3D Printing with Gold Filament: Properties and How to Use

With its characteristic color and luster, gold has always been a highly valued metal throughout almost the entire human history. Often used in jewelry, the ability to work with gold and create customized pieces remains a valuable and exclusive skillset. Those with 3D printers may ask – would it be possible to use 3D printing technology to come up with custom projects that made of gold or simulate the appearance of gold?

The answer to both those questions is yet. As you would expect, budget comes into play. What are your options if you want to 3D print your very own custom gold jewelry?

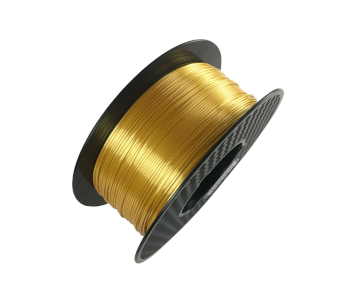

Option 1: Silk Gold PLA Filament

This Silk Gold PLA Filament from CC3D is one of the more popular options for those who want to try their hand at 3D printing something that looks like gold. The mean reason for the popularity of this filament is the fact that it’s very cheap. That’s just another way of saying that the filament does not contain any real gold.

This filament uses gold-colored silk strands embedded in a PLA matrix. The use of silk is an amazing idea which makes the material reflective enough to simulate the luster of real gold. Prints made with this filament naturally come out shiny and glossy, although a bit of sanding and buffing doesn’t hurt to get rid of the layer lines.

Aside from the low cost of the filament, another advantage of using silk instead of metal particles is that the filament isn’t exceptionally abrasive. Using the stock brass nozzle of most 3D printers with solid-infused filaments is always problematic as the solid particles tend to wear down the brass materials pretty quickly. This isn’t an issue with silk strands.

The Silk Gold PLA filament prints at usual PLA printing temperatures – anywhere within the range of 195 to 230 °C. As with normal PLA, a heated bed isn’t a strict requirement when working with Silk Gold PLA, although a bed heated to around 60 °C is still ideal. Silk Gold PLA is a relatively easy and beginner-friendly filament that delivers visually pleasing results.

Since the filament doesn’t contain any solid particles, you will miss out on the characteristic heft of 3D printed projects made from solid-infused filament. This heft lends a certain level of premium quality to 3D prints. A print made with Silk Gold PLA looks good, but you’re not about to fool anyone that it’s made with real gold.

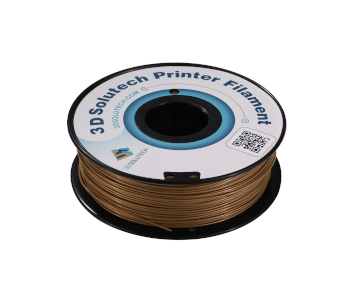

Option 2: 3D SoluTech Real Gold PLA Filament

This Real Gold filament from 3D SoluTech is another viable and low-cost option if you want your prints to have a touch of elegance. Despite the “Real Gold” slant of the filament’s marketing, nothing could be further from the truth. This is standard colored PLA with no solid particles, which is both a good and a bad thing.

The lack of any metallic particles in this Real Gold filament means that printing it isn’t any more complex than printing with standard PLA. You can print at low temperatures and without a heated bed without worrying about layer adhesion or warping problems. You can also safely use a stock nozzle with no worries about it getting worn down.

Since just about anyone who has tried 3D printing knows how to work with PLA, then this could very well be the easiest way to get some gold into your 3D prints.

In this case, however, quality takes a backseat to ease of use. The prints made with the Real Gold filament look closer to brownish bronze than gold. The closest metallic counterpart to the finish of the Real Gold filament would be copper. Since it doesn’t contain any naturally lustrous materials, getting your finished print to “shine” will involve the whole spectrum of finishing techniques from sanding and buffing to priming.

Despite its imperfections, the SoluTech Real Gold filament is still a compelling choice for hobbyist 3D printers who want to exercise a bit of creativity but don’t want to handle a complex filament material. The filament still looks great and “pops out” in the proper setting. It’s an inexpensive filament that’s easy to work with and requires no modification of your stock 3D printer. Just managed your expectations as there’s no way that it resembles “real gold.”

Option 3: GizmoDorks Gold ABS Filament

Famous 3D filament brand GizmoDorks puts a spin on their gold filament by basing it off of ABS instead of PLA. This should be a good choice for those who want their gold prints to have an extra factor of durability and thermal resistance. Naturally, the GizmoDorks gold filament comes with the usual complications of printing with ABS.

Like SoluTech’s gold filament, the gold filament of GizmoDorks contains no solid particles but is merely colored ABS. This simplifies the whole technique of 3D printing this gold filament, especially if you’re already comfortable with working with ABS. Compared to PLA, an ABS print is a bit more stable in terms of chemical and thermal resistance. It’s also rugged enough for limited functional use, although we imagine you’ll be using this filament to create display items.

The finish of this gold filament is also somewhat dull but is closer to a yellowish butterscotch color than bronze. The bright finish looks great even without any finishing. However, this filament presents the perfect opportunity to practice the ABS finishing technique using an acetone vapor bath. This technique melts a very thin layer of plastic material on the ABS print, giving it a perfectly smooth and shiny surface.

If you’ve worked with ABS before, then you probably know that printing with it isn’t exactly easy. The high printing temperature needed for ABS combined with its thermal contraction index makes it particularly prone to warping. Hitting the perfect combination of bed temperature, print speed, and nozzle temperature is going to take a bit of work. The consistency and quality of this filament from GizmoDorks is pretty good, so that should help you perfect your technique eventually.

Is there technology for 3D printing with real gold?

One thing that’s common with all the options above is that none of them use real gold. Unlike other metals such as brass or copper, gold is very expensive even in small amounts. A 1-kilogram spool of filament infused with real gold would probably cost tens of thousands of dollars, which isn’t a great fit for a process that requires repeated cycles of trial and error.

There is a way for 3D models to be turned into solid gold objects, but they rely on different 3D printing technologies. The most commonly used are direct metal laser sintering (DMLS) and lost wax casting. Sintering is done by using a laser to solidify a powder raw material, similar to the process of selective laser sintering (SLS).

Lost wax casting is a more indirect way of using 3D printing to work with gold. Instead of printing with gold, this technique starts by using a 3D printer to create a wax model. A mold is made from the model, usually by enveloping it with plaster. When the mold has solidified, it is punctured in the bottom and exposed to high temperatures to allow the wax to drain out. The mold is then filled with liquid metal – in this case, a gold alloy.

Unfortunately, neither of these techniques can be done at home. A DMLS machine can cost up to $150,000, and homes aren’t exactly equipped for working with molten metal. Consider how valuable gold is and how technically demanding and expensive the equipment is, it’s best to leave this kind of job to the experts. Gold 3D printing services are offered by professional 3D printing companies like i.materialise and Cookson Gold.

Final thoughts

3D printing with gold would be a dream come true for a lot of makers of jewelry and ornaments. The sheer versatility of 3D printing combined with the value and workability of gold would open a lot of avenues for more inventive uses of one of the most precious metals in human history.

However, 3D printing technology isn’t quite there yet. You can come up with faux gold 3D printer projects using filaments that simulate the appearance of gold but working with actual gold will rely on more traditional methods. 3D printing is still useful in the art of crafting with gold but in more indirect ways, such as in the production of a wax model for lost wax casting.