What is injection molding?

Looking to manufacture a large number of units of the same product? Do you want to manufacture them at the very low cost per unit? If you answered yes to both those questions, then the injection molding technique is worth looking into. Injection molding is used to create all sorts of products like electrical housings, auto interior parts, bottle caps, etc.

Injection molding and the mold

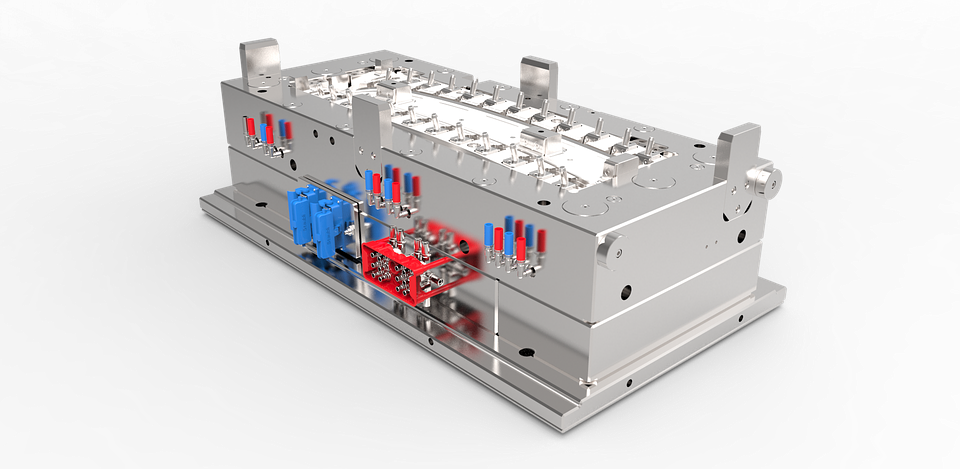

Injection molding essentially involves injecting a melted plastic mixture into the cavity of a tightly held mold. The injected plastic is hot when injected and cools down to take the shape of the mold. The mold can be designed and made to suit any shape or size of the end product that you are trying to manufacture. Designing and creating a mold is a complex high-skill process. Either aluminum or steel is used to create the mold. Molds can be designed to produce identical copies of one part, or they can be designed to produce multiple parts that fit together.

Material used to inject inside the mold

The plastic material used for injecting is of two types. One is called thermosetting and the other is called thermoplastic. The thermosetting plastic cures permanently and then burns if you try to melt it again. Hence, once it is cured, a thermosetting plastic cannot be re-used. A catalytic reaction is used to prepare the thermosetting plastic. Epoxy, polyester, and phenolic resins are some examples of thermosetting plastics. Thermoplastics, on the other hand, can be melted, cooled, solidified, and then re-melted again. Nylon and polyethylene are examples of thermoplastics. With almost twenty thousand different plastic compounds available today for the injection molding process, you can be confident that almost any manufacturing requirement can be fulfilled by injection molding. Even hot glass can be used for injection into a mold.

The actual process

Injection molding involves three main machines: a feed hopper, a heat barrel, and a reciprocating screw or ram. First, plastic is fed into the hopper. This plastic is in powder or granular form. Next, the plastic enters the heat barrel from the hopper where it gets melted due to a frictional action of the reciprocating screw. Finally, the molten plastic is injected into the injection cavity of the mold. When the plastic cools down inside the mold, the mold opens up and ejector pins push out the part. There are certain materials like silicone rubber which are already in liquid form when placed inside the feed hopper. Hence, they do not need any heating.

Injection mold machines are rated for clamping pressure of the molds. Depending on the viscosity of the plastic and the part being created, one would need an injection molding machine with the appropriate pressure rating. For example, a 100-ton machine would provide a clamping pressure of 100 tons to the molds. This pressure is important because if the pressure is not high enough, then the liquid may flow out (this action is called flashing), while too much pressure may affect the quality of the end product.

Pros and Cons of injection molding

Since injection molding is a very scalable and repeatable process, the end result is that you get identical parts in high volumes. If you are manufacturing critical parts that need high quality and consistency specifications, or if your brand reputation demands consistency in the product, then injection molding can help you achieve those goals at scale. Injection molding can also match any physical properties desired because there are a large number of plastic compounds available to inject into the mold. Lastly, injection molding is a relatively more environmentally friendly process than some other manufacturing processes. There is a low amount of scrap produced in the process of injection molding, and depending on the type of plastic used, the remaining material or scrap material can be crushed, re-melted, and re-used again.

Though injection molding has its benefits, there are some downsides as well. Injection molding is an expensive process at the beginning. One has to first design and prototype the product. Once that happens, the next step is to design and prototype the mold. After certain testing and iterations, the final mold is prepared. All of the testing, iterations, and mold creation takes a reasonable amount of time as well. Secondly, injection molding machines have size limits. Hence, if your manufactured item is large or complex, then you may need to create multiple pieces and then fix them all together to get the final product ready.

Factors to consider

Some factors that you need to consider when trying to figure out which manufacturing process to use are:

High fixed cost: You must understand that preparing for an injection molding process will cost you a decent amount up front. You must be ready to spend that amount, and then try and spread the cost out over a large number of units. Your fixed cost initially is going to be quite high.

