print, then be ready to put some elbow grease into it.

1. Sanding

Any decent PLA finishing job starts with sanding. Sanding removes the outermost layer of PLA material, greatly reducing the number of visible ridges on the surface of the print. For best results, you need to use multiple grits of sandpaper. Start with a coarse 200-grit paper, then move up to 400, 600, 800, 1000, 1500, 2500 up to 3000. Although you can skip some of the grit grades in this sequence, a professional-grade finish will require these many steps.

When sanding, it is important to maintain a circular motion so that the finish does not come out with a visible direction bias. You also need to resist the urge to sand too fast, as the heat generated by friction could be enough to melt the PLA material. This also means that sanding using a machine is out of the question.

We also recommend using a ‘wet sanding’ technique. To pull this off, you’ll need waterproof sandpaper. By slightly wetting the sandpaper, you keep the PLA material cool and prevent it from melting. The water also helps to mobilize the particles that come loose during the sanding process, removing them from the surface of the print and making the process faster and more efficient. A wet sanding method can be used no matter what grit size of sandpaper you have.

The more time you spend sanding your PLA print, the smoother finish you will get. Don’t worry too much, though, as you’ll need to spend less and less time as you go from one grit size to the next. Be mindful of small details in the print, so your finish comes with consistent quality.

2. Polishing

Even with your best efforts, layer lines cannot be completely erased by mere sanding. The result of all the hard work sanding your PLA print will only really pop after you apply a polishing agent. Any high-quality liquid metal polish will do, such as the ever-reliable Brasso Multi-Purpose Metal Polish. To apply the polish, simply apply a small amount on a soft cotton cloth and rub this into the surface of the 3D print in small circular motions. The metal polish will fill any micro-striations in the 3D print’s surface.

If you can’t find a liquid metal polish, then solid wax-based polishing compounds will do nicely. To use a solid polisher, simply rub a piece of soft cloth on the bar. A very thin layer of the wax material will adhere to the cloth, which you simply need to rub on the surface of the 3D print. Solid polishing compounds are also highly compatible with buffing wheels which can greatly speed up the polishing process. If you decide to use a buffing wheel to finish your PLA print, it’s best to use it at the lowest speed setting to reduce friction with the plastic material.

Repeat application of the metal polish until the surface feels sufficiently smooth and looks shiny. The last step to get a mirror-like finish is to buff the surface of the print. This is simply done by rubbing the surface with a piece of soft cloth that has none of the metal polish. You should see a prominent improvement in the smoothness of the surface as you continue buffing.

3. Priming

A third option for finishing your PLA print is to use a primer spray paint in combination with the sanding technique. A cheap can of Rust-Oleum works best for this method. After you have finished sanding using the highest grit sandpaper, simply spray a thin and even coat of Rust-Oleum on your print. This material will fill in all the smalls paces in the surface of the print and will dry in just a few minutes.

The advantage of using Rust-Oleum is that it can be sanded to get a smooth finish. After the coating has dried, simply sand the renewed surface to you’ll see how smooth the Rust-Oleum compound is when sanded. You don’t need to stop at a single layer. If you find that some areas of your print are rougher than others, you can spray an additional layer of Rust-Oleum on those areas and sand again to finish.

4. Heating

Heating is a rarely done method of PLA finishing as it requires a lot of skill and finesse. As the technique obviously uses a significant amount of heat, doing it wrong can easily lead to completely ruining your PLA print.

Heat finishing uses a heat gun, such as this 1550-watt model from DeWalt. Before proceeding to the heat gun step, we still recommend completing the whole sanding process. Sanding reveals much of the plastic in the surface of the 3D print, making smoothing by heat faster and more even.

To finish your 3D print, simply point the heat gun at the object and maintain slow and constant motion. It is best to set the temperature of the heat gun only slightly above PLA’s glass transition temperature, at around 80 to 100 °C. Don’t allow the heat gun to stay pointed at any single area, as prolonged exposure will easily melt PLA.

Although PLA is well-known for being odorless when heated, any heat treatment will inevitably produce fumes. When heat finishing your PLA print, make sure that you are doing it in an open or well-ventilated area.

5. Epoxy Coating

The downside of relying on a finishing technique that requires sanding is that it takes a lot of time. Although sanding small, handheld items will only take several minutes at most; larger prints might take hours. Applying multiple coats, waiting for them to dry, and sanding again, can be an excessively long process that is impractical when producing multiple 3D printer parts.

If you are pressed for time, then it might be best to use a brush-on epoxy coating such as the XTC-3D from Smooth-On. This product is made of two liquids that, when combined, create a resin-like material that can be brushed on the surface of your 3D print. This material fills in all the gaps in the surface of the print and self-levels so that no brush strokes will be visible. It takes 4 hours for the material to cure, after which it forms a smooth, hard, and impact-resistant coating.

The coating produces by XTC-3D is also one of the most workable materials you can have, as it can be readily sanded, primed, and painted. It is also one of the most versatile finishing products available today, as it can also be used with ABS, SLA, powder-painted parts, urethane foam, wood, plaster, paper, and fabric. The XTC-3D might be a little expensive, but the time and effort you’ll save, as well as the versatility of the material, are well worth the price.

Final thoughts

3D printing can start as a fun little hobby, and you’ll probably start out making prints that are far from perfect. As you refine your skills, you will develop higher expectations for the quality of your prints. However, the skill of adjusting the printing speed and layer thickness of your 3D printer can only take you so far. Even the best 3D printers still produce prints with unsightly layer lines.

To truly take your 3D printing craft to the next level, you will have to learn and master several finishing methods. Take note that the finishing methods outlined above are only applicable for PLA – other filament materials will require totally different methods.