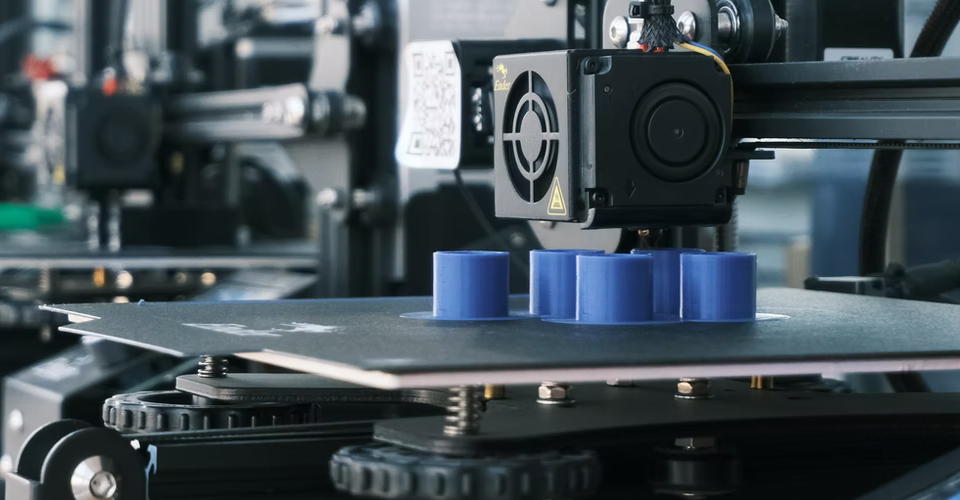

How to Fix A Clicking Noise in Your 3D Printer Extruder

A 3D printer is naturally very noisy when it is running. Most of this noise comes from the printer’s fan and stepper motors. However, there may be some noises that are considered out of the ordinary and may require some of your attention. A good example of this is a clicking noise coming from the extruder.

The clicking noise likely comes from the stepper motor continuing to rotate while the extruder gear is held stationary. This “skipping” of the motor can be because of several possible reasons – a clog in the nozzle, trapped debris in the extruder gears, or improper printer settings. Diagnosing the problem first is key to coming up with a solution.

Fixing a clicking sound from your extruder is going to be a multi-step process. The most practical troubleshooting method would be to try the more benign solutions first before moving on to the ones that require taking apart your printer’s extruder assembly.

The nozzle is too close to the bed

Any mechanical obstruction can cause the extruder to “skip” because pushing the filament forward becomes too difficult. A common culprit is the bed or the build plate. If the starting position of the nozzle is too close to the bed, the filament may not be able to flow freely from the nozzle.

To rule out this cause, it would be a good idea to level your bed. You can do this manually by inserting a piece of index card between the nozzle and the build plate. You want the card to fit snugly but just enough so that it can still be moved. Do this on all four corners and the center of the build plate while adjusting the level as needed.

Of course, this step will take almost no effort if your 3D printer comes with an auto-leveling feature.

If this still does not fix the problem, you can consider adjusting your Z-offset settings. This determines the initial distance of the nozzle from the print bed. The best value for Z-offset can vary across different filament types, but it is often a fraction of the layer thickness value.

Increasing the Z-offset should make extruder skipping less likely. However, an excessive Z-offset can also lead to bed adhesion problems. The best solution is to adjust the Z-offset by 0.05 millimeters and do a test print. Repeat this until you are satisfied with the results.

Take note that a print bed that has been damaged or warped will almost certainly lead to extrusion or bed adhesion problems. If this is the case, the best solution would be to replace your print bed entirely. You can also consider using a glass build plate as it does not warp.

Low printing temperature

If your filament is not being melted quickly enough in the melt zone, then the extruder will also have more difficulty in pushing more filament forward. Check the recommended temperature values for your filament. Do you still have room to increase temperature values? Then you can try to do so in 5 °C increments. If this is the cause of the clicking sound, then it should get resolved almost instantly.

As with most other 3D printer settings, setting your filament temperature too high can have some negative outcomes. If you’re printing a highly detailed model, you may end up losing some detail precision by printing too high. Don’t push a filament to its temperature limits just because of a clicking sound – look for a solution elsewhere.

High printing speed

This solution somewhat goes hand-in-hand with adjusting printing temperature. If the temperature can no longer be changed, you can consider lowering the printing speed. This reduces the pressure on the extruder gears and makes them less likely to skip.

