Can 3D Printed Items Be Food-Safe?

Yes, 3D printed items can be food-safe but it’s going to take a lot of extra work. You will have to make sure that both your material and 3D printing process is food-safe, and that the product is finished according to food safety standards.

One of the most compelling benefits of 3D printing is that it can be used as an alternative for traditional manufacturing. This could involve applications in food containers, utensils, or other items that come in contact with food. This begs the question – is it possible for 3D printed items to be food-safe? What are the precautions needed for food-safe 3D printed products?

Defining food safety and its importance

Before we dive deep into a discussion of food safety, we must first provide technical definitions of a few key terms:

- Food-grade material refers to any material that is safe for human consumption or permitted to come in contact with food.

- A food-safe item refers to an item made from food-grade material that will not create a food-safety hazard by meeting the specific requirements of its intended use.

Food grading is important for items and surfaces that are intended for frequent or long-term contact with food. These include sealed containers, mugs, cups, utensils, or plates. A key concept to remember is that particles from these surfaces can migrate to the food because of long-term contact or exposure to extreme temperatures or cleaning agents.

If we’re going for an even more technical definition, we will have to refer to the FDA Food Code. Being compliant with FDA food grading is a lot more complex. It involves additional requirements including that the surface should not impart colors, odors, or tastes to food and that it should be resistant to chipping, pitting, scratching, distortion, or decomposition during normal use. It should also be able to withstand repeated washing cycles.

For this article, we are assuming that you do not intend to create food-safe items for FDA certification. Instead, we will limit our scope to how you can make your 3D printed items food-safe for personal use or as gifts to your family and friends. Selling 3D printed items for food contact will likely open up an entirely different can of worms.

Factors that affect food safety

Before we can 3D print food-safe items, we must first understand the different elements that can influence food safety. Just like in any other manufacturing process, certain modifications have to be made in 3D printing to ensure that finished products are safe for long-term food contact.

Base polymer

Food-safe plastics have been well-defined in traditional manufacturing. Common examples include polyethylene terephthalate (PET), polyethylene (PE), and polycarbonate (PC). Unfortunately, the selection is much smaller in 3D printing.

For FDM printing, many brands of PLA, PETG, HIPS, Nylon, and PP have been certified by the FDA as food-safe. Some brands of ABS, ASA, AND PEI have also received this certification, although the number is much smaller. The popularity of PLA as a bioplastic has made it one of the primary materials for food-safe 3D printing, although it also has its limitations.

The resin used for SLA printing is NOT food-safe in any form by default. Uncured resin is highly toxic even for skin contact, making migration of such particles from SLA prints to food very dangerous. However, SLA prints can be used as molds for ceramic parts. In this type of application, the resin can be burned out to create a part that is certifiably food-safe.

Additives

Another element that influences whether a material is food-safe or not is the nature of its additives. Filaments used in 3D printing rarely come in their raw polymer form. Plasticizers are typically added to make filaments less prone to snapping or to improve their mechanical and thermal properties. Dyes are also added to make several color variations of the same polymer.

This means that not all PLA or PETG filaments are food-safe, even if their base polymers should theoretically be safe for food contact. If you’re not sure about the nature of a filament’s additives, then it would be best to stick to those that have been certified or declared complaint with FDA requirements.

3D printing process

Making a 3D printed product food-safe does not stop with the nature of the filament. Along the 3D printing process, the polymer can pick up particles and compounds in trace concentrations that can make it harmful for food contact.

Due to the high temperatures involved in FDM printing, the polymer can be contaminated with particles from the nozzle material or extruder assembly. Care must also be taken to avoid cross-contamination with other filaments, especially if the same 3D printer is being used with ABS, ASA, or other filaments that are typically not food-safe.

Surface finish

Due to the nature of 3D printing, finished products inherently come out with uneven surfaces. When food material goes into these small gaps, crevices, or holes, they can promote bacterial growth. These spaces are also tough to clean. This means that bacterial growth can continue unchecked, eventually contaminating the food.

If post-processing is to be done on a 3D printed object, care must be taken to use a polishing or finishing compound that is also food-safe. The surface coating must be safe for food contact and must also be able to withstand the conditions for the item’s normal use. This may involve contact with high temperatures or cleaning solutions.

As you can tell, ensuring that a 3D printed object is food-safe is going to take a lot of work. Considerations must be made in practically every step of the process.

Will you get in trouble with the FDA?

In the US, the identification and regulation of food-safe items is under the authority of the FDA. This is not something you need to deal with if you’re just 3D printing items for personal use. However, you will need FDA certification if you’re making 3D printed items for selling and widespread distribution.

