Your Guide to Buying a 3D Printer – How to Make a Better Informed Decision

3D printing technology and 3D printers are no longer the sole tools of scientist and engineering projects. As demand grows, the technology improves and prices continue to fall. It’s the same with all new technology, only 3D printing and printers are not all that new. In fact, it’s been over 30 years since that first model came into existence. Back then they called the entire solid imaging process stereolithography, but we’ll stick to 3D printing. It is new, though, for home users, schools, and libraries, etc. That’s because it’s become a lot more affordable in recent times. Okay, so 3D printing is still not ‘cheap’ per se, but it’s a lot cheaper than it used to be. Although you don’t need to own a 3D printer to be able to print in 3D, more people than ever before are investing in their own machines.

It’s the purpose of this guide to make the buying process as easy as possible. It will help you make a better informed decision before you part with your hard earned cash. Whether you’re in the market for a 3D printer now, or at some time in the future, this guide is for you.

What You Will Learn

In this guide you will learn that not all 3D printers are equal, not in cost, quality, functionality, or materials. Keep reading to find out what kind of 3D printer meets your needs, your budget, and why. The highest price doesn’t always mean you’ll get the best model either. This all depends on what you plan to build with the printer and your expectations. You will have all sorts of questions, and it’s the aim of this guide to answer them for you in detail.

Below are the frequently asked questions by those new to 3D printing. We’ve divided them into two categories, general, and technical. The more general FAQs include:

- Do you really need a 3D printer?

- What kind of printer should you consider?

- Which printer’s capabilities meet your expectations?

- What are your ultimate goals?

- Where’s the best place to buy your 3D printer?

Technical FAQs covered include:

- How important is the 3D print speed?

- What type of materials should you print with?

- What size print bed should you go for?

If you’re new to the world of 3D printers and printing technologies, you may want to view our glossary of terms at the back of this guide. To keep things simple, we’ve only included words and terminology used in this guide. You can view the glossary of terms here.

Beware of Buying on Impulse

All too often people go out and buy something on appearance, price, a friend’s recommendation, or all three. This common impulse applies to all kinds of things, not only 3D printers. How many times in your life have you bought something and later regretted it? Perhaps it didn’t do what you had hoped it would. Or, as you got more knowledgeable about the item, you wished you’d spent the extra and gone for something that was more durable and capable. A good, low-tech, example might be with a quality pair of shoes. Let’s say you bought a cheap pair that looked fine on first inspection, and cost very little. You later discover that the quality shoes—though twice as expensive—would have lasted five times longer, and were more comfortable and supportive to your feet. You get the idea. The point is that it pays to do a little research prior to purchase.

Never forget, a salesperson, or the sales department of a product, wants to sell you their equipment above all else. It’s why they tend to exaggerate or at least highlight only the good points of what it is they’re trying to promote. A little time and research into a product, including 3D printers, is well worth the effort. Consumer reviews with star ratings can also help to make a better informed decision.

Checking all the Boxes

The way to shop for 3D printers is by knowledge first followed by a box checking exercise. Once you know your budget, expectations, etc., it’s then just a simple case of checking your boxes as you work down the list. If you can’t check them all, you’ll at least want most of the items on your list covered.

As you can see from the FAQs above, we’re going to cover all the essential points on buying a 3D printer. For now, take a quick look at the table below. Fill in your answers as best you can before reading the rest of this guide. Don’t worry if you’ can’t answer all the questions yet. You can return here and add to, or delete from, this table at will. By the time you’ve read through this guide you’ll be able to complete the right side column with confidence.

WHAT DO YOU WANT FROM A 3D PRINTER?

| Q. What do you want to print exactly? | |

| Q. What size do you want to 3D print your objects? | |

| Q. What type of print materials do you want to use? | |

| Q. What print resolution do you expect to print at? | |

| Q. Do you want to print with more than one color? | |

| Q. What surface should you build on? | |

| Q. Should you opt for a closed or open frame? | |

| Q. What are the limitations of this printer based on your personal requirements? |

Again, don’t worry if you can’t answer all the questions just yet. Everything will start to make a lot more sense as you read through our no-nonsense guide.