Not only can this possibly resolve the clicking sound in your extruder, but it should result in a more consistent extrusion rate. Slow and steady is always a good setting while 3D printing. The only problem is that it will make your printing time significantly longer. If you’re not in a hurry, there is no harm in reducing the printing speed.

Nozzle is clogged

There are many possible reasons for a nozzle to get clogged. It may be due to residual filament that has hardened inside the nozzle. It can also be caused by dirt or residue in the filament that got burnt in the extruder assembly. In any case, a clogged nozzle presents a typical mechanical obstruction that makes extrusion more difficult.

A clogged nozzle is a common problem in 3D printing. It can also be one of the most frustrating. If you’re lucky, you can clean out a clogged nozzle from the outside using a brush with steel or brass wires. You can also try pushing out the clogged material with a pin.

The “cold pull” method is one of the more reliable solutions to a clogged nozzle. To do this, you will have to disassemble the extruder assembly so that you can manually push in some filament through the nozzle. You will need to use a high-temperature filament – Nylon works best, but ABS is also a good option.

Heat the nozzle to about 250 C and leave it at this temperature for about 5 minutes. Gently but firmly push the ABS or Nylon filament through the nozzle. Any of the molten residue material in the nozzle should be extruded along with the filament. Continue doing this until the filament no longer comes out with any black specks or discoloration.

Allow the filament in the nozzle to re-solidify by cooling to room temperature. This should help remove any of the hardened deposits inside the nozzle. You will then want to heat the nozzle but only to around 120 C. This will soften the filament just enough so that you can yank it out of the nozzle. Do this “cold pull” firmly and forcefully. You will likely see some blackened deposits stuck to the filament.

If all else fails, you can just remove the nozzle from the heater block and soak it in some acetone. Just a few minutes in acetone should be enough to remove any stubborn residue. Make sure that all the acetone has evaporated off the nozzle before you reinstall it.

Improper extruder gear and idler assembly

The extruder gear and idler work in tandem to “grab” the filament and convey it towards the nozzle. For this assembly to do its job, the components have to be in the proper position and orientation. While these generally stay put, some idler and gear maintenance may be in order if you’re hearing clicking sounds.

There are two factors to consider here – tension and alignment. Tension refers to how closely spaced the idler and extruder gear are. You want them to be close enough to grab the filament but not too close that extruder gear encounters difficulty in rotating. An over-tightened idler may be a reason for the clicking of the extruder gear.

You also want to make sure that the extruder gear is aligned both with the extruder opening above and the PTFE tube below. This ensures a smooth and unobstructed flow of the filament from the extruder to the hot end.

Adjusting the idler and gear assembly involves making very small changes. This is something you will have to do by feel. If you have tried all the previous fixes and still hear clicking sounds, then turning a few screws on the extruder assembly may be worth exploring.

Damaged PTFE liner

The internal PTFE liner in an extruder plays a vital role in ensuring that filament flow proceeds with as little friction as possible. This PTFE liner can get damaged over time and will need to be replaced. It’s quite rare for a damaged PTFE liner to be problematic enough to cause a clicking of the extruder, but it’s still worth investigating.

If you’ve already taken apart your extruder, then just take the time to inspect the condition of the PTFE liner. Is there some discoloration or parts that have been visibly nicked? A replacement will be recommended if this is the case. Fortunately, PTFE liners are pretty cheap and easy to replace.

Stripped filament

When there is too much tension between the extruder gear and the idler, it can result in some of the filament material getting stuck in the hobs of the gear. This is what is referred to as the “stripping” of the filament and will eventually result in an extrusion failure. If the stepper motor of your extruder continues to rotate without any filament exiting the nozzle, it is very likely due to stripping.

The trouble with this stripping is that there really is no solution other than to take apart the extruder assembly. You will need to manually clean the extruder gears and get rid of the material that has been stuck in the hobs.

Cleaning is the easy part of this fix – you will need to pay more attention to taking the assembly apart and putting it back again properly. As mentioned earlier, make sure to set the idler and extruder gear at the proper tension and alignment.

Final thoughts

If you’ve already spent significant time with your 3D printer, then you’re probably already aware of some signs that something is going wrong. A clicking sound from the extruder is an example of a sign of a problem that needs to be addressed. In fact, you may want to pause an ongoing project if you hear a constant clicking – you’re unlikely to get a good output, anyway.

With proper maintenance and double-checking of your printer parameters, it is possible to entirely avoid encountering this clicking sound. We recommend regular bed leveling, scheduled cleaning of the nozzle and extruder assembly, and periodic replacement of PTFE liners.