The good news is that small businesses do not need to go through the same rigorous process of FDA certification as large businesses. The Food Safety Modernization Act (FSMA) of 2015 allows small businesses to sell food and food-contact items as long as they have a Food Safety Plan in place.

A Food Safety Plan should include an identification of possible food safety hazards, a list of preventive controls for such hazards, and a system for the monitoring of compliance with said controls. All of these have to properly documented and available for FDA inspection if necessary. The business must also have a recall plan in case products are found to be non-conforming.

In formulating a Food Safety plan, make sure to always use FDA’s definition of a food-safe product as guidance. This includes using food-safe materials and doing a thorough audit of your 3D printing process to ensure that there is no uptake of dangerous or toxic compounds. You also need to make sure that your business falls under the classification of a “small entity” as defined by the FDA.

Tips on making food-safe 3D printed items

Even if you’re not planning to sell your food-safe 3D printed items, it’s worth the effort to come up with a plan. Using 3D printed food containers or utensils can be downright dangerous if not done correctly, even without the threat of legal liability. To protect yourself and the people close to you, here are some of our tips:

Assign a dedicated 3D printer for food-safe printing

Avoiding cross-contamination is very difficult in 3D printing, especially because the process involves very high temperatures and intimate contact between filaments and 3D printer components. This can be problematic if you intend to 3D print food-safe items in the same printer you used with filaments with toxic ingredients.

It is considered good practice ton use a dedicated 3D printed for your food-safe products. Not only does this avoid cross-contamination, but it also makes it easier to customize a 3D printer with parts that are more appropriate for food-safe printing.

Use a food-safe filament

The most obvious first step in food-safe 3D printing is to use an appropriate filament. Fortunately, there are now lots of filaments that have been certified by the FDA as food-safe. Take note that temperature limitations still apply to food-safe filaments, so you will need to consider the conditions of the intended use. For instance, food-safe PLA still should not be used for containers for very hot fluids.

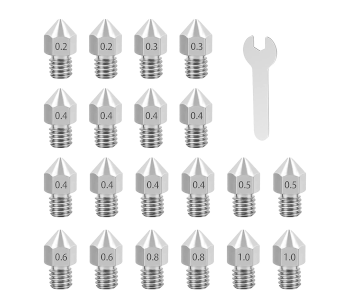

Use a stainless steel nozzle

Most 3D printers come with a stock nozzle made of brass. While brass has the advantage of being inexpensive and having high thermal conductivity, it also contains trace amount of lead. This could leach into the filament as it is extruded through the nozzle. For this reason, it is often recommended to use a stainless steel nozzle instead.

Stainless steel is used in most industrial equipment for food manufacturing. It is durable, corrosion-resistant, and withstands very high temperatures without degradation. The higher strength of stainless steel makes it more resistant to abrasion, thus preventing it from contaminating your 3D printed products.

A compelling reason to upgrade to a stainless steel nozzle is the fact that it is not very expensive. You can buy a 20-pack of these nozzles for less than $10. Take note that hardened steel and stainless steel are different materials – the former may also have trace amounts of undesired compounds.

Switch to an all-metal hot end

In a standard hot end, the filament passes through a short segment of low-friction PTFE tubing before it enters the heating block. While this helps avoid issues related to extrusion, exposure of PTFE to very high temperatures (above 240 C) can result in the material’s thermal breakdown. When this happens, some of the toxic compounds from PTFE tend to contaminate the filament material.

Using a hot end with PTFE tubing is not much of a problem if you’re printing only with PLA or PETG. However, the temperatures needed to melt PC or Nylon can result in gradual breakdown of the PTFE tubing. For this reason, upgrading to all-metal hot end can make your 3D printer more appropriate for making food-safe products.

Keep in mind that upgrading to an all-metal hot end also has its drawbacks. The higher friction in the hot end makes retraction more problematic in the absence of a PTFE tubing. This also makes it a lot harder to print at higher extrusion values.

Heat creep is a phenomenon where the heat from the melting zone travels conductively pas the heat sink. This results in the filament swelling outside the heat block. This can eventually cause extrusion issues. For this reason, optimizing the heat sink is a crucial step in printing with an all-metal hot end.

Use a food-safe lubricant

For the whole 3D printing process to be considered food-safe, every single thing that comes in contact with the filament must also be food-safe. This includes the lubrication in the extruder and feeder gears. This is a detail that many people miss, mostly because the point of contact between the gears and the filament is so small.

Fortunately, food-safe lubricant isn’t exactly hard to come by. They can be quite expensive but you should not need to use much.

Smooth and coat with a food-safe product

We have already mentioned how the uneven surface of 3D printed products can promote bacterial growth, especially after long-term or repeated food contact. This has already been proven by several studies that have shown significant bacterial growth on the surface of untreated 3D printed surfaces.

