Dissolvable HIPS Filament Properties and Best Brands

In the field of filaments used in 3D printing, there is no doubt that ABS and PLA are way ahead of the pack in terms of popularity. However, there are a couple more options available out there – perhaps not as widely used, but nevertheless useful. One of these is the HIPS filament

The basics

HIPS stands for High Impact Polystyrene. It is a graft copolymer that combines polystyrene and polybutadiene. The result is an inexpensive plastic that combines the best of both worlds: the rigidity and toughness of polystyrene, and the flexibility and impact absorption of polybutadiene. The resulting polymer has a resilience that standard polystyrene does not have. It is stronger without being brittle, and is more capable of taking stronger impacts without breaking, thus the “high impact” qualifier in its name.

What is HIPS used for?

By itself, HIPS is an inexpensive and easy to fabricate plastic that has excellent impact resistance and machinability. It is a readily moldable material with excellent dimension stability, and is easy to paint and glue. Outside of 3D printing, HIPS is used for the production of food containers as natural HIPS has been declared FDA-compliant for food processing applications. You have probably seen HIPS used for cups for hot and cold drinks, refrigerator linings, computer housings, automotive instrument panels, toys, and TV parts.

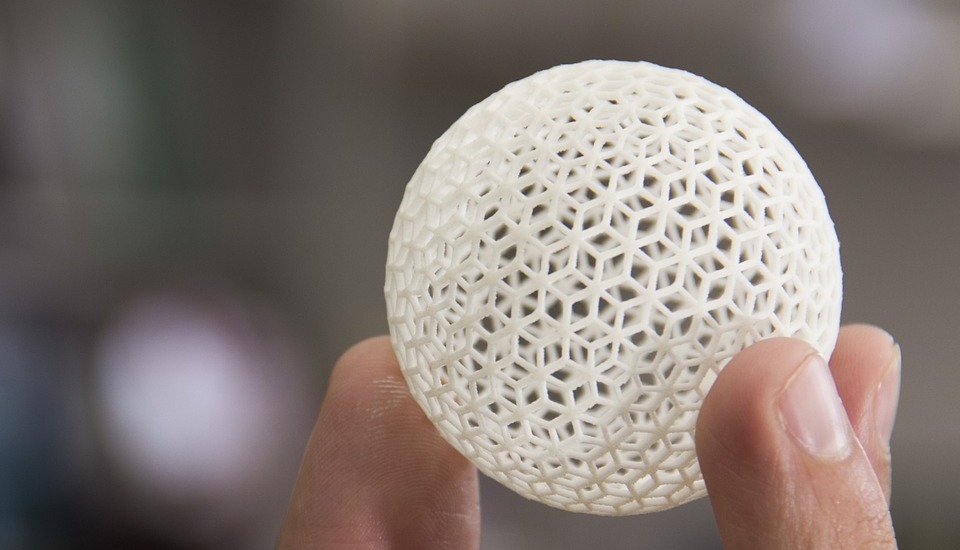

In the field of 3D printing, HIPS is probably most commonly known as an excellent support material. Why will you need a support material, you may ask? If you were to 3D print a complicated design with overhang features, you will probably need to incorporate support structures of some sort into the design. This is mainly due to the functional limitations of 3D printers, making it necessary to print objects in layers from the bottom up. Thus, overhanging features will require supports underneath them to avoid warping, deformation, or a collapse.

HIPS is an excellent support material, especially when printing using ABS. This is because of the capability of HIPS to dissolve readily in limonene, an easily obtainable solvent that is derived from the skin of lemons. A print made from ABS with support structures made from HIPS only needs to undergo a 24-hour soaking limonene for the support structures to fully dissolve – no need for knives, sanding, or scraping. The result is a smoother, blemish-free print without a lot of manual work.

Why do we say the HIPS works best with ABS? This is because the printing temperatures of HIPS and ABS are nearly identical. This means that there will not be a risk that either one will deform due to differences in temperature.