Q. Do you really need a 3D printer?

It’s a simple question, but your answer might not be so obvious. Let’s say you have something you want to print in 3D, and you’ve even got your design model in place. Have you really thought about where you go after that? Have you got any other projects in the pipeline? And if yes, have you checked to see if your new 3D printer is capable of printing those too? See, you don’t have to own a 3D printer to print in 3D. And if you’ve only got one or two projects lined up, you need to ask yourself about the role of the printer after you’ve completed those jobs. In some cases, it makes far more sense to just get someone or some 3D printing services to produce your 3D models for you.

Ask yourself how much you know about 3D printing and the current technologies. If TV tech shows, YouTube videos, and sales pages have impressed you, is it enough? You’ll be able to make much better decisions once you understand what you’re getting into—it’s as simple as that. There are plenty of great online tutorials if you still have some to learn. Don’t forget, you can continue to design your 3D models for free, and then use a 3D printing service to build the parts for you. A couple of good examples are Sculpteo and, 3D Hubs, but there are others. This is a great way to learn about 3D technology, materials, and the available 3D printers before making a purchase.

Q. What kind of 3D printer should you consider?

You need a printer that can produce what you want, and at the quality you expect. You also need a machine that has the potential to print the things you hope to make in the future. At the time of writing, there are nine 3D printing technologies in use. Obviously these are not all considerations for home users, that’s unless you plan to print complex parts in metal and other special materials.

The nine major printing technologies are:

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Fused deposition modeling (FDM)

- Selective Laser Sintering (SLS)

- Selective laser melting (SLM)

- Electronic Beam Melting (EBM)

- Laminated object manufacturing (LOM)

- Material Jetting (MJ)

- Binder Jetting (BJ)

For home users, the two most popular and affordable options are Fused Deposition Modeling (FDM) and Stereolithography (SLA). These are the one’s we’ll focus on in this guide.

Fused Deposition Modeling (FDM)

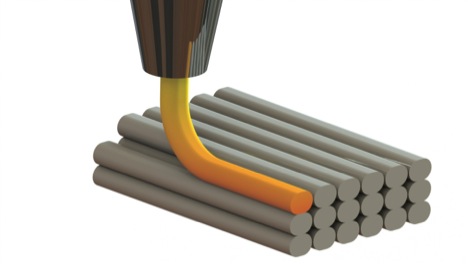

Out of the two, FDM is by far the most common for 3D desktop printing. A US inventor named Scott Crump first developed FDM technology in the late 1980s. Crump is also the co-founder and chairman of Stratasys, one of the leading manufacturers of modern 3D printers. Since those first FDM machines, there have been other organizations that have adopted similar technologies to FDM, using various other names.

FDM printers are the least expensive machines for hobbyists and enthusiasts. They’re also the most easy to come by. They operate by first heating and then extruding a thermoplastic filament to create the part—one precise layer at a time. After each print cycle, the print table, AKA the print bed or build plate, lowers the object slightly to allow for the next layer to go on top. The printer repeats this process until the object reaches its finished height. Objects which have overhangs require support structures or materials to fortify the build process. It’s somewhat more complex than that, but this is the bare basics of how the technology works.

