The Future of 3D Printing – Trends to Expect in 2022

The past two years have proven to be a blessing in disguise for 3D printing. Despite many industries suffering from the effects of the global pandemic, the 3D printing market has shown surprising resiliency and penchant for growth. The fact that 3D printing thrived despite supply chain challenges has highlighted how flexible the technology can be.

Industry insiders are understandably excited about the momentum of 3D printing as we head into the year 2022. Where trends can we expect this year? Will 3D printing continue to grow in mainstream relevance?

Large-format 3D printing

There was no shortage of 3D printing projects in 2021 that focused on using the technology to manufacture products and equipment that were larger than usual. In Australia, a company called AML3D used a technique based on direct energy deposition (DED) to 3D print a “Panama Chock,” a fitting used to guide a mooring line in a shipboard.

In Amsterdam, Dutch robotics company MX3D 3D printed a 12-meter-long bridge out of stainless steel. This monumental task was achieved by using wire arc additive manufacturing techniques performed by six-axis robotic arms. Using 3D printing technology to construct a bridge made the end-product significantly lighter compared to bridges built by traditional methods.

Considering the many industrial large-scale 3D printers being developed today, it is clear that this trend will continue for 2022. This is true for almost all types of 3D printing – whether using metal, plastics, or photopolymer resin. Of the three, large-scale metal 3D printing is perceived to have the potential for the largest commercial growth with an estimated value of $739 million by 2026.

Notable companies banking on this trend include Azul 3D as they develop a 3D printer based on digital light processing (DLP) technology. Using their High Area Rapid Printing (HARP) technique, Azul 3D claims that their 3D printer is 100 times faster and has a 20-fold scale increase over other DLP printers. If Azul 3D can indeed outpace its competitors by a factor of a thousand, it could be a huge step towards making 3D printing more appropriate for mass manufacturing.

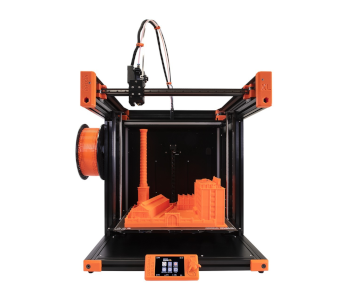

Even in the hobby space, the obsession for large-scale 3D printing seems to have taken root. In 2019, Prusa Research announced that they were developing the Original Prusa XL – an FDM printer using CoreXY architecture with a large 36 x 36 x 36 cm build volume. With a brand like Prusa behind it, many 3D printing enthusiasts were understandably excited.

The Original Prusa XL is open for pre-orders and is priced starting at $1999. We have published a preview of the Prusa XL for those who are considering getting it.

Better interoperability

The huge number of different file formats for 3D models has long been a problem for the design and manufacturing industry. This problem can be traced back to the early years of 3D modeling when every developed modeling software came up with their own unique and proprietary format. Nowadays, this has become a compatibility problem for teams that need to collaborate across different 3D scanning, modeling, and printing platforms.

In 2021, NVIDIA launched the Omniverse. It was billed as a 3D design software that can bridge across different 3D design platforms. At the core of the Omniverse is the use of the Universal Scene Description (USD) format, a file format that Pixar has been using for their animated movies. With the flexibility of Omniverse, NVIDIA says that it can be used for architecture, engineering, manufacturing, art, media, or entertainment.

In more recent news, NVIDIA has announced that they will be releasing a free version of the Omniverse. With this development, the userbase of Omniverse is expected to grow rapidly in the coming months, even considering that almost 100,000 creators are already using the open beta version of the software.

It remains to be seen if this wider adoption of the Omniverse will make the lack of interoperability a thing of the past. It will likely take some time – transitioning from one design platform to another can be a slow process. However, this step to smoother collaboration should make the integration of 3D design and printing easier for large-scale industries.

Sustainability

Since the early years of 3D printing, it has always been described as a more sustainable alternative to traditional manufacturing techniques. In fact, sustainability has been a huge selling point for 3D printing technologies. Compared to subtractive manufacturing, additive manufacturing has the huge advantage of generating much less waste. It also relies on a simpler supply chain, reducing the resources spent on the bulk transportation of supplies.

The 3D printing market continues to evolve to keep up with the market demand for more sustainability. Nowadays, there are filament brands that sell biofilaments or filaments made from sustainable sources such as plant matter. There are also calls to end the use of plastic spools in favor of cardboard spools, or develop a recycling program for the plastic spools.

Even more intriguing is the potential of 3D printing technology to give a second life to used plastics. Technically, any thermoplastic can be broken down into small fragments, melted, and used as raw material for 3D printing.

A company called Closed Loop plastic is already using this concept to turn plastic cups and lids into a 3D printing filament called U-HIPS. The printing performance of the recycled filament is quite good, too, if we are to look at feedback from users.

Creating your own filament from discarded plastic is something that you can also do at home with filament extruder equipment. These are quite expensive, though – the most popular one from Filabot costs close to $2000. There are cheaper alternatives, but these are likely not as heavily used as Filabot.

As the call for more sustainable products becomes louder, we expect the 3D printing industry to respond accordingly. This can come in the form of more sustainable products such as filament made from recycled or Earth-friendly material. Recycling programs for plastic spools and discarded 3D printed products should also become more common. We also expect to see more organizations like The New Raw that are focused on using 3D printing to create art from recycled materials.

Software solutions

The challenges brought about by the recent pandemic has highlighted how 3D printing and additive manufacturing could be the technology of the future. With supply chains hindered all around the world, 3D printing stood out as the manufacturing process that was minimally affected by such issues. According to statistics, 65% of engineering firms around the world have used 3D printing to a greater degree during 2020.

However, the rapid pivot to 3D printing has also highlighted the technology’s limitations. It is an excellent method for churning out parts fast, especially in limited runs, but it is still less practical for mass-scale production. If a company needs to make millions of copies of a design, traditional methods like injection molding or casting still turn out cheaper per piece despite the large initial cost.

To address this shortcoming, the 3D printing industry is looking into software solutions that could better streamline the manufacturing process. Workflow management appears to be the natural next step of evolution 3D printing software that will make the process more adaptable to large-scale industrial manufacturing.

The goal of developing this type of software is to optimize workflows involving 3D printing, thereby making products more economical on a per piece basis. This will make 3D printing more competitive as a manufacturing method for finished parts and not just prototypes. Examples of companies in this space are AMFG, Link 3D, and MakerOS.

Industry experts agree that large-scale manufacturing using 3D printing is still too far off the horizon. The technology will need to evolve a lot to achieve this point, both in terms of hardware and software. However, a renewed focus on software development is a step in the right direction towards reaching this ultimate goal.

Final thoughts

Considering how the world has seemingly turned upside-down in the last two years, it is exciting to see how 3D printing has continued to thrive. It has also gained the attention of many manufacturers who now see the unique benefits of the technology.

3D printing is headed into 2022 with a lot of momentum. More people are talking about it, both as a hobby and as an alternative for manufacturing. Considering the level of interest and the industry needs, the expect the topics we have listed above to be the focus of this year’s 3D printing news. We shall all see how this pans out – we would love to be pleasantly surprised with unexpected developments.