Has 3D Printing Changed the World?

It’s probably already been a decade since tech experts around the world flouted the idea of 3D printing being this revolutionary, world-changing technology. Back then, 3D printing was this exciting new technology that few people know of, much more saw in action themselves.

Several years down the line, has 3D printing fulfilled this potential we have heard long ago? In what industries has 3D printing proved to be revolutionary? In this article, we’re focusing on all the ways that 3D printing lived to the hype and the other promises that the technology is yet to fulfill.

3D printing – from then until now

The early beginnings of 3D printing as we know it today can be traced back to the 1970s. Back then, 3D printing was nothing more than a concept. It was only in the 1980s when patents for the first 3D printers were filed and the first actual models were developed. At the time, owning a 3D printer would have cost you upwards of $300,000.

Through the decades, 3D printing technology diversified across methods that used thermoplastic extrusion, selective laser sintering, and powder jetting. One of the earliest commercially available 3D printers was sold in 1992 by Stratasys, a company that remains one of the most prominent in today’s market.

By the 2000s, 3D printing had taken on a new moniker – additive manufacturing. This puts it in direct contrast with more old-fashioned subtractive manufacturing, which involved cutting away from a single solid block of material. Additive manufacturing was often described as a more flexible manufacturing method that resulted in less waste.

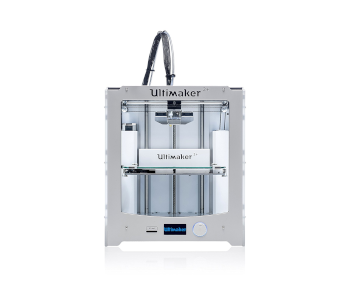

Modern 3D printing technology is not a huge departure from the technology that was developed a few decades ago. They still relied on one of three methods – extrusion of hot plastic, sintering of powder, or jetting of binder agent onto powders or gains or raw material. The major difference is that modern 3D printers are now simultaneously more affordable and more sophisticated.

The increased accessibility of 3D printers has been a great contributing factor to its present popularity. With 3D printers that cost less than $300, there is now a thriving global community of casual 3D printing hobbyists. On the other end of the price spectrum, high-end 3D printers have found their way into industries and commercial firms.

3D printing in medicine

In terms of social relevance, there is probably no greater contribution that 3D printing has done than what it has provided for the medical community. 3D printing has been used in medicine in several ways – to provide structure for organ growth, as an alternative means for drug delivery, and for creating the next generation of prosthetics.

Prosthetics and implants

For years, 3D printing has already been an instrumental technology for creating prosthetics. Unlike older technologies, 3D printing was cheap. This made 3D printed prosthetics perfect for kids who had to get new prosthetics as they grew. Based on frontier projects by a company called Limbitless Solutions, 3D printed prosthetics cost about 90% less than those made using older and more traditional methods.

3D printing has also become a way to inject personality into prosthetics. Brightly colored prosthetics bring cheer to people with disabilities, especially to kids.

Orthopedic implants have also been a fairly common application of 3D printing in the last couple of years. The design freedom of 3D printing has been most valuable in this field. Parts with complex geometries, such a knee replacement or implants with porous structures, can be easily made via 3D printing.

Bioprinting

Organogenesis is an exciting field for 3D printing. This refers to the use of cells to replicate human organs, allowing for organ transplants without the need for a donor. In the early days, 3D printing was used in this field to provide the structure on which organ cells anchor. This is a process called biomimicry.

The more recent field of bioprinting uses a technology patterned after 3D printing to deposit biomaterials and print tissues and organs. This is a lot faster and more controllable than waiting for cells to replicate.

Bioprinting has already been used to successfully reconstruct tissue for various parts of the human body. However, 3D printing an entire functioning organ remains an elusive goal. Despite the precision of 3D printing technology, it still cannot infuse organs with working blood vessels and other nutrient delivery systems.

Research in this field is ongoing. In 2019, researchers in Tel Aviv in Israel succeeded in 3D printing the first-ever semi-functioning heart. Printed using a hydrogel, the heart included essentials components such as vessels, collagen, and distinct chambers. The heart, although rodent-sized, had pumping ability.

Personalized medicine

Several pharmaceutical companies around the world have been exploring personalized pills made using 3D printing. The idea is to create multi-drug pills that make drug administration easier and more convenient to patients. This same technology can also be used to create patient-specific dosages or to create a mechanism for controlled drug release.

In 2015, the FDA approved the first-ever 3D printed drug – the SPRITAM levetiracetam for the treatment of seizes in adults and children with epilepsy. This drug, developed by Aprecia Pharmaceuticals Company, uses 3D printing to create a highly porous structure that disintegrates rapidly with liquid. With this technology, a high drug load (up to 1000 mg) can be administered rapidly via oral means.

Space exploration with a side of 3D printers

3D printing has played a prominent role in space exploration, mostly through NASA’s Made in Space program. The objective of this program was to give space stations the capability to 3D print essential tools and parts instead of bringing them from the Earth. This made space trips a lot cheaper and addressed the issue of excessive supplies being stuck in space stations.

In 2014, a ratchet wrench became the first 3D printed tool in space. Even better, the model for the wrench was transmitted all the way from the Earth to the space station. The wrench was made using the Additive Manufacturing Facility which uses FDM technology specially designed to work on a zero-gravity environment.