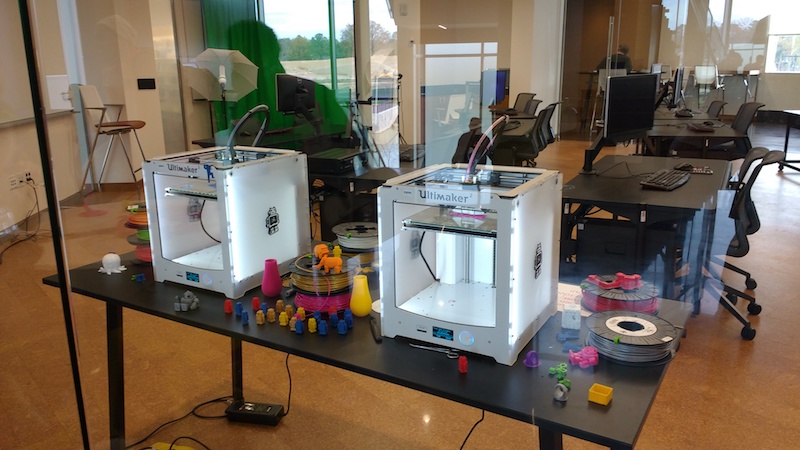

From a buyer’s perspective, the choices can be overwhelming at first sight. After all, there are over 50 companies offering 3D printers using FDM technology. The prices can range from just a few hundred dollars to several thousand. This is why it pays to read through our guide, so that you can narrow down your choices. You will then be in a position to zoom in on only those models that match your budget and realistic expectations. Filament rolls (the print material) is reasonably inexpensive too, ranging from as little as $25 per kilo. This technology is forever evolving, and that means newer, more improved models will continue to appear periodically.

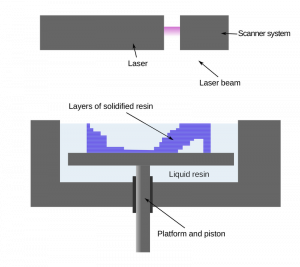

Stereolithography (SLA)

SLA 3D printers are another great choice for home users, though they work in a different way. SLA is a particularly versatile technology. It creates 3D parts by exposing layers of photosensitive resins to an ultraviolet laser beam. In laymen’s terms, that means the process begins with liquid plastic. It then cools down to a solid form which eventually produces the hardened 3D objects. Like FDM printing, the printer moves down by the exact thickness of a layer after each print cycle. Each new layer goes on top of the previous, hardened layer, until model completion. Like FDM, SLA 3D printing also requires support structures when printing objects with overhang. The end product needs rinsing, and sometimes baked in a UV oven to complete the process.

FDM Vs SLA: The choice between the two is quite straightforward. It all comes down to costs and quality. For high precision and an ultra-smooth finish, use an SLA printer if price is not an issue. If you’re on a tighter budget, then you will want to look at your best options available in FDM printers.

Q. Which printer(s) meet your expectations?

This is a simple question, but if you overlook it you could be throwing money away and end up disappointed. Remember, not all 3D printers are equal. This applies to machines as well as technologies. Imagine getting a 3D printer home only to find out that it’s too small for your needs, or that the quality is substandard. The cost doesn’t stop at the device either, there are materials and support structures/materials to consider also.

Most novices will not be expecting to print large objects with intricate details, but some of you will. And if you want to sell your services to other people, then high quality objects will more than likely be a priority. In this case, you will want to focus on two very important factors:

- Print resolution: the smaller this is the better

- Print speed: typically includes 40-50mm/s, 80-100mm/s, and 150mm/s (see below)

There are so many great 3D printers for sale these days. The thing to be careful of is the price. In the budget range, there might not be all that much difference between a $350 model and one that costs $600. Think carefully about what you intend to print and the quality you expect. A higher priced device doesn’t always translate to higher quality, at least not to the human eye. This is why you need to know what you want to print—specifically—and your expectations.

Q. How important is the print speed?

You might think that faster is better, but it all depends what you expect from the end piece. It’s important to note that the faster a 3D printer prints, the lower the output quality will be. It’s a good reason not to let print speeds impress you too much at the buying stage. This is particularly the case with printers that boast more than 150mm/s. Once you know the type of parts you plan to print, then you can determine the best print speeds for your needs. Slower is always going to be the better option, at least for larger, high quality objects.

3D printing is not a hobby or an occupation for the impatient. Once it’s set up and running, just let it be. In other words, leave the room and come back later—much later with some projects. To ask the question: how long does it take to print in 3D, is akin to asking how long a piece of string is. It takes as long as it takes. The size and the complexity of your object play a major role in print speed. The layer height you choose is another. If you print at a higher resolution, you can expect to wait longer, but your reward is a better quality, much smoother object. As you can see, it’s impossible to give an average time, which could be anything from a few minutes to several hours, depending on the above.