Smoothing of 3D prints can be done either through mechanical or chemical processes. If you’re printing with food-grade ABS, chemical smoothing with acetone vapor is an option. For PLA or PETG, you’re much better off using sandpaper in several different grit grades.

However, smoothing of a surface is not enough. Even if a surface feels smooth to the touch, it can still be uneven on a microscopic scale. To fill in any of these microscopic gaps, it would be best to apply a coating of food-grade epoxy resin. This also protects the surface of the 3D printed product the effects of moisture. Uncured resin is still toxic even if it is food-grade, so make sure that the coating has been fully cured before use.

As you may have noticed, making your 3D printer products food-safe involves an upgrade in almost every step – from the materials to the 3D printer components. You will also notice that food-safe alternatives of filament or epoxy coatings are more expensive. This simply means your overhead costs are going to increase should you decide to make your 3D printer products food-safe.

Best food-safe filaments

To get you started with food-safe 3D printing, here are some of the more popular filaments that have received certification from the FDA.

1. Filaments.ca Food Safe PLA

The Canadian brands Filaments.ca have cemented their reputations as one of the first few filament brands to receive approval from the FDA. Their official product page highlights the process that they have had to go through for FDA approval. Aside from making sure that the filament and all additives are safe for consumption, they also place an importance on good manufacturing processes, product testing, traceability, and secure storage.

The Food Safe PLA lines of Filaments.ca come in an impressively large range of colors. The polymer, made by InGeo, has been formulated to have a faster crystallization rate, allowing for faster printing. It is also a good candidate for annealing should you need better thermal properties in your finished product.

2. ColorFabb XT and ColorFabb HT

The XT and HT product lines of ColorFabb have been described as being safe for food contact. According to the filament specs, these are free of styrene and Bisphenol A (BPA) – two compounds that are well-known food contaminants.

A distinguishing characteristic of these two filament product lines is that they are based on the Eastman Amphora polymer. This is a high-performance polymer known for high toughness and very high thermal stability.

3. Taulman Nylon 680

Nylon has long been known as a 3D printing polymer with superior mechanical, thermal, and chemical properties. With the Nylon 680 filament, Taulman has taken the material even further by developing a version that is compliant with FDA requirements for food-safe contact. This has come after nearly a year of thorough research and development.

The Nylon 680 filament retains all the desired thermal and mechanical properties of standard Nylon. It can withstand steam sterilization but is not certified for medical use. It only comes in the standard clear, translucent color.

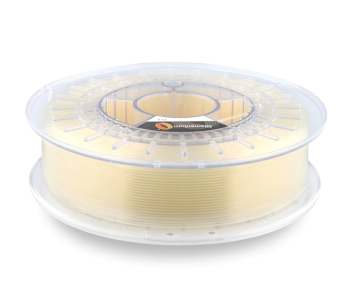

4. Fillamentum ExtraFill

The ExtraFill product line of Czech-based Fillamentum is the brand’s basic line of PLA. What makes this PLA a bit more special is the fact that it has been approved for food contact. In fact, all Fillamentum products have been certified as having concentrations of hazardous substances below the allowed maximum concentration value as set by the European Parliament.

ExtraFill is available in a huge range of pastel and bold colors. They are slightly more expensive compared to standard PLA, but the extra cost is well worth the food-safe characteristics and the line’s color variety.

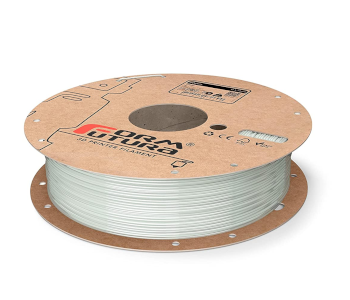

5. FormFutura HDGlass Clear Filament

PET is one of the most common plastics for food containers, so it’s quite disappointing to find that there not many PETG filaments that are considered food-safe. One of the rare exceptions is the Clear PETG filament from the FormFutura HDGlass line.

HDGlass has been certified compliant with FDA requirements for food and drink contact. It retains all of the best benefits of PETG including high thermal stability, low tendency to warp, and odor-free printing. The clear version of PETG is also one of the best filaments you can use if you’re planning to 3D print a project that you want to look as clear or transparent as possible.

Final thoughts

Making food container or other objects meant for contact with food using a 3D printer is a lot more complex than it sounds. There are two elements to be considered for food safety. The first is that the material itself does not cause harmful compounds that can leach onto food after prolonged contact. The second is that the surface of the object does not significantly promote bacterial growth even after washing.

There is a lot of work that will have to go into food-safe 3D printing, even if you’re only doing it for personal use. Keep in mind that food safety is not something to be taken lightly, so every little of effort is crucial.