HIPS and ABS also have very similar physical properties, making HIPS an excellent material for 3D printing even on its own. In terms of density, tensile strength, and hardness, HIPS stands shoulder to shoulder with ABS. This means that a HIPS filament is a perfectly fine material for 3D printing if you need a soluble product that is easily sanded, machined, painted, and glued.

How do you work with HIPS?

HIPS prints best at a temperature range of 230 to 240 °C. If the nozzle temperature is too low, the HIPS filament will not liquefy properly and will result in under-extrusion. Next, the temperature of the printing bed should be kept within a range of 90 to 110 °C. To ensure adhesion of the HIPS to the printing bed, using a Kapton Tape or Kapton Spray is recommended.

HIPS can be used at high printing speeds of up to 70 mm/s, but best results are achieved with low speeds (less than 40mm/s). This is especially important when printing designs with intricate details.

After the print job, you need to allow the print to cool off completely. A 3D print made with HIPS is very prone to warping when not completely cooled off. We recommend keeping the cooling fan at a low speed, or even turned off completely. Gradual cooling off will reduce the risks of warping in the product.

If you are using HIPS as a support material, you only need to submerge the print completely in limonene for at least 24 hours. Gently shaking the container every now and then can help speed up the dissolution process.

What are the disadvantages to working with HIPS?

As we have mentioned, HIPS is an excellent choice for support material when working with ABS. How about when working with PLA? PLA has much lower printing temperature than HIPS, making them very incompatible. We recommend polyvinyl alcohol (PVA) as an alternative support material for PLA prints, as they have similar printing temperatures. PVA dissolves readily in water.

As a filament material for the print, using HIPS will also introduce a few challenges. As already mentioned, HIPS will work best with a heated printing bed to avoid warping. It has also been suggested to use a heated chamber when working with HIPS. These requirements, coupled with the high printing temperature of HIPS, make working with HIPS an energy-intensive process. HIPS also emits a light odor due to the release of styrene, so we recommend printing in a well-ventilated room.

What is the best brand of HIPS filament?

The popularity of HIPS has started to grow, as it has come out a feasible alternative to the more common PLA and ABS. True to form, many manufacturers have come out with their own HIPS filament products.

The HIPS filaments sold by GizmoDorks is one of the best-selling right now. They are available in 1.75mm and 3mm sizes, and can be purchased in 1kg spools.

MatterHackers also has their own HIPS filament products, that are also available in 1.75mm and 3mm sizes. Their products are available in black or white, and can be purchased in 1 kg spools.

FormFutura has 2 types of HIPS filament products. Their LimoSolve line has a natural (white) color and does not come with any additives, making it especially appropriate for dissolving in limonene. Their EasyFil line is sold for those who want to use HIPS as build material. It is slightly softer and more flexible than standard HIPS filaments, resulting in products that are more durable and has higher impact resistance. Their EasyFil filaments are available in white, black, gray, red, and dark blue.

Finally, the eSun HIPS filament products sold on the Lulzbot online store probably has the greatest variety of colors. The filaments are only available in 3mm sizes and 1kg spools, but have a dazzling selection of 14 colors. This variety is perfect if you are looking to make prints that are 100% HIPS.

The Roundup

| Material | High Impact Polystyrene (HIPS) |

| Applications | – Primarily as support material for ABS builds – Can also be used on its own |

| Properties | – Stronger than standard polystyrene – Durable but flexible – Has high impact resistance – Lightweight – Waterproof |

| Dissolves in | Limonene solvent |

| Recommended printing temperature | 230 to 240 °C |

| Recommended bed temperature | 90 to 110 °C |

| Bed adhesion | Kapton Tape or Kapton Spray |

| Speed | As high as 70 mm/s, but recommended speeds are 40mm/s or less |

| Cooling | Cooling fan is not recommended, but can be used at low speed |

HIPS gained popularity as an excellent support material for prints that use ABS, but its popularity as a standalone filament material has also started to gain traction. Prints made from HIPS are strong and flexible, durable without being brittle, and have excellent impact resistance. If you are looking for a new dimension in 3D printing, then we suggest playing around with HIPS. You might be pleasantly surprised.