The next stage of development for 3D printing in space is focused on the use of metal powders as raw material. This will address the need for metal parts and tools in space stations. However, there are a lot of technical hurdles before this goal can be realized. Metal powder can be hazardous in zero gravity and requires a large power source to sinter together.

Ultimately, the goal of 3D printing technology for space exploration is to create habitats on Mars or on the Moon. The idea is to use materials native to the destination to create structures appropriate for human shelter. In 2015, NASA launched the 3D Printed Habitat Challenge to explore this concept. However, we’re probably at least a decade away from this being a reality.

3D printers for household and casual use

Let’s scale back the discussion and look at 3D printers used in households and small workshops. This has probably been the biggest paradigm shift in the 3D printing industry in the last decade. Instead of large-scale 3D printers used in industrial settings, desktop 3D printers quickly became the means with which most people became familiar with 3D printing.

Transforming the spare parts industry

There is certainly some argument for the practicality of having a 3D printer at home. If you have a 3D printer at home, you never have to worry about how to replace that broken bracket in your washing machine or that loose swivel in your office chair. 3D printers are also valuable for those who like doing DIY projects at home.

The spare parts industry has recognized the value of 3D printing as a more efficient means of after-sales service delivery. Instead of producing spare parts at a mass scale, these parts can be manufactured on demand. By maintaining a “digital inventory,” brands can offer spare parts without having to spend on large-scale manufacturing and logistics expenses.

Hobby communities

Right now, there are likely thousands of active online communities of 3D printing hobbyists and professionals. These communities have made it a lot easier for beginners to get into the hobby, with seasoned users eager to provide advice.

Sites like Thingiverse and CGTrader host free 3D models that users can download for free. If you own a 3D printer, you will literally never run out of ready-made 3D models to print.

Small businesses

Many casual 3D printing users have sensibly extended this hobby into small businesses. These commercial services can range from custom jewelry to architectural models and product prototypes. This has also emphasized how modern 3D printers have made the technology a lot easier to learn.

The video game, popular culture, and science fiction communities have proved to be a huge market for 3D printing services. There is certainly an appeal to being able to design and create your own figurines of your favorite movie, comic, or video game characters.

3D printing against the pandemic

The global COVID-19 pandemic has caused chaos in just about every sector of society. However, it also provided opportunities for creative or innovative solutions. The 3D printing community stepped up in a big way to respond to the pandemic, especially in creating personalized PPE parts and other spare parts for medical equipment.

The pandemic has caused an unprecedented surge in the demand for PPEs and medical equipment. What made the problem worse was how supply chains were disrupted worldwide because of people not being able to move around. Fortunately, local 3D printing communities filled in this supply chain gap.

In the past several months, 3D printers all around the world have been hard at work creating ventilator valves, face shields, filters for respirators, mask fitters, or even emergency dwellings for those who need to be quarantined.

This pandemic has truly highlighted how 3D printing can be a disruptive force in the manufacturing industry. It was an effective tool when users collaborated. When a hospital in Brescia needed valves for intensive care devices, a company called Issinnova brought a 3D printer to the hospital and produced the missing piece.

In a few days, a digital model of the Venturi valve needed for intensive care was made available online for free. With the model freely available, 3D printers around the world were able to help the logistical needs of nearby hospitals and medical care facilities. This became the strength of 3D printing – it relied on a distribution network that defied traditional physical and logistical limitations.

The unfulfilled promise

Despite everything that 3D printing has achieved so far, there are still a few areas where the technology continues to struggle. For years, there have been many attempts to create a 3D-printed home. A proof of concept was demonstrated by the Ynhova Project in France when they built a fully functional house in just 54 hours. According to the project owners, the 3D printed house costs 20% less than a traditional house.

Reduced costs and shorter turnaround times may be the appealing aspects of 3D printing a house. However, they are still considered to be less durable than those made using traditional construction methods. In fact, the issues of 3D printed houses are the same ones that have hindered the more widespread use of panelized construction.

Most 3D printing that is being done today has been done using plastics. This serves the hobby market well but provides limited utility for industrial and commercial applications. Although there is now a wide range of thermoplastics and resins that are compatible with 3D printing technologies, there is still a gap in the market for 3D printing with metals.

The technology for 3D printing metals is already available but is still very expensive for widespread use. This is an area that several companies are focusing on, including Desktop Metal. Developing more affordable metal 3D printers is one of the major goals for the industry for the year 2021. If metal 3D printing becomes more common, it will surely usher in another new era in product prototyping and manufacturing.

Final thoughts

In several ways, we can affirm that 3D printing has had a significant effect on the world. It has created a shift in paradigm in the manufacturing industry, as parts no longer need to be produced in mass and delivered through traditional means. This has been demonstrated in the past few months as the world became ravaged by a pandemic.

However, 3D printing still has a lot of unfulfilled promises. Certain applications, such as in construction, have not moved past the proof-of-concept stage. Even if 3D printed houses never pan out as a practical solution, we think that it’s safe to say that 3D printing has proven to be a force for good. Only time will tell if it’s going to as world-changing as it was hyped to be.

Great article!

3D printing, the process of making three-dimensional objects from a digital file is as exciting as it sounds. There are many benefits of 3D printing that are affecting the world in a positive way.

1. cutting costs

2. faster than buying or ordering

3. customizable

4. sustainable solution

5. creating unusual, unseen objects.

All these could be commonly applied in any field and it could prove helpful.