Large volume: Because of the high initial setup costs, you will want to manufacture a large number of units to break even. If you are planning to manufacture just a few units, then you will have to re-consider injection molding and maybe look at another process which is more economical. Ultimately, in order to have a low per unit cost, you will need a high volume if you are going to use injection molding.

Design of the product: From the first day itself, you will have to design your product keeping in mind the limitations of the injection molding process. While injection molding does allow a large variety of products to be manufactured, the possibilities are not unlimited. You will have to design the product in a way that makes things simple and does not require you to bond multiple units later on or make the production cost more expensive. Assembly cost can add up after all. The planning will have to focus on keeping things simple and being most efficient.

Time: Keep in mind the time it will take to prepare the injection mold and then to actually run the manufacturing batches. You will have to work according to a schedule and plan all the phases out to ensure that your product is manufactured in time for delivery.

Identical product: If you are manufacturing the identical product with the same specifications at a very large scale, then injection molding is the best and most economical way to do so. If your product has variations and a large number of units are not identical, then you will have to look at some other process because injection molding will be an expensive affair. You will have to make new molds for new variations and that will cost you a lot of money.

Uniform thickness vs variable thickness: Most of the parts manufactured via injection molding tend to be of uniform thickness. If a product has varying degrees of thickness at various locations on the body, then the injection molding tool design will have to be engineered accordingly. One will have to ensure that the cooling of the plastic happens in a uniform manner across various thickness levels. All of this will increase your initial design and setup costs. So, keep in mind the thickness levels and the variation in the thickness of the product before exploring the manufacturing processes.

Conclusion

Overall, injection molding is a good manufacturing process for making products that have already been tested and prototyped. Products that are in the final stages of its development and are ready to be mass produced are appropriate for injection molding. Products which are still under research and development, and are in the initial stages of its development would be better created using other techniques such as 3D printing. Prototypes and product variations can be made much more cheaply in a 3D printing process. For a final end product, injection molding is a great option to consider.

FAQs

How long does it take to design and create a mold?

Depending upon the complexity and design of the mold, it may take anywhere from a few weeks to a few months to build the final mold. Normally, it may take 10 weeks or so, but the highly complex designs can push that time to 5 or 6 months as well.

What are mold classification and type numbers?

Molds are classified as per SPI standards depending on the number of units it will be used to manufacture and the grade of material from which it is made. There are 4 types:

Type 101 – Most expensive and made of the highest grade material. Good for producing over 1 million units

Type 102 – Expensive and made with high-end material. Good for producing over 500,000 units

Type 103 – Mid-range and made with moderate-grade material. Good for producing over 100,000 units

Type 104 – Budget option and made with low quality material. Good for producing 10,000 to 50,000 units.

How does one mold plastic using the injection molding process?

Plastic is first melted. Then it is injected with a certain pressure into the cavity of a custom-designed mold. The plastic enters the mold and then cools down, taking the shape of the mold. Finally, the mold is opened and the molded product is removed using ejector pins.

How do I know that my product will be best manufactured using the injection molding technique over other processes?

First of all, if your intention is to manufacture large quantities of the same product, then that is the first check. Secondly, if you want to reduce your per unit cost as your volume grows, then that is the second check. Thirdly, if your design is complex, then most other processes will get ruled out leaving you with injection molding as one of the very few options. Lastly, if you are ok with using plastic or glass as the material for your product, then injection molding fits your requirement.

What sizes of products can be made using injection molding?

You will have to discuss your requirement with an injection molding manufacturer to know the exact answer. Normally, for thermoplastic material, the size ranges from less than 1 oz to a maximum of around 700 oz. If thermosetting material is being used, then the size ranges from less than 1 oz to a maximum of around 200 oz.

Within the injection molding process, what are the different types of variations?

There are quite a few different variations within the injection molding process. They are as follows:

- Co-injection (sandwich) molding

- Injection-compression molding

- Gas-assisted injection molding

- Reaction injection molding

- Fusible (lost, soluble) core injection molding

- In-mold decoration and in-mold lamination

- Insert and outsert molding

- Lamellar (microlayer) injection molding

- Resin transfer molding

- Low-pressure injection molding

- Micro injection molding

- Multicomponent injection molding (also known as overmolding)

- Microcellular molding

- Multiple live-feed injection molding

- Powder injection molding

- Rheomolding

- Structural foam injection molding

- Push-Pull injection molding

- Structural reaction injection molding

- Thin-wall molding

- Rubber injection

- Vibration gas injection molding

- Water-assisted injection molding

- Injection molding of liquid silicone rubber

What are the different types of molding defects?

There are a few different types of defects seen in the injection molding process. They are as follows:

- Blister

- Burn Marks

- Color Streaks

- Delamination

- Flash

- Embedded Contaminates

- Flow Marks

- Jetting

- Polymer Degradation

- Sink Marks

- Short Shot

- Splay Marks

- Stringiness

- Voids

- Weld Line

- Warping

What is the tolerance level in the injection molding process?

Tolerance levels in the injection molding process vary between +- 0.002 to +-0.008.

Can I modify the mold after the first production run?

If the final product is not as per your requirements, then it may necessary to modify or change the mold. It is possible to modify the mold, especially if it is made of steel. However, you will have to consider the cost of modifying vs the cost of creating a new mold altogether. In some cases, it may be better and more economical to simply create a new mold.