Q. What are your ultimate goals?

If you’re certain you want to invest in a 3D printer, pause for thought first. Think about your ultimate goals carefully before making a decision to buy anything. You wouldn’t buy a tiny two-seater sports car if you just got married and planned to start a family right away. Likewise, you don’t want to invest a small, budget 3D desktop printer if you have bigger ambitions planned. It would mean your first printer soon becomes surplus to your requirements, and therefore a waste of money—in hindsight. So your question is this: do you expect to design and print bigger and better things as soon as you gain more experience? And will you want to experiment with other materials, and print multiple colored objects?

Point to note: Not all printers can print using different colors. For multi-colored printed projects, you will need to look for 3D machines that have multiple extruders.

Q. Where’s the best place to buy a 3D printer?

Our Buyer’s Guide is the best place for information. We have listed the best 3D printers you can buy.

You can find 3D printers in all the usual places online like Amazon, eBay and many others. If money’s tight, a secondhand option might be the way to go. The secondhand route, though, is more risky, not least because you have no idea how much use the machine has had. For first time buyers, it’s better to buy new, from the high street. At least this way you can see, touch and test the machines before committing. The most important thing is that you can take it back to the shop if there are any problems. Sending big objects through the post, on the other hand, can be time consuming, frustrating, and unpredictable.

The best advice is to make a shortlist of printers you’re interested in, and then read up about them online. You can find plenty of reviews and YouTube vids on most popular models, and also user experiences. Once you become familiar with the models and prices on your shortlist, it’s time to shop. Ideally, you will want to see live demos and get to speak to people who understand the industry inside out. Remember to always have your 3D printer checklist with you too. This is in case you come across models of interest that you’re not familiar with.

Q. What type of materials should you print with?

3D printing technologies have come a long way since the early days. Not only are the machines better, but also the types and ranges of materials used. So what type of materials should you print with? That all depends on what it is you’re printing and your end goal. Not all 3D printers can print with all kinds of materials. Most of you reading here will have no interest in the industrial-type printers. Your focus is likely to be with consumer-oriented devices, AKA desktop 3D printers. These types of printer typically use a plastic filament (see below). You can find them all online, in a range of diameters, lengths and colors. Here we look at the popular ABS, PVA, and PLA materials.

Acrylonitrile Butadiene Styrene (ABS): This is a great material for kitchen appliances, musical instruments, and toys, etc. Lego bricks are a great example of ABS.

Polyvinyl Alcohol (PVA): This is a special type of water-soluble plastic. We can find it in paper adhesive, in various types of packaging, hygiene products, and in kid’s putty. Fishing bait containers use PVA too, that dissolves under water, thus releasing the bait to attract nearby fish. In 3D printing, PVA sometimes acts to provide support structures to 3D objects during the build process.

Polylactic Acid (PLA): Compared to ABS or PVA, PLA is an environmentally friendly material that’s beneficial for a wide range of uses. You can find PLA in anything from surgical implants to food packaging, disposable garments (including diapers), and lots of other creative ideas.

The Importance of Filament Diameter

Each of these materials has their pros and cons. What type you opt for will depend on your 3D printed model. Once you know what you intend to print, then you can explore the best material for the job. Before you even order your material, you first need to check your printer to see what the filament diameter is. You could have a printer that accepts both sizes, 1.75mm or 3mm. Most models don’t accept both sizes, so be sure to check before ordering. Finding these materials is easy, especially online. You usually buy filament by weight, with options of spools in 750gm, 1kg or 2.5kg.

