How much does a 3D printer cost?

Let’s say you’re interested in buying a 3d printer. Although the technology has only just started to focus on the masses – that is the consumer market – there are already lots of different models from different manufacturers for sale. They all have their pros and cons, so you need to know which one will give you the best value for money.

Don’t Miss: Best 3D Printers of 2017

So, how much does a 3d printer cost?

When asked: ‘how much does a 3d printer cost?’, I’d say the answer isn’t that simple to obtain. The key questions you should be asking yourself is: ‘what will I be using it for, and how much will I be using it?’. Since there are different types of 3d printers, like extrusion or granular types, with their respective filament (-prices), the actual 3d printer price consists of multiple factors. In this article, I’ll try to make it as transparent as possible.

Check Amazon for 3D Printer Prices

Click the button below to check Amazon for the latest price information.

For home or professional use?

The first step in buying a 3d printer is to narrow the field of view to the models that suit your needs best. If you are new to the subject and want to start learning how to make your first prints, then don’t let the prices of the industrial-type machines scare you away! For home use, a basic 3d printer price starts around $1000. In comparison, an industrial printer starts at around $250.000. The high-end Stratasys Fortus 900MC will set you back at least $750.000.

The first step in buying a 3d printer is to narrow the field of view to the models that suit your needs best. If you are new to the subject and want to start learning how to make your first prints, then don’t let the prices of the industrial-type machines scare you away! For home use, a basic 3d printer price starts around $1000. In comparison, an industrial printer starts at around $250.000. The high-end Stratasys Fortus 900MC will set you back at least $750.000.

In order to provide the most useful buyers advice, I’ll stick with the 3d printers for home use. So, now that you’ve got an idea of the price possibilities, let’s move on to the next step.

Which type should you buy?

Next up, you should decide what material you will be using to print. The most popular filaments are ABS, PLA and HDPE plastic, which each have their advantages and drawbacks. If you’re not familiar with their properties, let this article help make up your mind.

Irrespective of which filament you choose, the designs you can choose from stay equally abundant. Visit Thingiverse to take a look at the possible designs.

The running costs

So, in order to keep printing, you will need to buy the plastics. Luckily for you, there are already lots of places where you can buy spools of plastic. ABS and PLA starts at roughly $25 per kilogram. With one spool you should be able to print about 500 chess pieces, so cost-wise it’s pretty awesome.

Making a selection

Hopefully you’ve now got an idea about how much a 3d printer costs to buy and to use it. To help you get started in choosing the right type and model, I’ve selected a few popular 3d printers that provide the best value for money.

Best budget 3d printer

It might not be the cheapest model available, but the Solidoodle 3rd Gen. is certainly one with the best value for money. At $799, it offers a 8 x 8 x 8 inch heated print-bed, which offers a more stable print quality.

Best DIY model

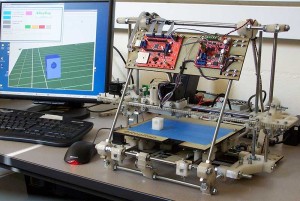

If you’re the kind of person who likes to tinker around on his machines, you might fancy the Maker’s Tool Works MendelMax. For $1599, you get a DIY-kit that offers everything you need to make this Reprap Mendel. Don’t have the cash? Just download the plans and start making it from scrap lying around in your garage!

For the novice users

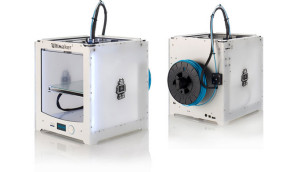

For those in search of more possibilities and more ease-of-use, take a look at the Ultimaker Replicator 2. Starting at $2199, this baby rocks a large (11.2 x 6 x 6 inches) print area, and comes with its own 3d-model handling software so that you can concentrate on the fun stuff.

Why the phenomenal price on a Stratasys Fortus 900MC? It’s build volume is 3 times the height of an Ultimaker, 2 times the height of an Ultimaker Extended, uses ABS, but is 375 times the price.

This can be for many reasons,

One for example would be the precision it works with. Or possibly the technology it works with.

It might use laser sintering for example, which is a lot more precise and when holding the completed object you wouldn’t realise that it was 3D-printed as it will be a homegenous mass with now visible grooves.

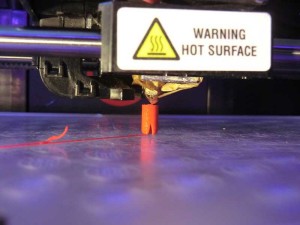

A Makerbot uses the extrusion or FDM method, these printers squeeze out hot, molten plastic that then sticks to the previous layer. Once finished printing you will clearly see the grooves and the individual layers. It’s fine to create small, fun things but it is not of the standard to create items ona professional stage.

(Google, 3d printed jaw implant) this will show you the incredible precision and possibilities possible with high-end printers.

Hope this helped!

Best Regards,

Thomas

It does. Thank you.

No prices listed for them. I’m assuming these are for high end business only.