Q. What size print bed should you opt for?

3D print beds come in both heated and non-heated options. The bed is crucial to the outcome of your 3D printed part as it’s what holds the object steady from the outset. To still the object during the build, you have to adhere it to the 3D printer bed before the process begins. There are two ways to do this, either by using glues or by preheating the bed. If you use ABS filament, a heated bed is necessary. PLA filament is more flexible though, and you can use either heat or an adhesive. A bigger 3D print bed also means you get to print bigger things.

Q. Should you choose an open or closed frame?

Finally there’s that question of open frame vs. closed frame. Both types have their plusses and minuses, so let’s take a look at these now.

An open-frame 3D printer is, as the name suggests, more exposed. This can be convenient because it gives the user easy visibility of an active job. It also allows quick access to the printer bed and the extruder. On the face of it, this seems like the most convenient setup, but there are a few downsides to consider. Let’s look at why a closed-frame arrangement is a better option for some.

Closed-frame 3D printers come with a fully enclosed structure. That means it has a door, walls, and a lid of some description. The first thing to note about closed-frame printers is that they’re safer—period. The safety aspect is certainly worth considering if you have kids around the house, or pets. You don’t want them to accidently burn themselves by touching the exposed extruder. Closed-frame printers also help to reduce odors, which you’ll be thankful for if printing with ABS. After a while, the burning plastic smell can become overwhelming, especially in a room with poor ventilation. Another plus point for closed-frame 3D printers is that they tend to be quieter. Any reduction in printing noise is welcome if you’re working in the same room as long print job. Finally, closed-frame 3D printers can often maintain temparatures more smoothly.

Decision Time

There are all kinds of things to consider before buying a 3D printer, particularly if it’s your first one. If you’ve read through this guide from top to bottom, you should now have a good basic idea of what to look for. All you have to do now is prepare a shortlist of printers that match your needs and expectations and decide between them.

Quick Glossary of 3D Printer and Printing Terms

Build Plate, AKA Print Table and Print Bed

This is the surface where the 3D printer forms the 3D part

Build Platform

The part of a 3D printer that supports the build plate above

Extruder

This is the part of a 3D printer that melts and then layers the melted thermoplastic material

Filament

The special plastic material that the printer melts and extrudes through the 3D printer nozzle

Filament Diameter

There are two diameters used for 3D plastic filaments. One is 1.75mm and the other 3mm. Some printers can use both, but most will only use one, so check before you buy your filament.

Layer Height

The exact thickness of single layer in a 3D printed part

Nozzle

The part of the printer that controls the amount of extruded material

Overhang

Any part of a 3D object that lacks support underneath, e.g., a part that juts out 45 degrees or more

Resolution

Minimum detail and layer thickness measured in dots per inch (dpi)

Supports (materials or structures)

Support materials or physical structures are there to support 3D parts during the build process. Their primary role is to support gaps between the model and large overhangs. The user removes all support materials or structures at the end of a successful print.

Printer Types

- FDM – Fused Deposition Modeling: Perhaps the most common type of 3D printing. FDM heats and melts the special plastic filaments to print 3D parts

- SLA – Stereolithography: This is now one of the oldest forms of 3D printing, and also the most reliable. SLA uses liquid plastics to create objects.

- SLS – Selective Laser Sintering. This technology relies on a special laser that converts (sinters) special powdered material into a solid form

- SLM – Selective Laser Melting: A high-powered laser melts powdered metal material to build solid objects. This metal material quickly solidifies during the 3D printing process

- EBM – Electron Beam Melting: This is one of the newer technologies. The EBM method uses a powerful electron beam to heat and melt powdered metal.

- LOM – Laminated Object Manufacturing: LOM is one of the fastest 3D printing technologies. It’s typically used to 3D print objects using sheets of layered plastic and paper build materials.

- MJ – Material Jetting: This technology uses inkjet print heads to melt wax type materials onto the printer’s build platform.

- BJ – Binder Jetting: This 3D printing process is a high-tech, affordable solution for building complex, fully-functional metal parts. It bonds a liquid binding agent onto thin layers of a special powder thus ‘binding’ the particles together to create 3D printed models.

Visit this page for a full list of 3D printing materials.